Method for producing fuel ethanol by utilizing papermaking sludge

A technology for papermaking sludge and fuel ethanol, which is applied in the fields of solid waste resource recycling and environmental protection, can solve the problems of increased papermaking sludge production and energy shortage, and achieve the goal of promoting the peak of gas production, shortening the fermentation cycle, and highly operable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

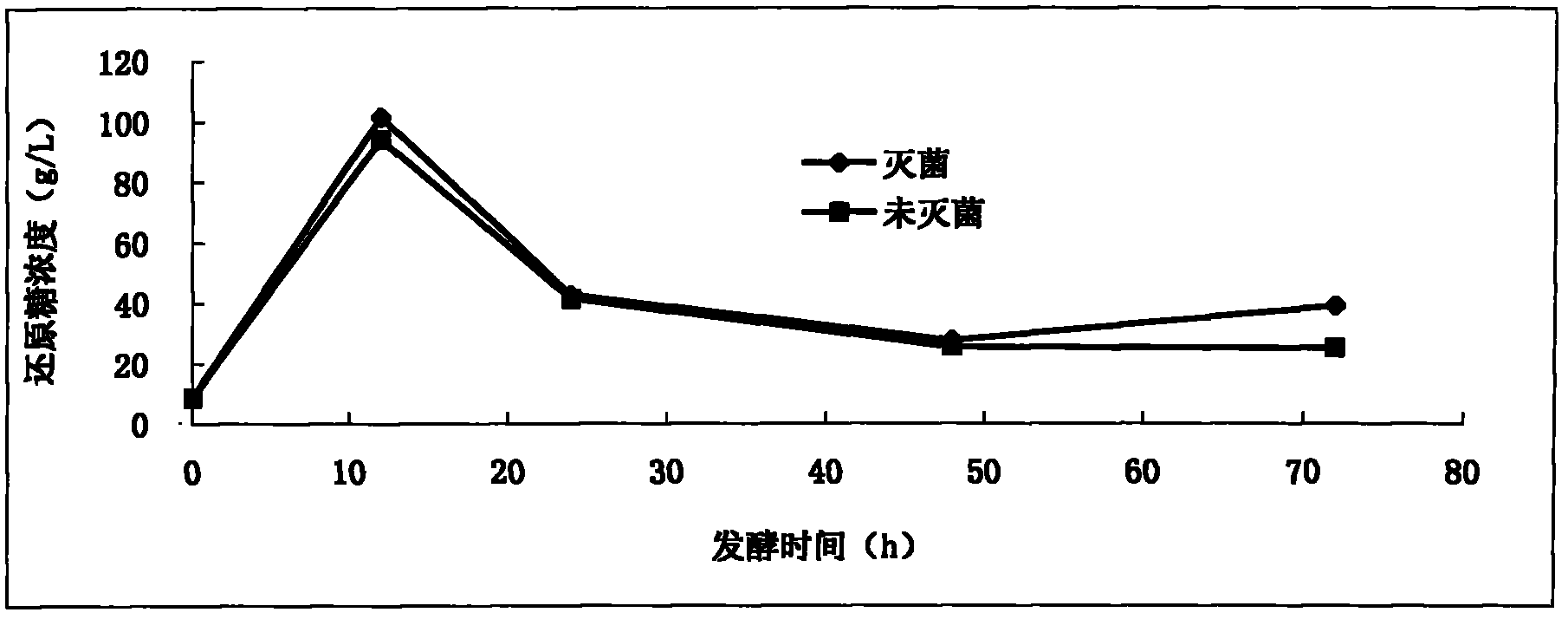

Embodiment 1

[0046] Example 1: Production of fuel ethanol using papermaking sludge

[0047] The papermaking sludge used in this example is taken from a paper mill in Guangdong Province, and papermaking sludge from other paper mills can also be used, which is one or more of pulping wastewater, papermaking wastewater or domestic sewage of paper mills. In the biochemical treatment process, the mixed sludge obtained in the primary settling tank and the secondary settling tank has a water content of 70-80%.

