Garbage storage pit heating method

A heating method and storage pit technology, which is applied in the direction of combustion method, lighting and heating equipment, combustion type, etc., can solve the problems of unstable combustion of incinerators, high water content of waste entering the furnace, difficulty in fermentation of waste, etc., and achieve favorable reduction chemical, promote garbage fermentation, and have good environmental protection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

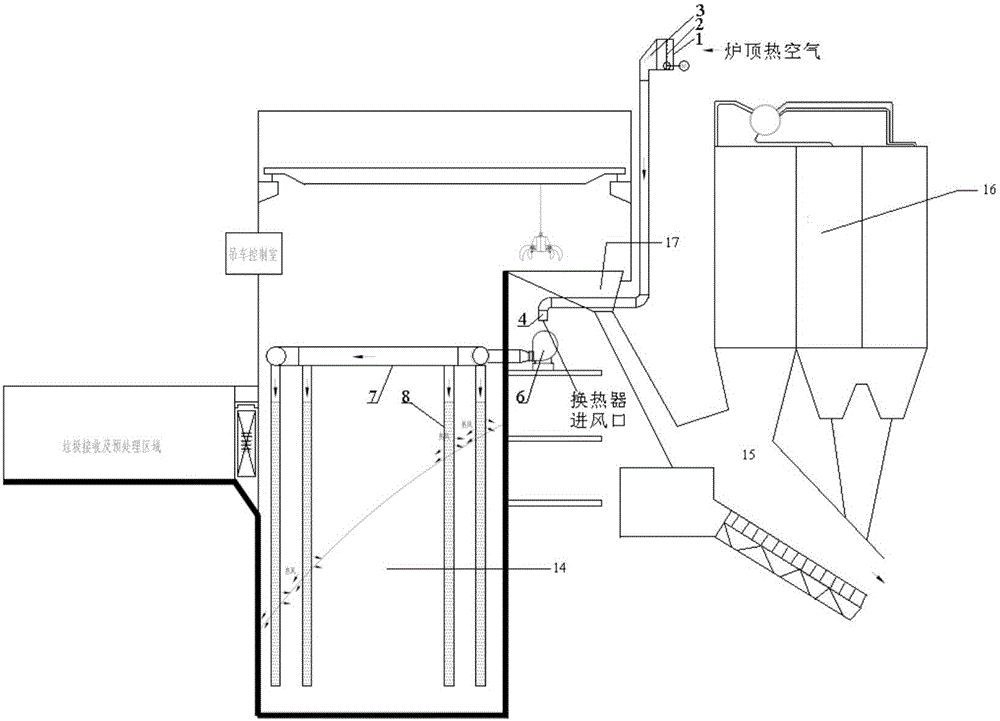

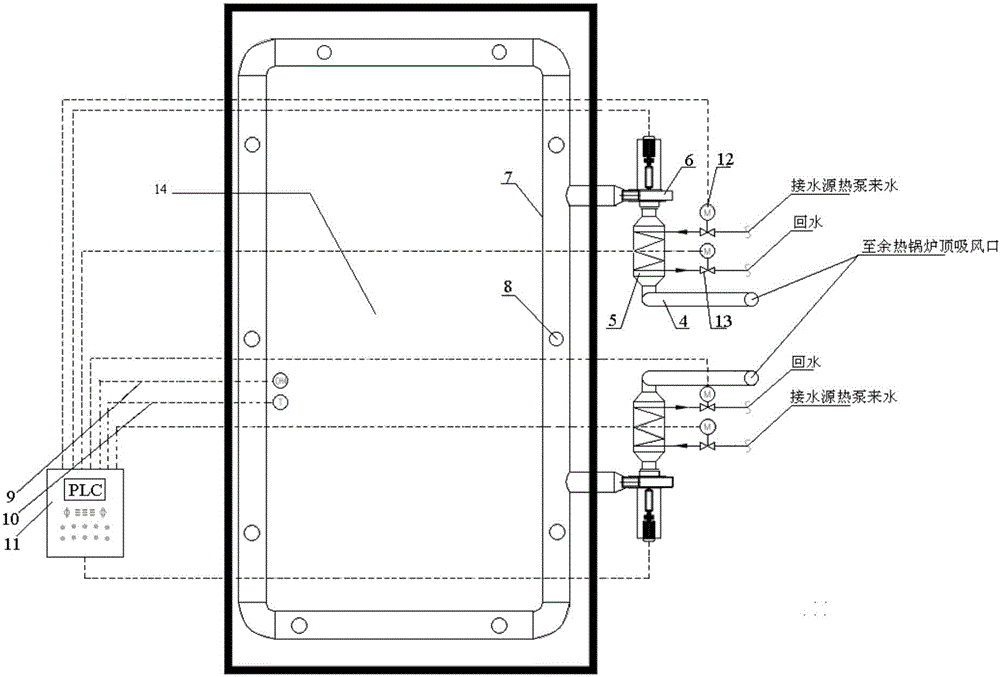

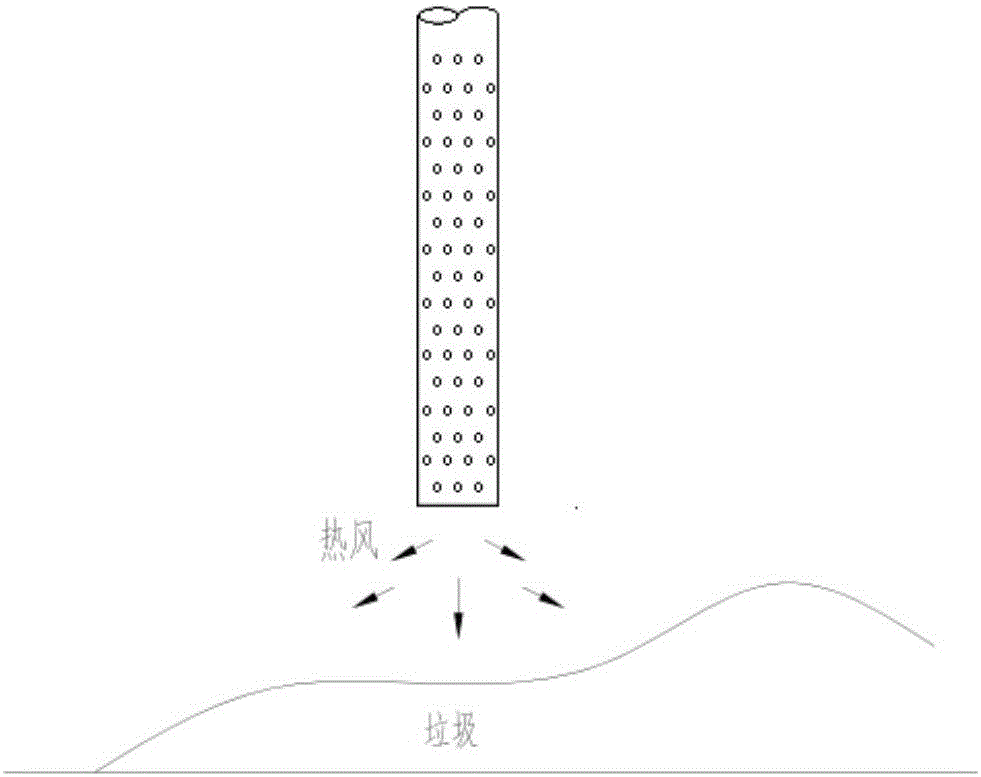

[0022] Such as figure 1 , 2 , 3, a kind of garbage fermentation system includes: garbage storage pit 14, garbage receiving and pretreatment area, crane control room, crane, hopper 17, incinerator 15, the crane control room controls the crane, and the garbage that has been fermented is sent into Incinerate in the incinerator, and set a waste heat boiler 16 above the incinerator to recover waste heat. In order to promote the fermentation of garbage in the garbage storage pit, a garbage storage pit heating device is provided to heat the garbage in the garbage storage pit, and a detection and control device is provided to control the temperature of garbage fermentation.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com