Combined removal method for contaminants from coal-fired flue gas and special purification reactor thereof

A combined removal and coal-fired flue gas technology, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, to achieve the effects of eliminating adverse effects, low cost, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

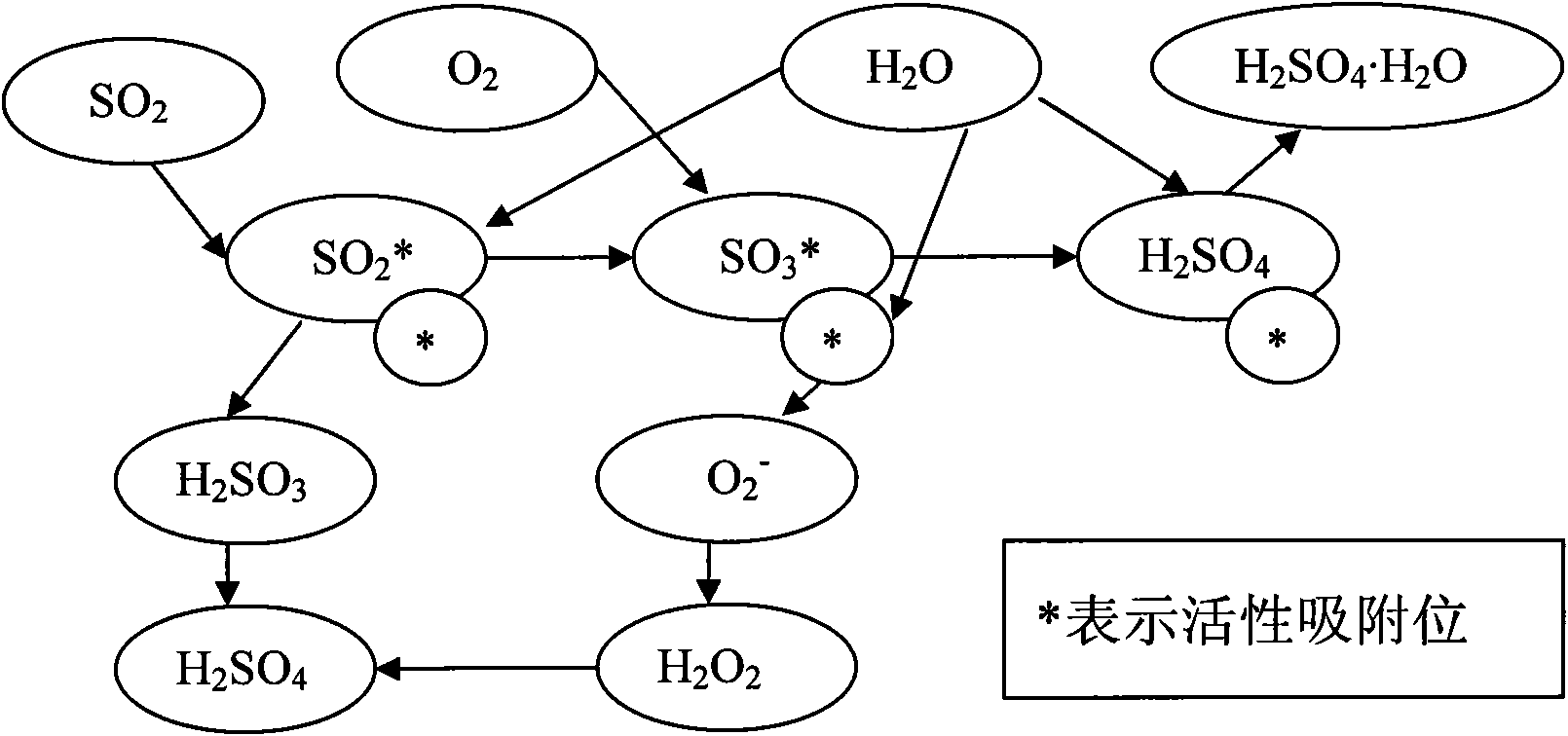

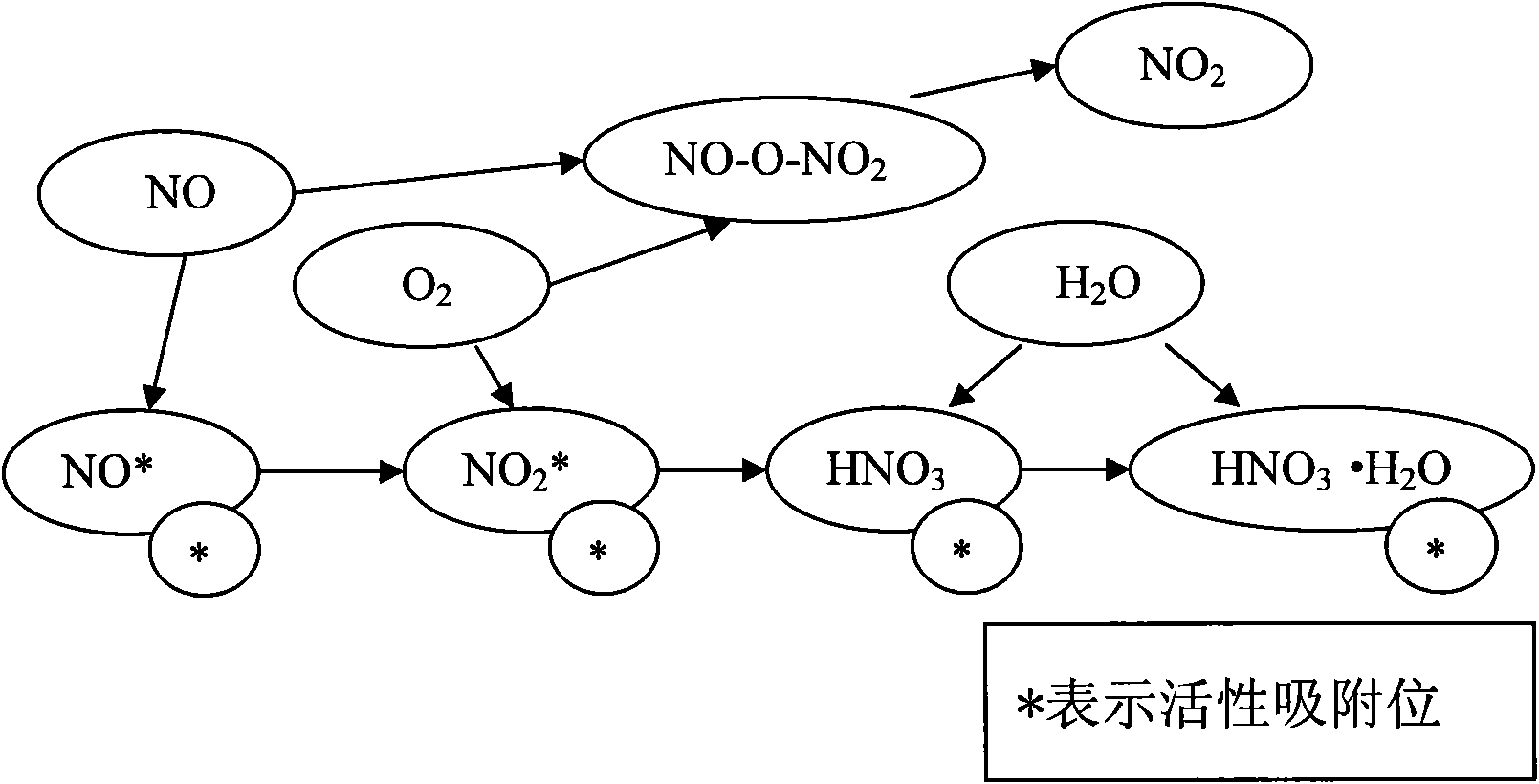

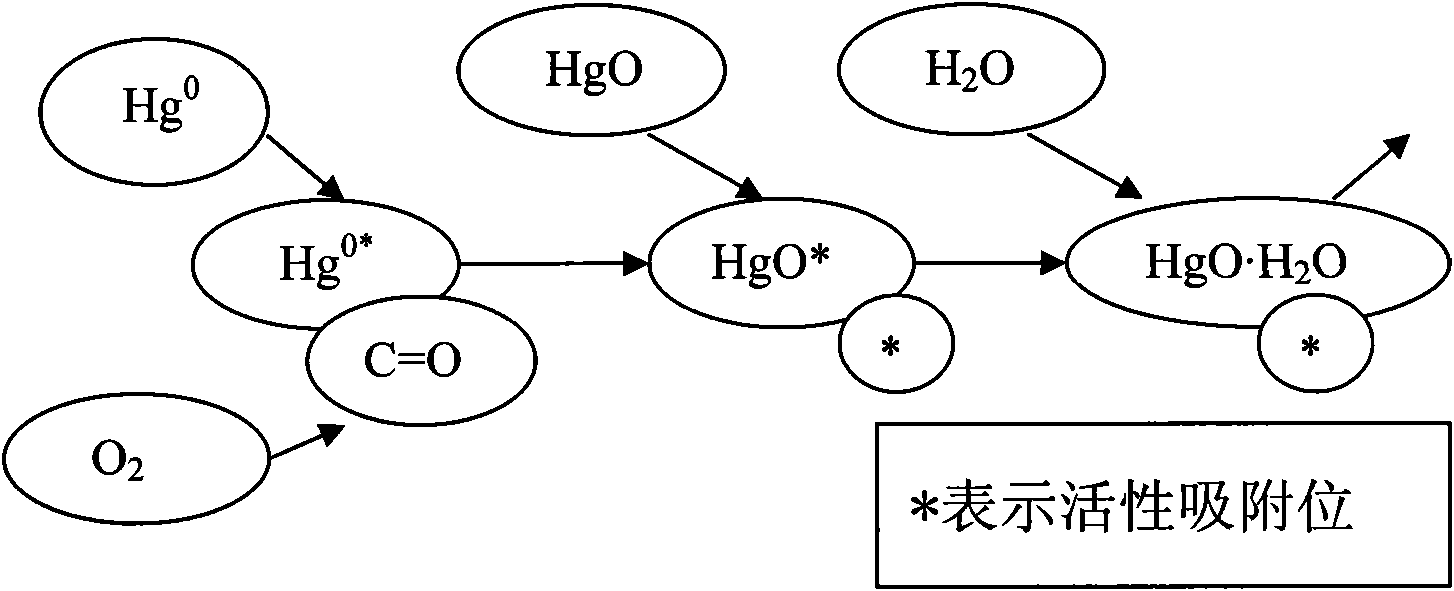

Method used

Image

Examples

Embodiment 1

[0050]The flue gas at the tail of the coal-fired boiler after high-efficiency dust removal is cooled to 145°C through a heat exchanger, and then passed into the first-stage purification reactor loaded with modified activated carbon fibers, and the gas supply volume of the steam generator and the reactor are adjusted. The injection amount of atomized water in the reactor is kept at 90°C, the volume content of water vapor in the flue gas is 12%, the volume content of oxygen in the flue gas is 10%, and the sulfur dioxide and Sulfur trioxide, elemental mercury and its compounds, volatile organic pollutants in flue gas are oxidized and decomposed into carbon dioxide and water, and other heavy metals are dissolved in SO 2 In the sulfuric acid droplets formed after oxidation.

