NiAl-TiB2-TiC-Al2O3 porous membrane and its synthetic method with plasma heating reaction

A technology of nial-tib2-tic-al2o3 and a synthesis method, which is applied in the field of porous materials and their preparation, can solve the problems of high thin-sheet porous membrane structure, difficult strength, unfavorable preparation of catalyst coatings, etc. The effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

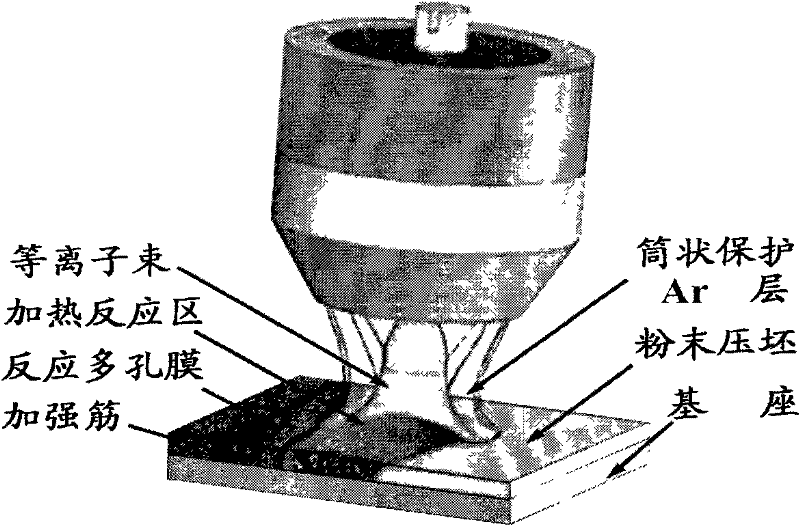

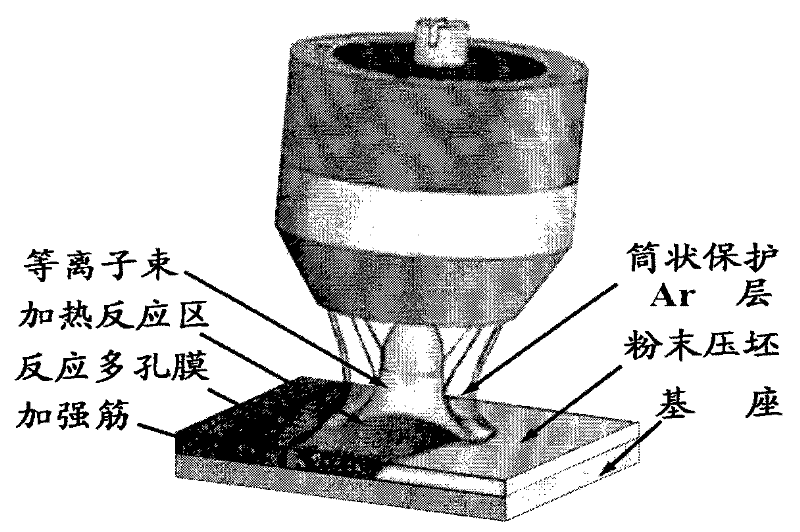

Image

Examples

Embodiment 1

[0041] The NiAl-TiB of this embodiment 2 -TiC-Al 2 o 3 Porous membranes were prepared by the following methods:

[0042] Step 1: Powder Preparation

[0043] Take commercially available titanium (Ti) powder, boron carbide (B 4 C) powder, boron trioxide (B 2 o 3 ) powder, nickel (Ni) powder and aluminum (Al) powder, requiring boron carbide (B 4 C), boron trioxide (B 2 o 3 ) and nickel (Ni) powder particle size is 200 mesh, titanium (Ti) powder and aluminum (Al) powder particle size is 100 mesh;

[0044] Step 2: Reaction Material Configuration and Mixing

[0045] The above Ni powder, Al powder, Ti powder, B 4 C and B 2 o 3 powder, according to the molar ratio Ni:Al:Ti:B 4 C:B 2 o 3 = 1: 3: 4: 1: 1, and use a three-dimensional mixer to dry mix for 6 to 8 hours to obtain a uniformly mixed powder;

[0046] The third step: billet

[0047] Put the uniformly mixed powder into a steel mold and cold-press it into a round compact with a size of 50×50×3mm and a compaction ...

Embodiment 2

[0057] The difference from Example 1 is that the gas volume of the plasma beam is 0.5m 3 / h, current 55A, scanning speed 8mm / s The main process parameters and related performance of the sample are shown in Table 2.

[0058] Table 2

[0059] Compact thickness (mm)

Embodiment 3

[0061] The difference from Example 2 is that the gas volume of the plasma beam is 0.6m 3 / h, current 60A, scanning speed 10mm / s The main process parameters and related performance of the sample are shown in Table 3.

[0062] table 3

[0063] Compact thickness (mm)

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com