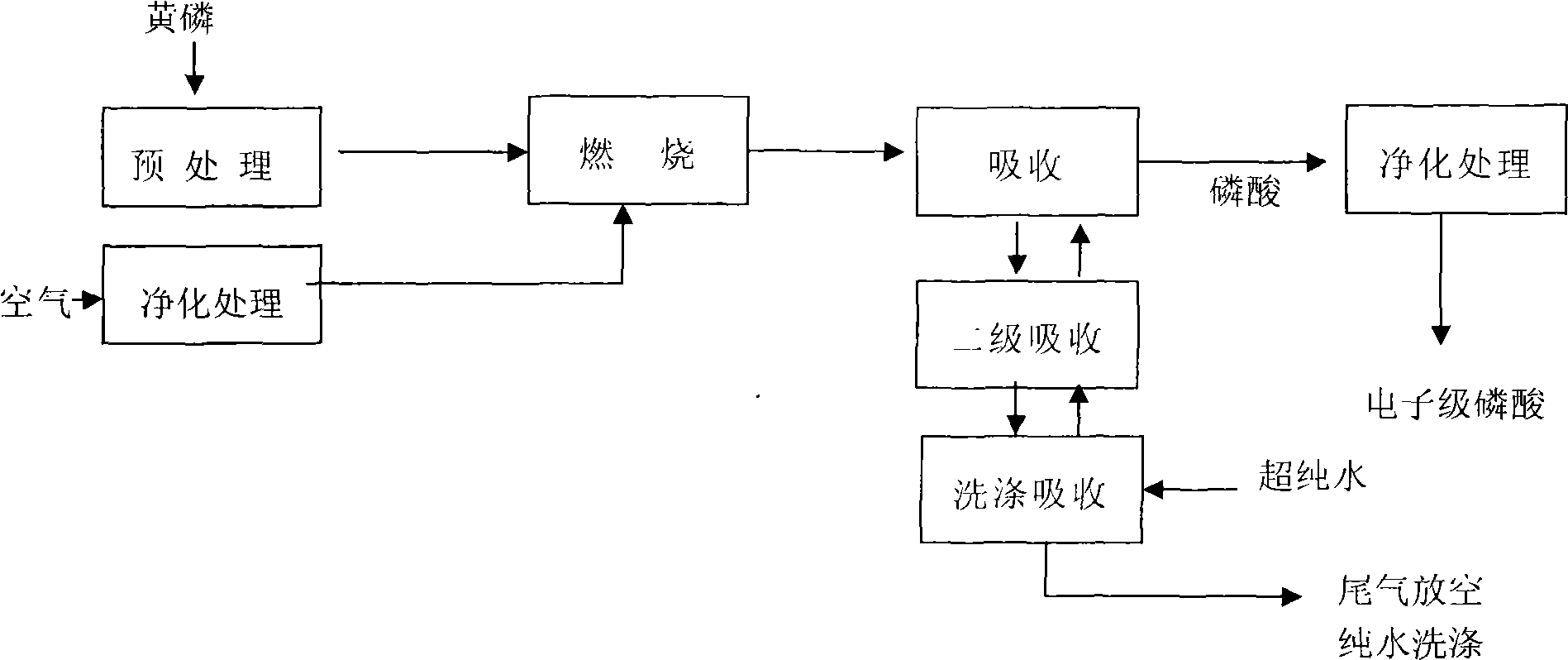

Method for directly preparing electronic grade phosphoric acid by yellow phosphorus

A technology of electronic grade phosphoric acid and yellow phosphorus, which is applied in the direction of phosphoric acid and phosphorus oxyacids, and can solve problems such as low product yield, high raw material requirements, and large equipment loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Rinse 1,200 kg of industrial yellow phosphorus with a purity of 99.93%, which contains 0.0133% arsenic, with ultra-pure water that meets GB / T 11446.1-1997’s first-class water standard for the electronics industry, and the delivery rate of industrial yellow phosphorus is 20-30kg / h Send it into the combustion tower for combustion, and at the same time, degreasing, impurity removal and humidity control are performed on the air entering the tower, and the moisture content of the air is controlled so that the molar ratio of moisture in the tower to phosphorus pentoxide produced by the reaction is 0.728. Under this condition, the P produced after the yellow phosphorus is fully burned 2 o 5 The gas is circulated and absorbed in the absorption tower with ultra-pure water that has reached the first-grade water standard for the electronics industry of GB / T 11446.1-1997. When the concentration of acid produced by absorption reaches 85.0%-87.0%, it is introduced into the acid post...

Embodiment 2

[0024] Rinse 5,000 kg of industrial yellow phosphorus with a purity of 99.96% and containing 0.0098% of arsenic in ultrapure water. The transport volume per hour is sent to the combustion tower for combustion, and the air entering the tower is treated with oil removal, impurity removal and humidity control, and the moisture content of the air is controlled so that the molar ratio of the moisture in the tower to the phosphorus pentoxide produced by the reaction Between 0.029-0.082. The P produced by the complete combustion of yellow phosphorus 2 o 5 The gas is circulated and absorbed in the absorption tower with ultra-pure water that has reached the secondary water standard for the electronics industry of GB / T 11446.1-1997. When the concentration of the acid produced by absorption reaches about 85.4%, it is introduced into the acid post-purification treatment system, and under the condition of 1000-level air purification environment, the anion and cation removal and filtratio...

Embodiment 3

[0026] Send 3,000 kg of industrial yellow phosphorus with a purity of 99.96%, which contains 0.0088% of arsenic, into the yellow phosphorus rinsing device, use ultrapure water for rinsing pretreatment, and then send it to the combustion tower for combustion at a delivery rate of 20-30kg / h. Filter, degrease and control the humidity of the air passing through the combustion tower, so that the molar ratio of water in the tower to the phosphorus pentoxide produced by the reaction is between 0.443-0.772. Under this condition, the yellow phosphorus can be fully burned, will generate P 2 o 5 The gas is passed into the absorption tower, and the ultrapure water is used for circulating absorption. When the concentration of the circulating acid reaches about 85.0%, it is sent to the acid purification treatment system, and the purification treatment of removing anions, cations, filtration, aeration and precision filtration is carried out in a 10,000-level air purification environment, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com