Method for cutting SiC monocrystal with size being six inches or larger through diamond wire and diamond mortar at same time

A technology of diamond wire and diamond sand, which is used in metal processing equipment, stone processing equipment, fine working devices, etc., can solve the problem that the contact area between diamond wire and SiC single crystal becomes larger, which is not conducive to large-scale cutting of SiC crystal and SiC single crystal. In order to reduce the cutting cost, improve the cutting efficiency, and reduce the total thickness variation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

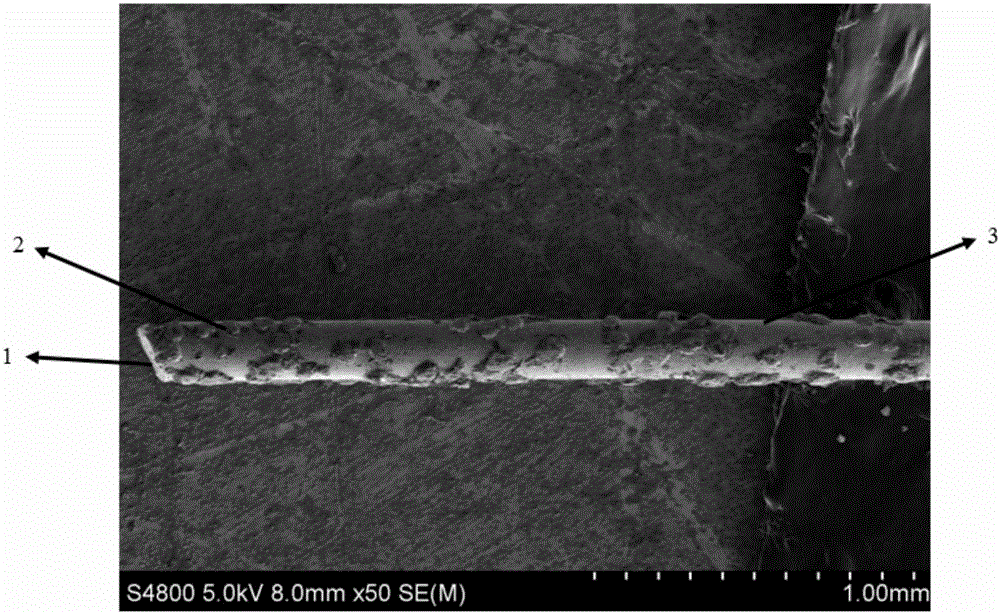

[0039] A method for simultaneously cutting a SiC single crystal of 6 inches or more by using a diamond wire and a diamond mortar, comprising: cutting the SiC single crystal by using a diamond wire soaked in a diamond mortar.

Embodiment 2

[0041] A method for simultaneously cutting a 6-inch SiC single crystal using a diamond wire and a diamond mortar as described in Example 1, comprising the following specific steps:

[0042] (1) Diamond mortar preparation: diamond powder and cutting fluid are mixed into diamond mortar; wherein, the diamond powder is diamond abrasive grains;

[0043] (2) winding the diamond wire on a multi-wire cutting machine to form a diamond wire mesh;

[0044] (3) Place the SiC single crystal: place the SiC single crystal to be cut on the workbench and fix it, move and adjust the workbench so that the top of the SiC single crystal is in contact with the diamond wire mesh;

[0045] (4) Crystal cutting: start the multi-wire cutting machine, and spray the diamond mortar to the diamond wire, so that the diamond wire soaked in the diamond mortar cuts the SiC single crystal into wafers of the target size. The present invention can set the appropriate diamond mortar flow rate according to the numb...

Embodiment 3

[0052] A method for simultaneously cutting a 6-inch SiC single crystal using diamond wire and diamond mortar as described in Example 2, the difference is:

[0053] The diameter of the diamond wire is 230 μm.

[0054] The feed speed of the multi-wire cutting machine is 0.033mm / min. The cutting time is about 75.86h.

[0055] In step (1), the mass percentage of diamond abrasive grains in the diamond mortar is 30%, and the diameter of the diamond abrasive grains is 5 μm;

[0056] In the step (4), the tension of the diamond wire during the cutting process is set to 40N. The wire feeding speed of the diamond wire is 45m / min. The flow rate of diamond mortar sprayed to the diamond wire is 90L / min.

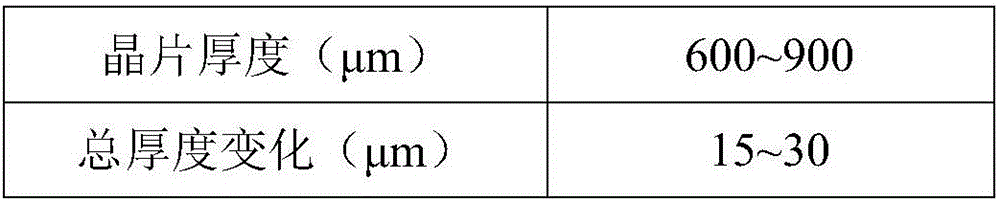

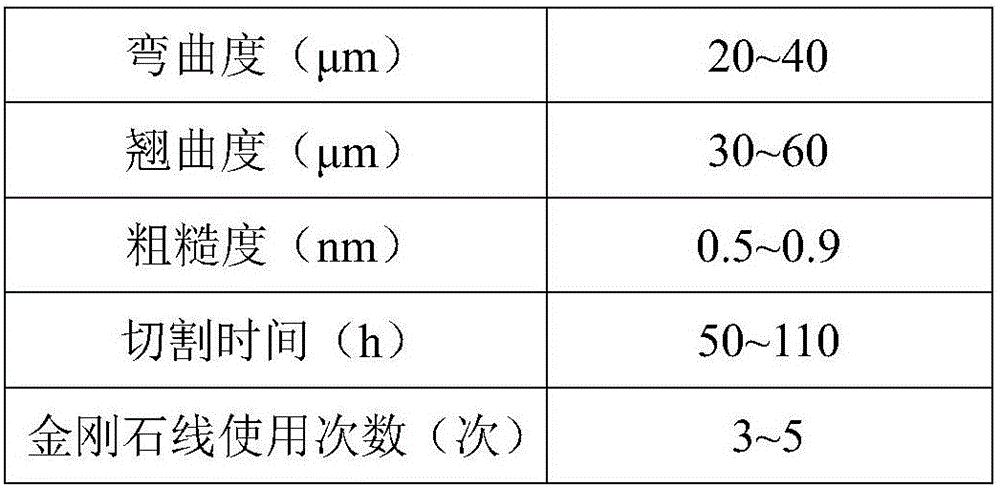

[0057] Remove the wafer cut to the target size from the workbench, and measure its quality with relevant equipment: the thickness of the wafer is 690 μm, the total thickness variation is 20 μm, the curvature is 22 μm, the warpage is 30 μm, and the roughness is 0.6nm .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com