Internal combustion type rail belt grinder

A grinding machine and rail technology, which is applied to the field of internal combustion type steel rail abrasive belt grinding machines, can solve the problems that it is difficult to meet the requirements of short-time skylight operation, the external size of the grinding wheel grinding machine is large, and the grinding wheel rotation speed cannot be too high, etc., and achieves light weight and compact structure. , Simple effect of grinding adjustment mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

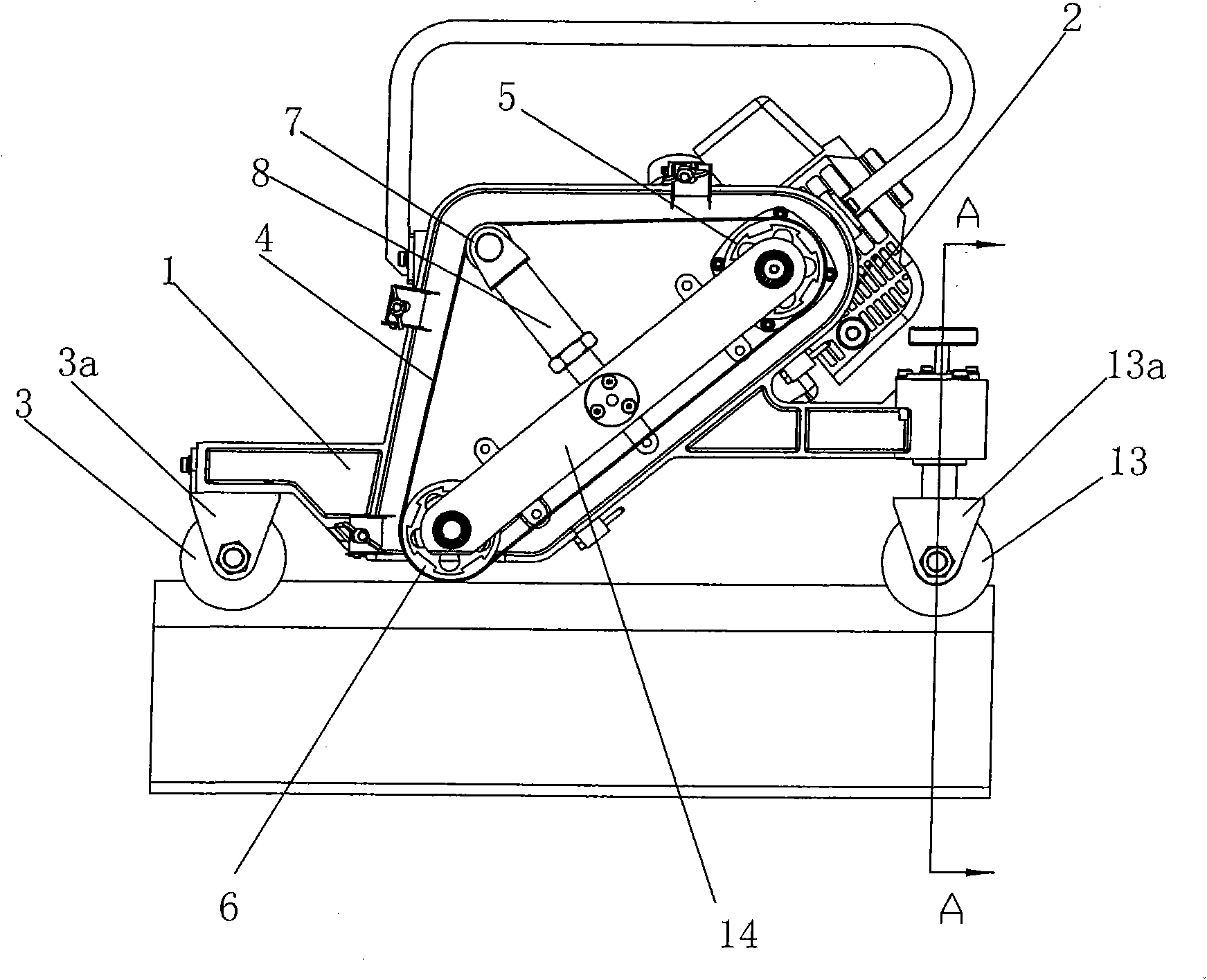

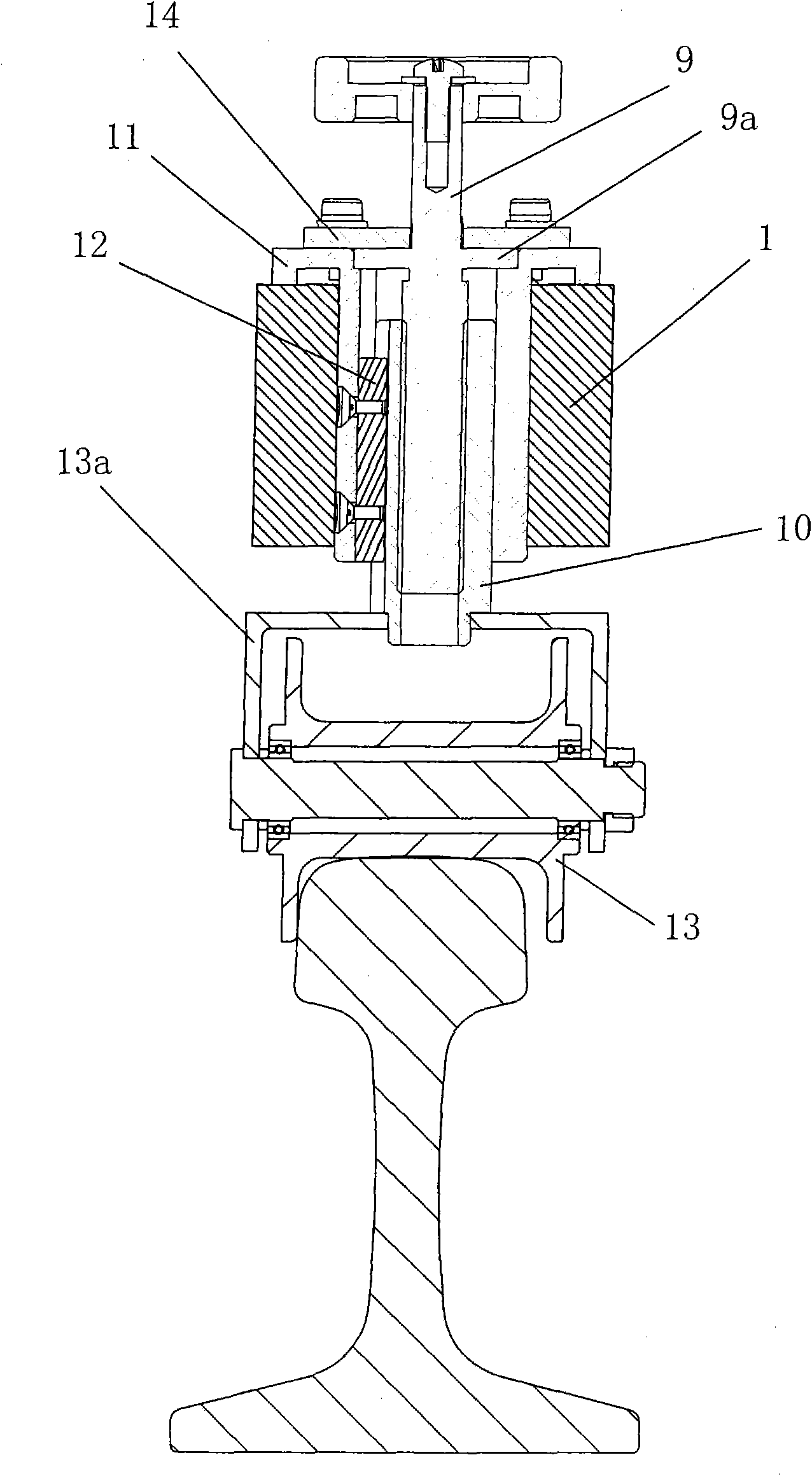

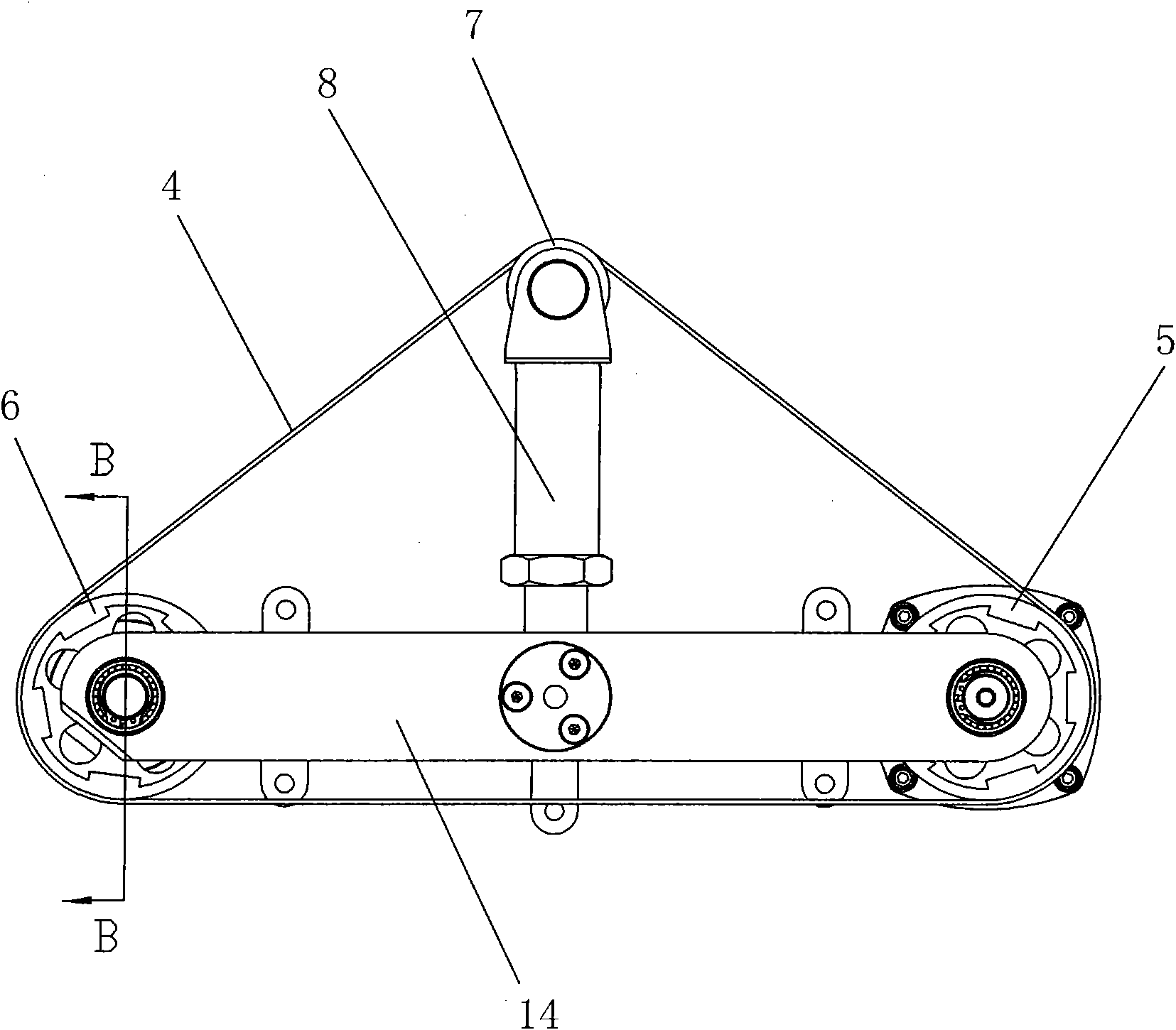

[0015] figure 1 It is a schematic diagram of the overall structure of the internal combustion type rail abrasive belt grinding machine of the present invention; figure 2 for figure 1 Sectional view along A-A; image 3 It is a schematic diagram of the abrasive belt drive structure of the internal combustion type rail abrasive belt grinder of the present invention; Figure 4 for image 3 Sectional view along B-B.

[0016] As shown in the figure, the internal combustion rail abrasive belt grinding machine of the present invention includes a frame 1, an abrasive belt 4, a driving wheel 5, a contact wheel 6, a tensioning wheel 7, a front walking profiling wheel 3 arranged on the frame 1 and Back walking profiling wheel 13 and the internal combustion engine 2 that is arranged on frame 1 and is used to drive drive wheel 5 to rotate, described emery belt 4 is wound on the outer circle of drive wheel 5, contact wheel 6 and tension wheel 7 successively, An adjusting mechanism for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com