Method of detoxifying asbestos-containing solid waste

A technology for solid waste and waste, applied in the field of harmless treatment, which can solve the problems of high cost, fuel cost, and deterioration of treatment equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0102] Hereinafter, several Examples, Comparative Examples, and Reference Examples of the present invention including Example 15 are given, and it goes without saying that the present invention is not limited by these Examples and the like, but is defined by the claims of the patent application.

[0103] In addition, in the following Examples etc., the JEOL DATUM Co., Ltd. low-vacuum scanning electron microscope (model number: JSM-5600LV) was used as a scanning electron microscope. In addition, in each Example, the sodium silicate shown in Table 1 below was used as a solid alkali metal silicate.

[0104] [Table 1]

[0105] Table 1

[0106]

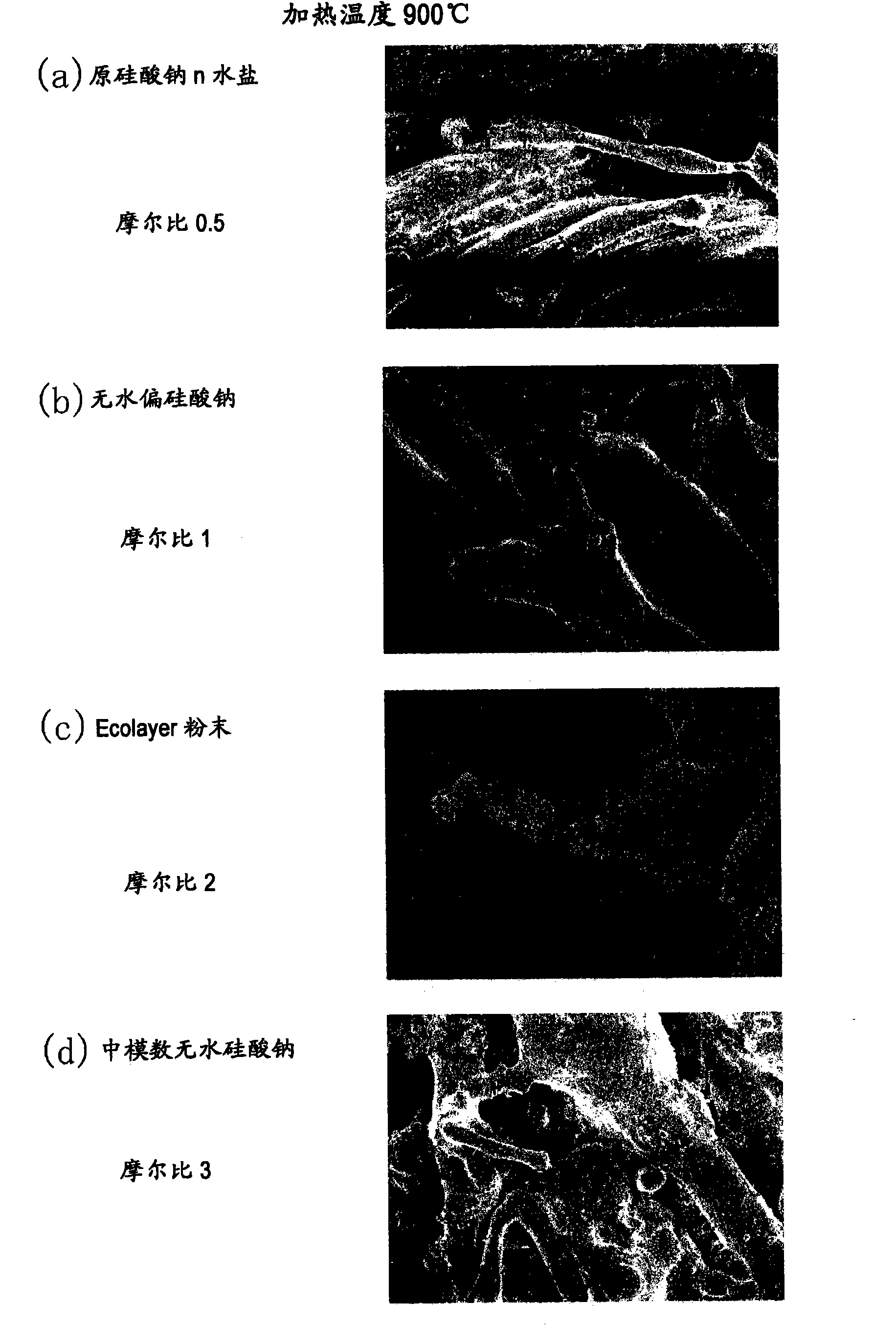

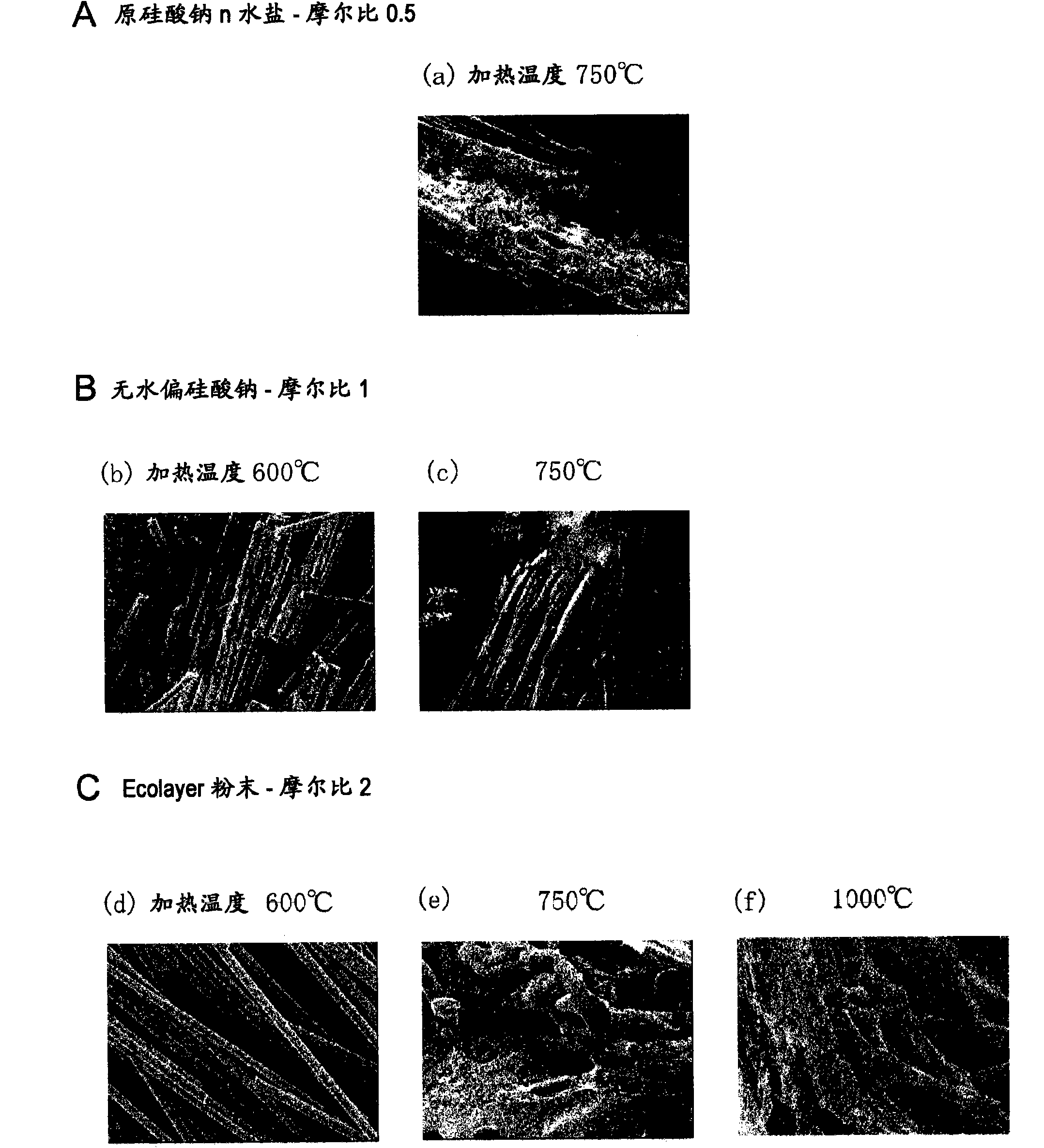

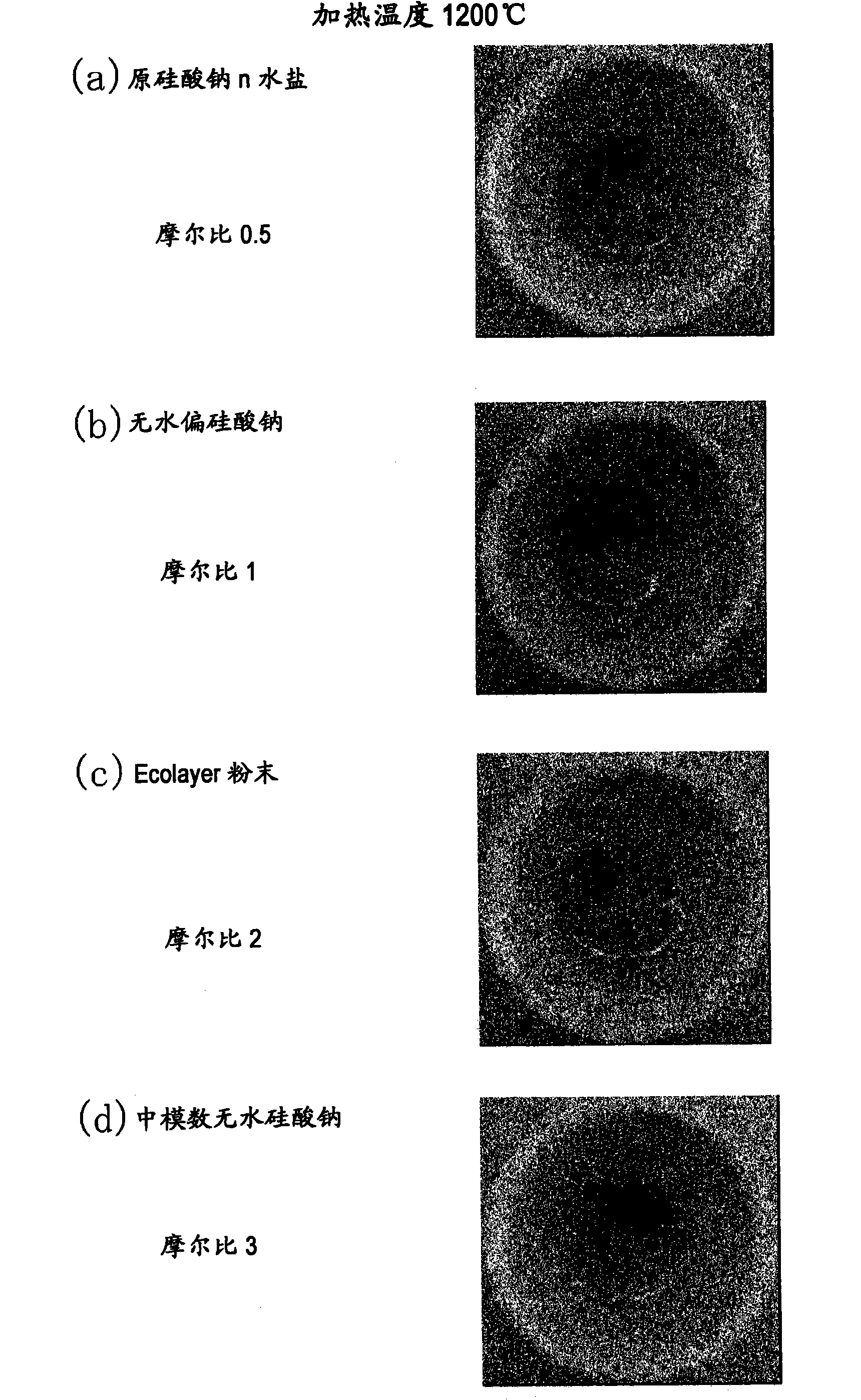

[0107] Reference example A

[0108] Mix 0.5g asbestos thread and 0.5g sodium orthosilicate n water salt (SiO 2 / M 2 The molar ratio of O=0.5) was loaded into a crucible with a capacity of 50 ml, and stirred for about 10 seconds using a spatula. Then, the crucible was capped and placed in an electric heating furnace (electric furn...

Embodiment 15

[0150] The same operation as Reference Example A was performed except that 0.5 g of powdered sodium silicate JIS-1 (a powder obtained by drying water glass and having a water content of 20% by weight) was used as sodium silicate.

[0151] Using a scanning electron microscope to observe the contents of the crucible after heat treatment, as a result, the asbestos lost its needle-like fiber structure, and the asbestos fibers melted during the heat treatment, resulting in a structure of fusion between fibers ( Figure 5 -A(b)).

Embodiment 16

[0153] The same operation as Reference Example A was performed except having used 0.5 g of sodium metasilicate 9 hydrates (water content 57 weight%) as sodium silicate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com