[0048] The monosodium glutamate waste liquid used in this example is taken from a certain monosodium glutamate factory in Guangdong Province, and can also use the monosodium glutamate waste liquid from other monosodium glutamate factories. Mixtures in any proportion.

[0049] (1) Uniformly disperse the retrieved fresh papermaking sludge;

[0050] (2) According to monosodium glutamate waste liquid: papermaking sludge=6: 100 (w / w, by dry mass), take fresh monosodium glutamate waste liquid,...

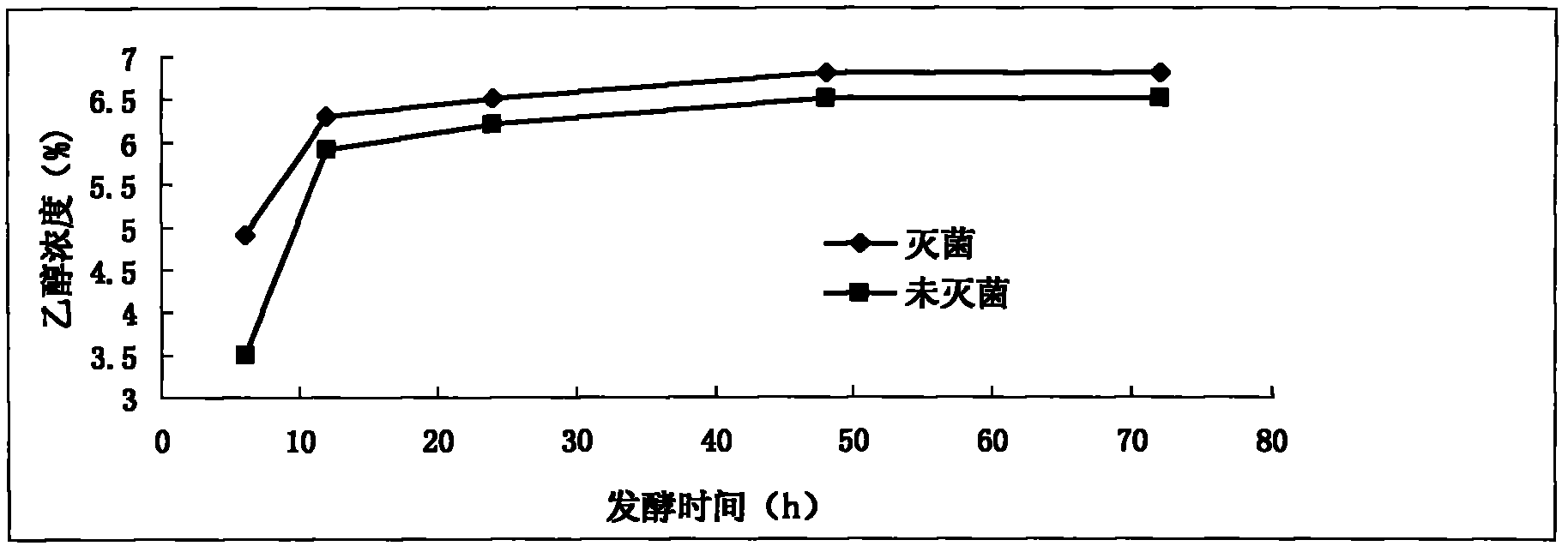

Embodiment 2

[0060] Example 2: Production of fuel ethanol using papermaking sludge.

[0061] The papermaking sludge used in this example is taken from a paper mill in Guangdong Province, and papermaking sludge from other paper mills can also be used, which is one or more of pulping wastewater, papermaking wastewater or domestic sewage of paper mills. In the biochemical treatment process, the mixed sludge obtained in the primary settling tank and the secondary settling tank has a water content of 70-80%.

[0062] The monosodium glutamate waste liquid used in this example is taken from a certain monosodium glutamate factory in Guangdong Province, and can also use the monosodium glutamate waste liquid from other monosodium glutamate factories. Mixtures in any proportion.

[0063] (1) Uniformly disperse the retrieved fresh papermaking sludge;

[0064] (2) According to monosodium glutamate waste liquid: papermaking sludge=10:100 (w / w, by dry mass), take fresh monosodium glutamate waste liquid...

