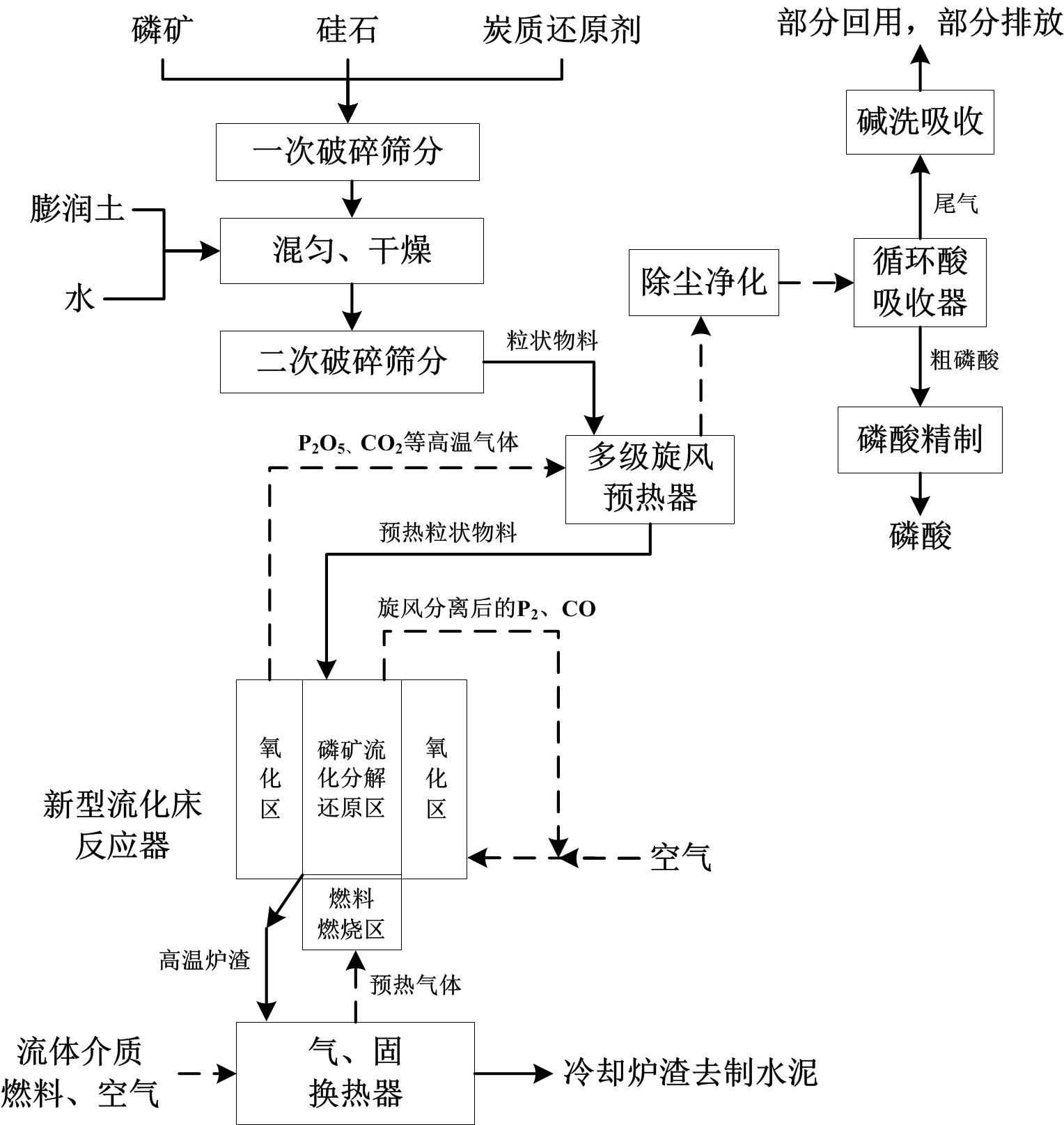

Technique and device for preparing phosphoric acid by fluidized bed reactor

A fluidized bed reactor, phosphoric acid technology, applied in phosphoric acid, phosphorus oxyacid and other directions, can solve the problems of redox zoning, long time required, expensive coating agent, etc., achieve uniform bed temperature, reduce heat supply, The effect of avoiding premature burnout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

