Method of detoxifying asbestos-containing solid waste

A solid waste and waste technology, applied in the field of harmless treatment, can solve problems such as difficulty in securing a new final disposal site, deterioration of processing equipment, and huge size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

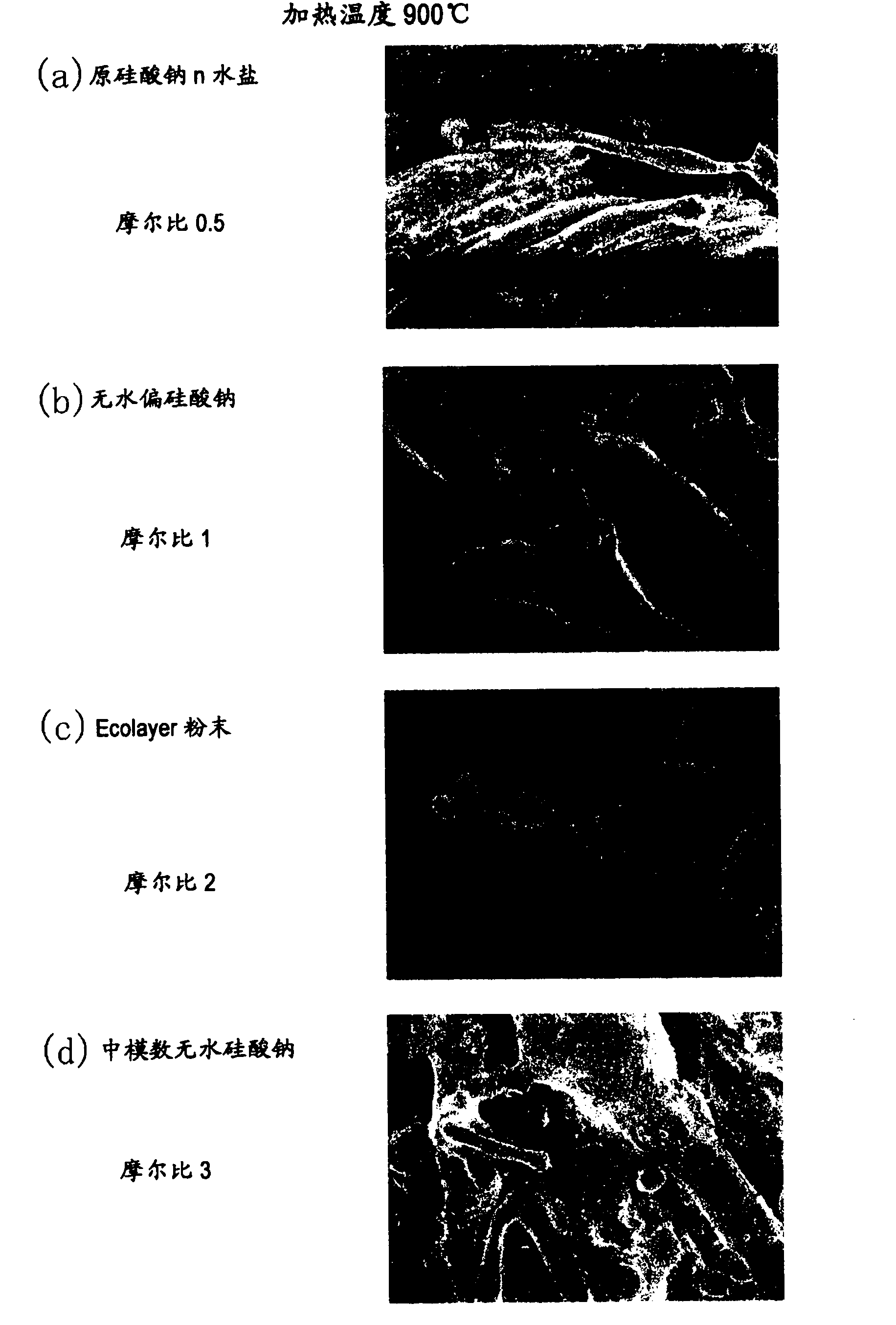

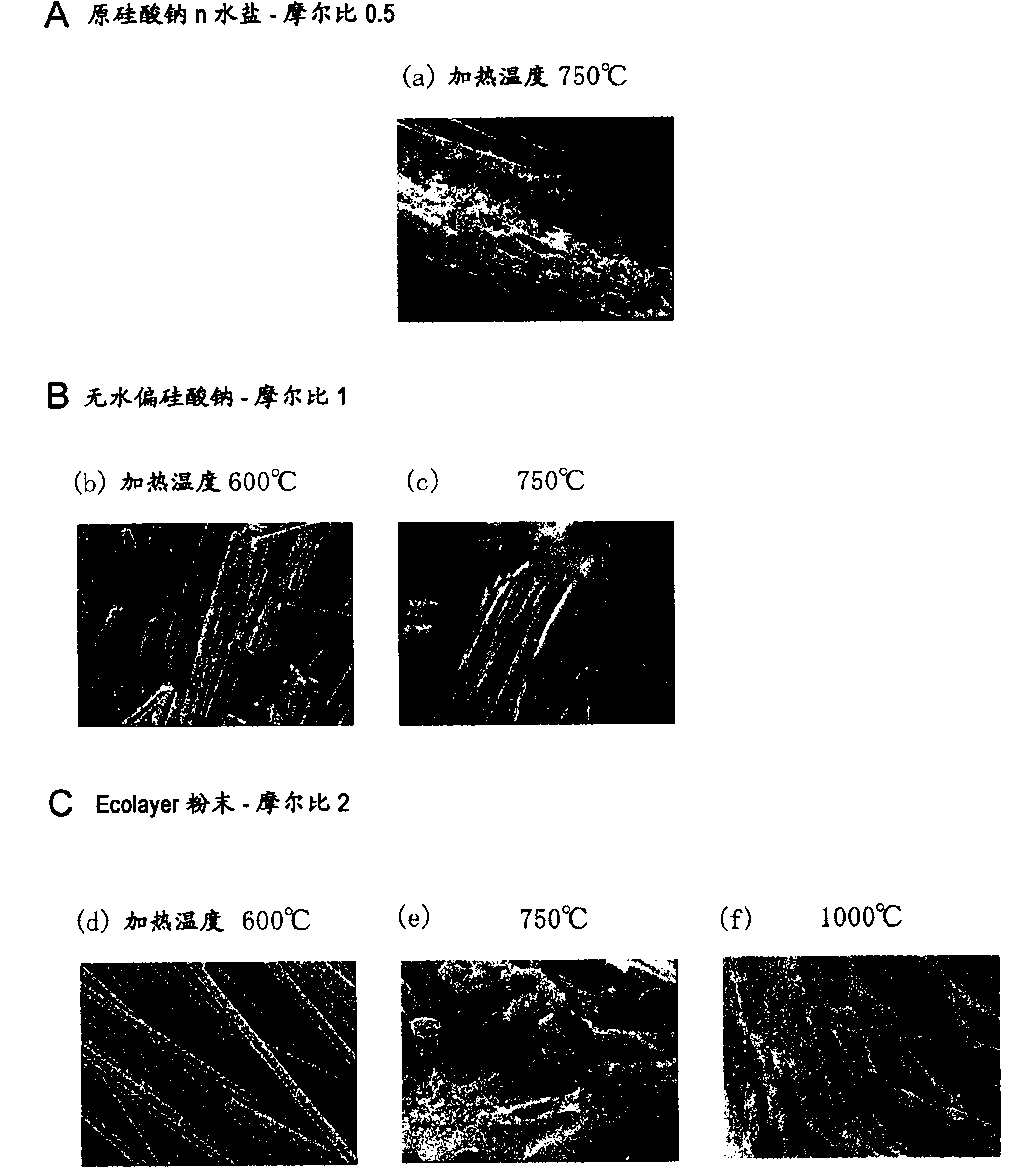

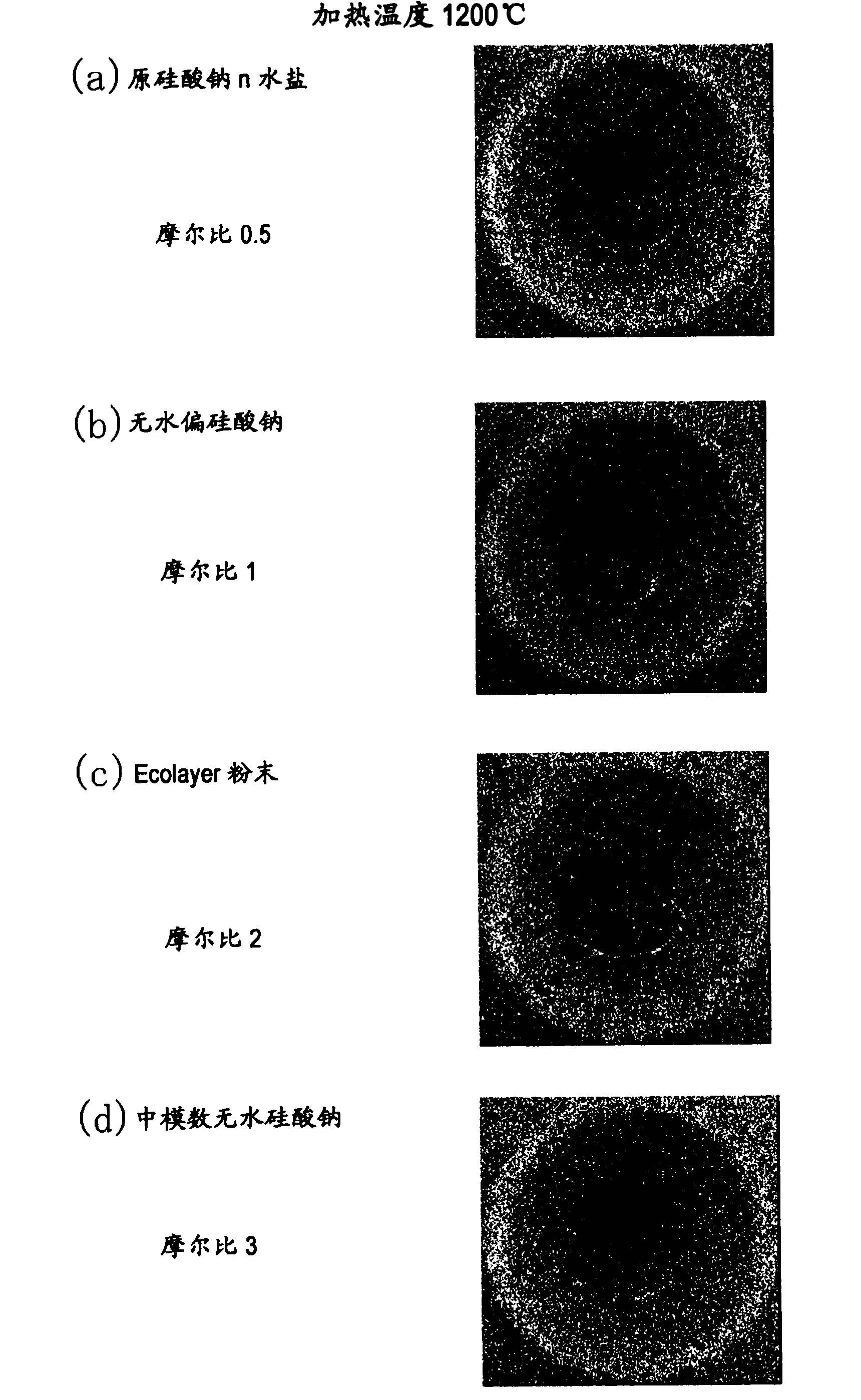

[0108] Mix 0.5g asbestos thread and 0.5g sodium orthosilicate n water salt (SiO 2 / M 2 The molar ratio of O=0.5) was loaded into a crucible with a capacity of 50 ml, and stirred for about 10 seconds using a spatula. Then, the crucible was capped and placed in an electric heating furnace (electric furnace KBF-894N manufactured by Koyo Lindbergh Co., Ltd.), and heated at 900° C. for 1 hour in the electric furnace. Then, it was allowed to cool to room temperature, and the contents were taken out for observation with a scanning electron microscope.

[0109] As a result, asbestos loses its needle-like fibrous structure ( figure 1 -(a)).

Embodiment 2

[0111] Use 0.5g of anhydrous sodium metasilicate (SiO 2 / M 2 The same operation as in Example 1 was performed except that the molar ratio of O = 1) was used as sodium silicate.

[0112] Using a scanning electron microscope to observe the contents of the crucible after heat treatment, asbestos lost its needle-like fiber structure ( figure 1 -(b)).

Embodiment 3

[0114] Use 0.5g Ecolayer powder (SiO 2 / M 2 The same operation as in Example 1 was performed except that the molar ratio of O = 2) was used as sodium silicate.

[0115] Using a scanning electron microscope to observe the contents of the crucible after heat treatment, asbestos lost its needle-like fiber structure ( figure 1 -(c)).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com