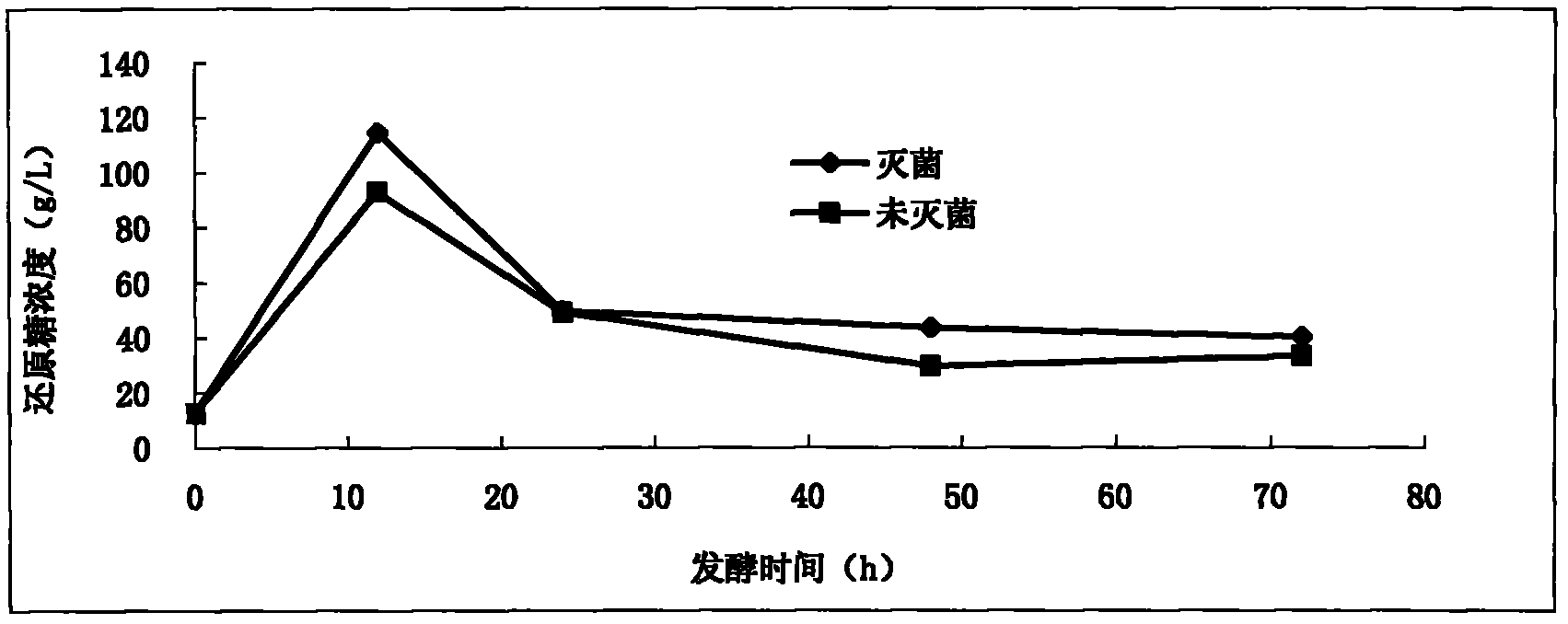

Embodiment 3

[0074] Example 3: Production of fuel ethanol using papermaking sludge

[0075] The papermaking sludge used in this example is taken from a paper mill in Guangdong Province, and papermaking sludge from other paper mills can also be used, which is one or more of pulping wastewater, papermaking wastewater or domestic sewage of paper mills. In the biochemical treatment process, the mixed sludge obtained in the primary settling tank and the secondary settling tank has a water content of 70-80%.

[0076] The monosodium glutamate waste liquid used in this example is taken from a certain monosodium glutamate factory in Guangdong Province, and can also use the monosodium glutamate waste liquid from other monosodium glutamate factories. Mixtures in any proportion.

[0077] (1) Uniformly disperse the retrieved fresh papermaking sludge;

[0078] (2) take by weighing fresh monosodium glutamate waste liquid according to monosodium glutamate waste liquid: papermaking sludge=3: 100 (w / w, in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com