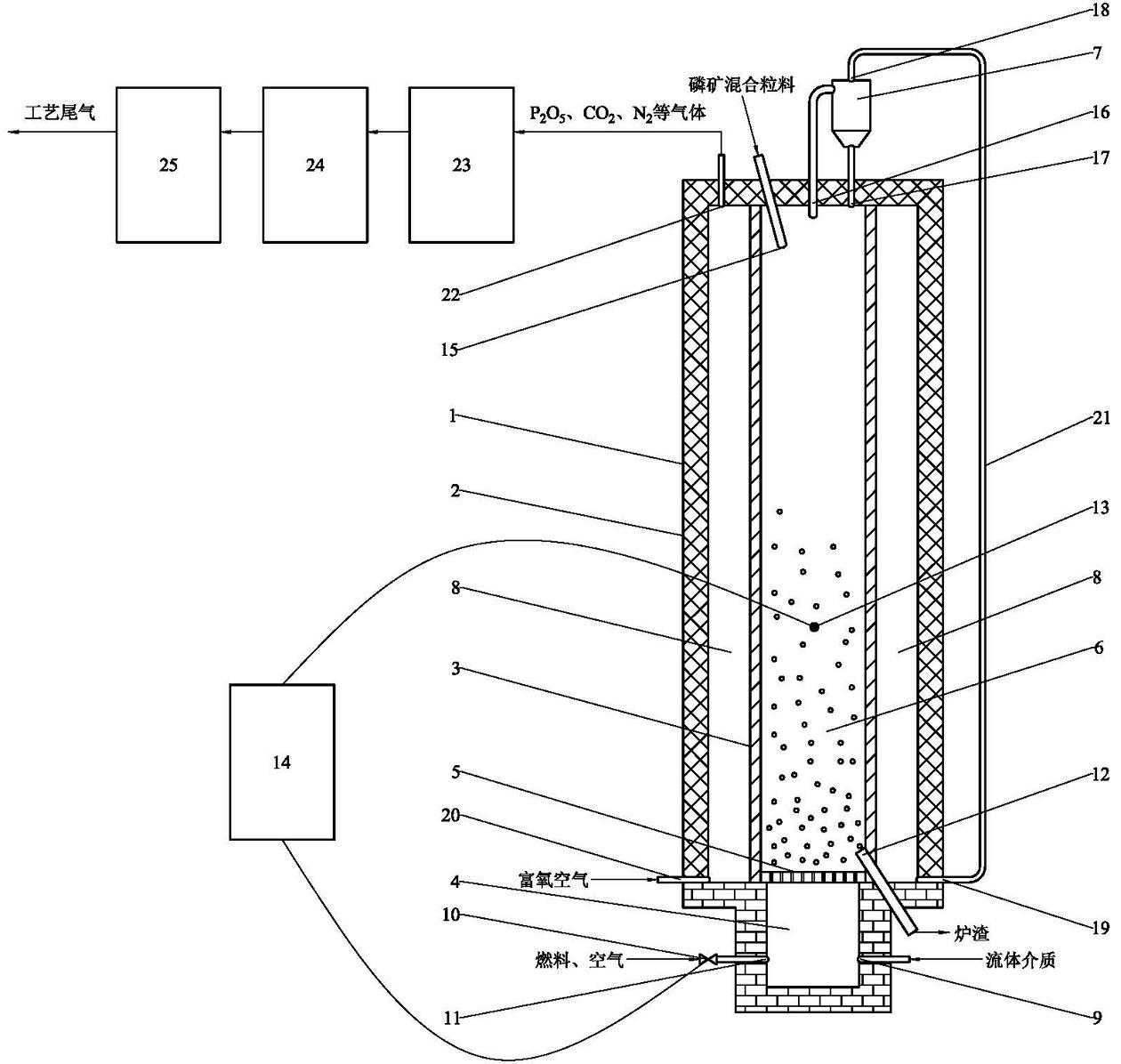

[0037] Such as figure 2 As shown, the fluidized bed reactor for producing phosphoric acid includes an outer shell 2, an inner shell 3, a combustion chamber 4, a cyclone separator 7 and a hydration cycle acid absorption device 24, and the inner diameter of the outer shell 2 and the inner shell 3 The ratio is 1.5:1~3:1, the inner surface of the outer shell 2 and the outer surface of the inner shell 3 form an annular oxidation zone 8; the inner shell 3 is provided with a gas distributor 5 and a fluidized reduction reaction zone 6, The gas distributor 5 adopts a vertical porous plate distributor, wherein the top of the fluidized reduction reaction zone 6 is provided with a phosphate rock mixed particle feed port 15 and a reaction gas product outlet 16 in the reduction zone, and the bottom is near the top of the gas distributor 5. The slag discharge port 12; the bottom of the combustion chamber 4 is provided with fluid medium gas inlet 9, fuel and air inlet and control valve 10 and ...

