System and method for reclaiming sludge heavy metals

A recovery system and technology for heavy metals, applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of high cost and low recovery rate, and achieve low cost, less energy and less energy. Effects of Environmental Pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

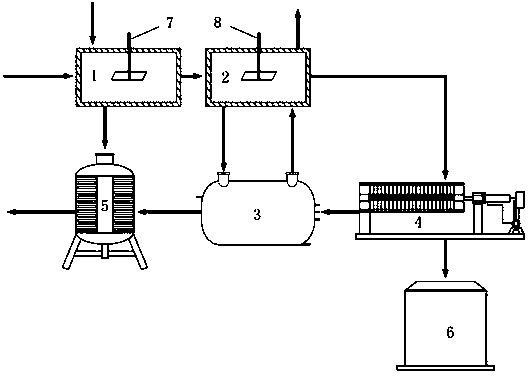

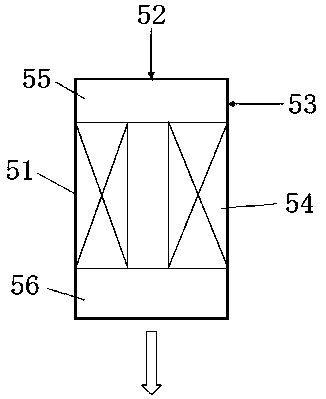

[0037] Such as figure 1 As shown, the sludge heavy metal recovery system of the present invention includes an alkali washing chamber 1, a backwash chamber I2, a reclaimed water treatment system 3, a plate and frame filter press 4, an ion exchange system 5, and a drying chamber 6. The washing chamber 1 is equipped with a stirrer I7, and the alkaline washing chamber 1 is connected to the ion exchange system 5 through pipelines, and is used to transport the heavy metal-containing upper alkaline washing waste liquid after the alkaline washing sedimentation to the ion exchange system 5, the alkaline washing chamber 1 The waste residue after the reaction sedimentation is sent to the backwash chamber I2;

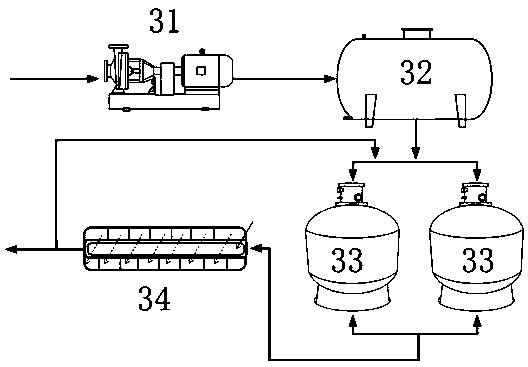

[0038] The backwash chamber I2 is provided with a stirrer II8. The backwash chamber I2 is connected to the reclaimed water treatment system 3 through a circulating pipeline system, and the backwash wastewater is transported to the inlet of the reclaimed water treatment system 3 to rece...

Embodiment 2

[0054] Example 2 Experiment

[0055] The sludge sample was taken from the Guiyang Xiaohe Sewage Treatment Plant. The sludge sample was recovered by the method of Example 1 of the present invention, and the heavy metal content in the sludge was detected by the atomic absorption method (determined after digestion). The results are shown in the table 1 shows:

[0056] Table 1 Comparison of heavy metal content in sludge before and after treatment

[0057]

[0058] It can be seen from Table 1 that using the method of the present invention to perform heavy metal recovery processing on sludge samples can realize heavy metal recovery and promote the harmlessness of sludge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com