Lithium ion battery negative electrode, preparation method and application thereof

A lithium-ion battery and negative electrode technology, applied in the field of lithium-ion battery negative electrode and its preparation, can solve the problems of decreased cycle stability, reduced electrical contact, active material shedding, etc., to improve structural stability and electrochemical stability, improve The effect of efficient transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The specific preparation method of above-mentioned negative electrode of lithium ion battery and lithium ion button battery comprises the following steps:

[0037] Step 1, mix the negative electrode active material, conductive agent and base binder solution, ball mill in a planetary ball mill for 1 hour to obtain a uniformly mixed slurry, and use an automatic film coating machine to evenly coat the above slurry on the copper foil current collector, The coating thickness is 25 μm or 50 μm, and the initial electrode is obtained after vacuum drying at 60°C; the coating polymer solution is quantitatively coated on the surface of the initial electrode, and after vacuum drying at 120°C for 2 hours, a double-layer adhesive-wrapped negative electrode is obtained The negative electrode of the structure of active material; Wherein, the mass ratio of negative electrode active material, conductive agent and binding agent total amount is: (70~95): (15~4): (15~1); The mass ratio of l...

Embodiment 1

[0051] Use the method designed in the present invention to prepare the nano-silicon negative electrode of lithium ion battery, wherein the mass ratio of base binder and coating polymer is (1:1);

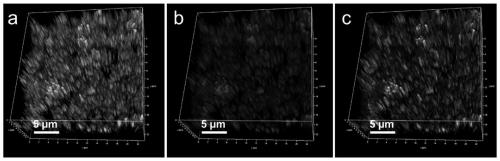

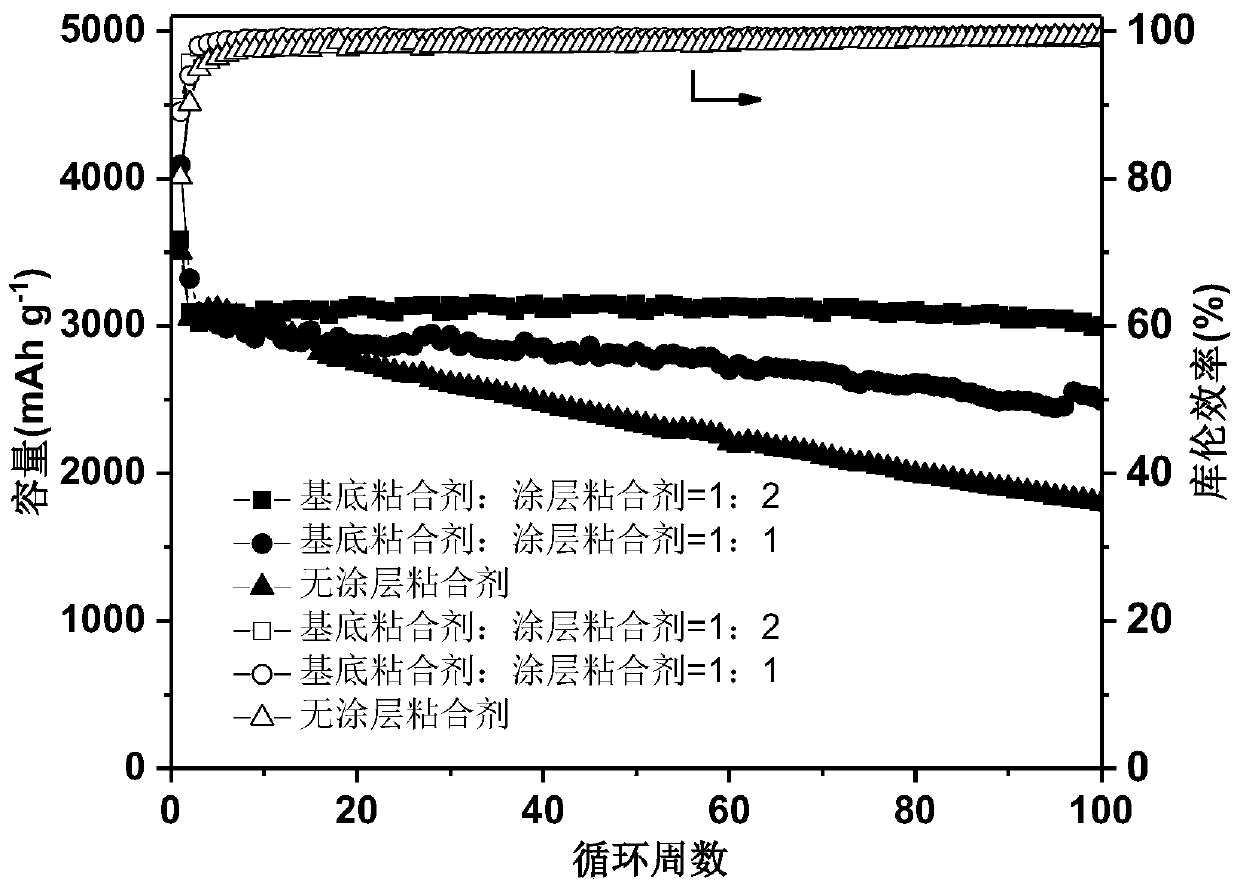

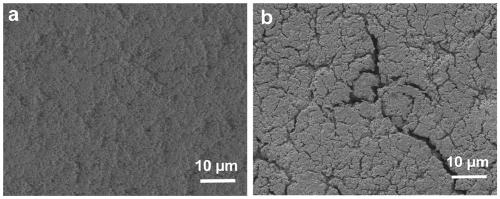

[0052] Nano-silicon particles and Super-P conductive carbon black were dispersed into the base binder polyacrylic acid (PAA) aqueous solution, and ball milled in a planetary ball mill for 1 h to make them fully mixed to obtain a uniformly mixed negative electrode slurry. An automatic coating machine was used to coat the slurry on a copper foil current collector with a coating thickness of 25 μm, and dried at 60° C. to remove moisture to obtain an initial electrode. Then, the coating polymer ion-conducting polyurethane (B1) was quantitatively coated on the surface of the initial electrode, and dried at 120° C. for 2 hours to obtain the final electrode. The mass ratio of nano-silicon, conductive carbon black, base binder and coating polymer is 70:15:7.5:7.5. The above electrode was cu...

Embodiment 2

[0057] Use the method designed in the present invention to prepare the nano-silicon negative electrode of lithium ion battery, wherein the mass ratio of base binder and coating polymer is (1:2);

[0058] Nano-silicon particles and Super-P conductive carbon black were dispersed into the base binder polyacrylic acid (PAA) aqueous solution, and ball milled in a planetary ball mill for 1 h to make them fully mixed to obtain a uniformly mixed negative electrode slurry. An automatic coating machine was used to coat the slurry on a copper foil current collector with a coating thickness of 25 μm, and dried at 60° C. to remove moisture to obtain an initial electrode. Then, the coating polymer ion-conducting polyurethane (B1) was quantitatively coated on the surface of the initial electrode, and dried at 120° C. for 2 h to obtain the final electrode. The mass ratio of nano-silicon, conductive carbon black, base binder and coating polymer is 70:15:5:10. The above electrode was cut into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com