Embodiment 2

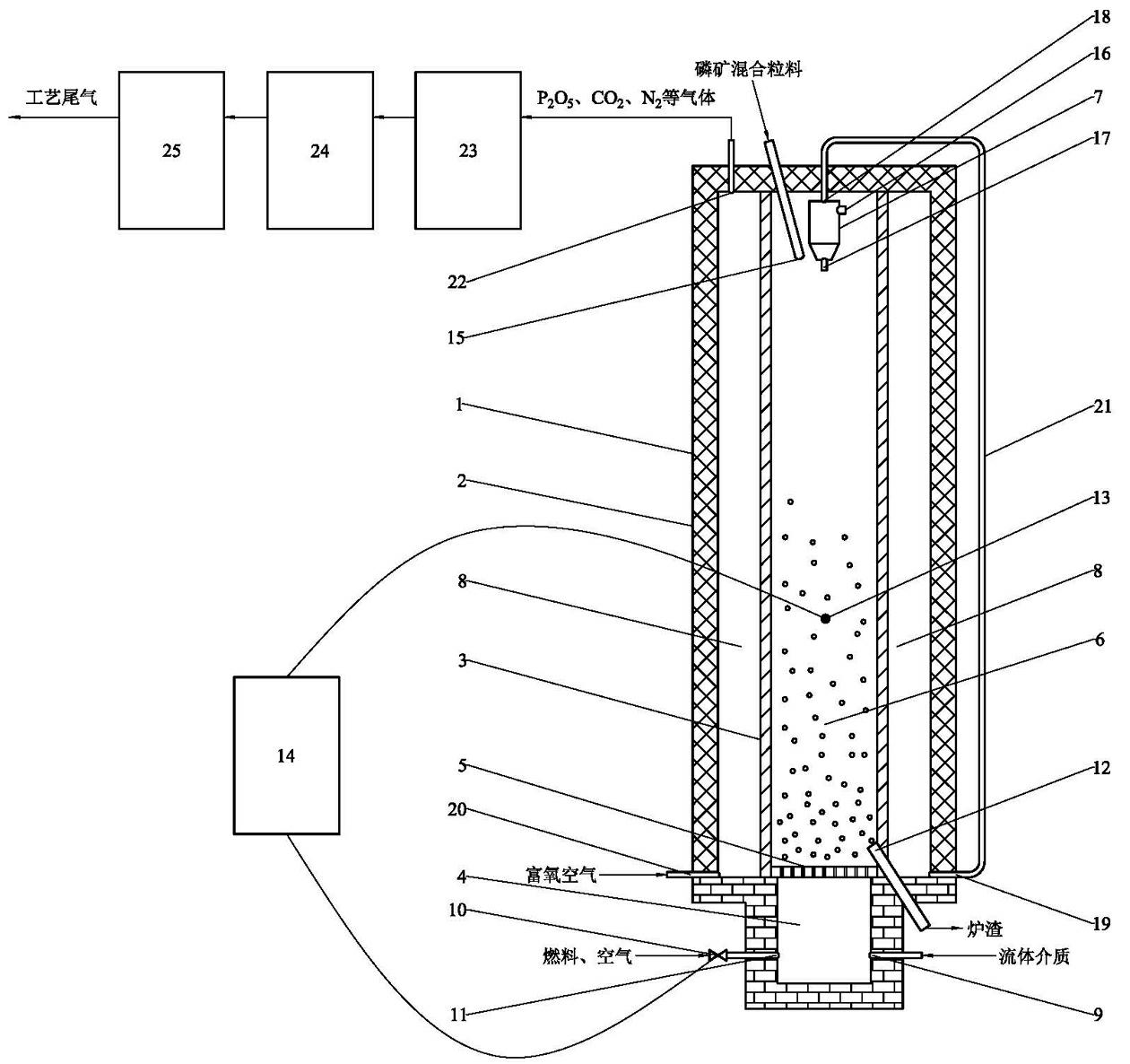

[0040] Such as image 3 As shown, the fluidized bed reactor for producing phosphoric acid includes an outer shell 2, an inner shell 3, a combustion chamber 4, a cyclone separator 7 and a hydration cycle acid absorption device 24, and the inner diameter of the outer shell 2 and the inner shell 3 The ratio is 1.5:1~3:1, the inner surface of the outer shell 2 and the outer surface of the inner shell 3 form an annular oxidation zone 8; the inner shell 3 is provided with a gas distributor 5 and a fluidized reduction reaction zone 6, The gas distributor 5 adopts a spiral porous plate distributor, wherein the top of the fluidized reduction reaction zone 6 is provided with a phosphate rock mixed particle feed port 15 and a reaction gas product outlet 16 in the reduction zone, and the bottom is near the top of the gas distributor 5. The slag discharge port 12; the bottom of the combustion chamber 4 is provided with fluid medium gas inlet 9, fuel and air inlet and control valve 10 and b...

preparation Embodiment 1

[0042] Preparation Example 1 (using Example 1):

[0043] 1) Phosphate rock (24% P 2 o 5 ) 250 parts, 290 parts of silica and 32 parts of coke, crushed and sieved to 100~200 mesh, then added 40 parts of bentonite and mixed evenly, then added 60 parts of water and stirred again, then placed in an oven to dry and dehydrate to water The content is less than 2%, and then through secondary crushing and screening to 90%, passing through 100~150 mesh sieve into granular materials for later use;

[0044] 2) Put the above-mentioned granular material into the fluidized reduction reaction zone 6 in the fluidized bed reactor through the phosphate rock mixed granular material inlet 15 of the fluidized bed reactor cylinder 1, and exchange heat through the high temperature gas generated in the oxidation zone 8 And in the combustion chamber 4 supplementary fuel (natural gas) is burned and heated to raise the temperature, and the temperature is controlled to 1350°C through the external temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com