Aluminum electrolysis waste cathode harmless and recycling treatment method and system

A technology of aluminum electrolysis waste cathode and treatment system, which is applied in the field of aluminum electrolysis, can solve the problems of secondary pollution, high cost of equipment relocation, no harmless electrolytic aluminum waste tank lining, resource disposal technology, etc., and achieve improvement Harmless, no secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

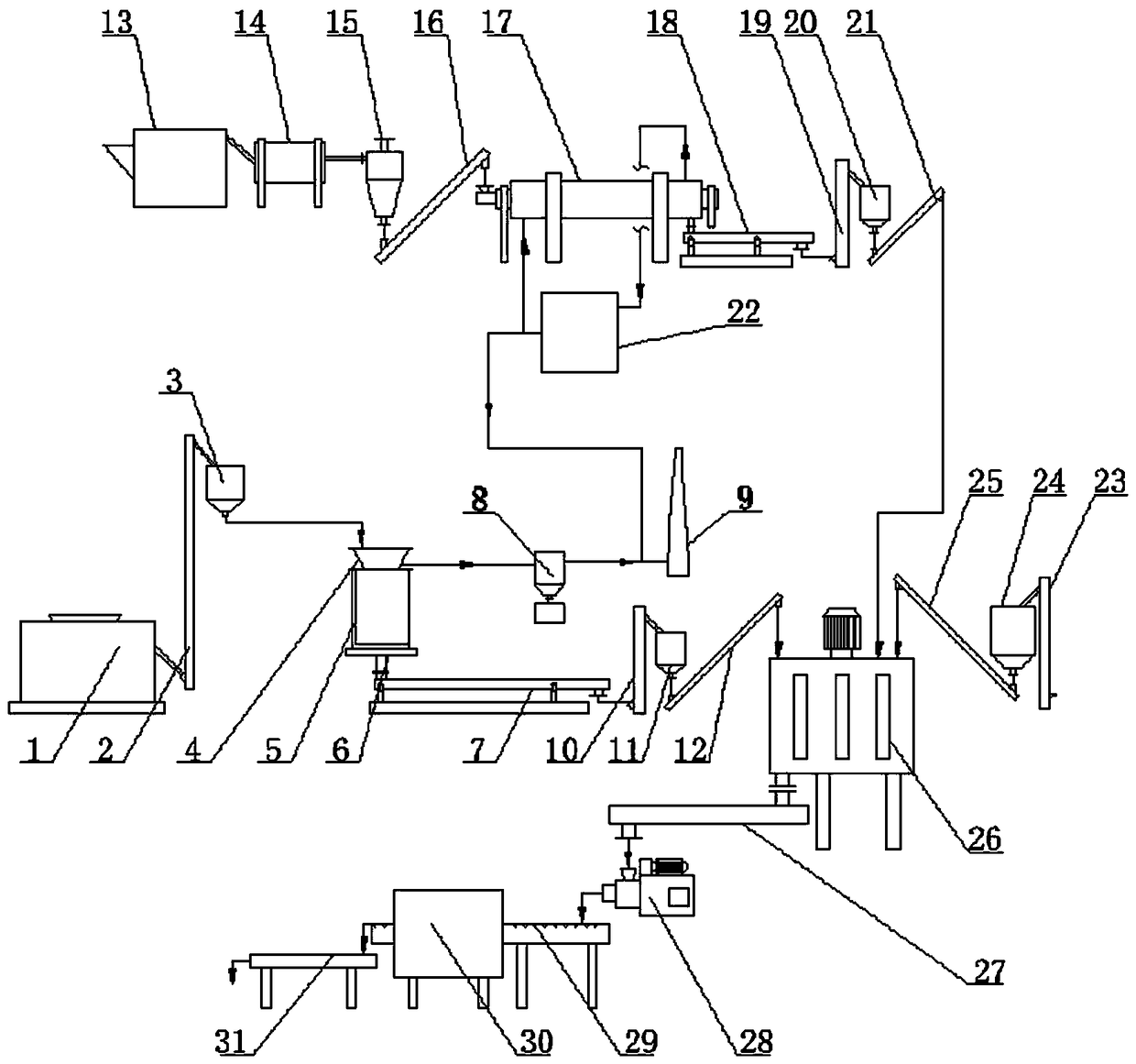

[0032] The invention discloses a method for harmless and resourceful treatment of waste cathodes of aluminum electrolysis. The waste cathodes are put into the first crushing equipment 1 for crushing, crushed to carbon block particles with a particle size ≤ 10mm, and the crushed carbon block particles are transported to high-temperature treatment. 5 in the equipment is heated to 1500°C, held for 60 minutes and then cooled to room temperature to obtain the first carbon material; the biomass waste is crushed into biomass particles with a particle size of ≤10mm, and the biomass particles are transported to the first drying equipment for drying , after being dried until the water content is less than 10%, the dried material is conveyed into the high-temperature carbonization equipment 17 and heated to 800°C, kept for 60 minutes and then cooled to normal temperature to obtain the second carbon material; the first carbon material, the second carbon material The biomass adhesive is add...

Embodiment 2

[0036] The invention discloses a method for harmless and resourceful treatment of waste cathodes of aluminum electrolysis. The waste cathodes are put into the first crushing equipment 1 for crushing, crushed to carbon block particles with a particle size ≤ 10mm, and the crushed carbon block particles are transported to high-temperature treatment. In equipment 5, heat to 2600°C, keep it warm for 30 minutes, and then cool to room temperature to obtain the first carbon material; crush the biomass waste into biomass particles with a particle size of ≤10mm, and transport the biomass particles to the first drying equipment for drying , after being dried until the water content is less than 10%, the dried material is transported into the high-temperature carbonization equipment 17 and heated to 1000°C, kept for 40 minutes and then cooled to normal temperature to obtain the second carbon material; the first carbon material, the second carbon material The biomass adhesive is added to th...

Embodiment 3

[0040] The invention discloses a method for harmless and resourceful treatment of waste cathodes of aluminum electrolysis. The waste cathodes are put into the first crushing equipment 1 for crushing, crushed to carbon block particles with a particle size ≤ 10mm, and the crushed carbon block particles are transported to high-temperature treatment. 5 in the equipment is heated to 2000°C, kept for 45 minutes and then cooled to room temperature to obtain the first carbon material; the biomass waste is crushed into biomass particles with a particle size of ≤10mm, and the biomass particles are transported to the first drying equipment for drying , after being dried until the water content is less than 10%, the dried material is conveyed into the high-temperature carbonization equipment 17 and heated to 900° C., kept for 60 minutes and then cooled to normal temperature to obtain the second carbon material; the first carbon material, the second carbon material The biomass adhesive is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| volatile matter | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com