[0051] The flue gas discharged from the first-stage purification reactor is introduced into the second-stage purification reactor loaded with modified activated carbon fibers through the pipeline, and the in-l...

Embodiment 2

[0056] The flue gas at the tail of the coal-fired boiler after high-efficiency dust removal is cooled to 120°C through a heat exchanger, and then passed into the first-stage purification reactor loaded with modified activated carbon fibers to adjust the gas supply of the steam generator and the reactor The injection amount of atomized water in the reactor is kept at 55°C, the volume content of water vapor in the flue gas is 8%, the volume content of oxygen in the flue gas is 7%, and the sulfur dioxide and sulfur dioxide in the flue gas are removed. Sulfur trioxide, elemental mercury and its compounds, volatile organic pollutants in flue gas are oxidized and decomposed into carbon dioxide and water, and other heavy metals are dissolved in SO 2 In the sulfuric acid droplets formed after oxidation.

[0057] The flue gas discharged from the first-stage purification reactor is introduced into the second-stage purification reactor loaded with modified activated carbon fibers through...

Embodiment 3

[0062] The flue gas at the tail of the coal-fired boiler after high-efficiency dust removal is cooled to 80°C through a heat exchanger, and then passed into the first-stage purification reactor loaded with modified activated carbon fibers to adjust the gas supply of the steam generator and the reactor The injection amount of atomized water in the reactor is kept at 30°C, the volume content of water vapor in the flue gas is 6%, the volume content of oxygen in the flue gas is 5%, and the sulfur dioxide and Sulfur trioxide, elemental mercury and its compounds, volatile organic pollutants in flue gas are oxidized and decomposed into carbon dioxide and water, and other heavy metals are dissolved in SO 2 In the sulfuric acid droplets formed after oxidation.

[0063] The flue gas discharged from the first-stage purification reactor is introduced into the second-stage purification reactor loaded with modified activated carbon fibers through the pipeline, and the in-line heater arrange...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Gap width | aaaaa | aaaaa |

| Specific area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com