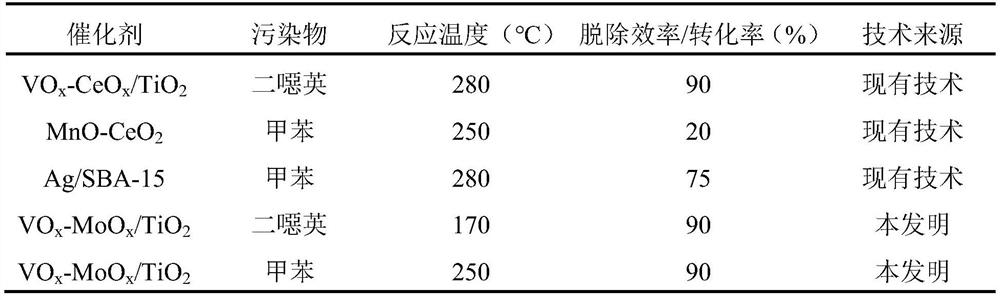

Preparation and application method of VOx-MoOx/TiO2 catalyst for degrading dioxin at low temperature

A catalyst, dioxin technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of general dioxin catalytic efficiency, etc. Catalytic removal efficiency, lowering initial reduction temperature, lowering effect of activation energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0026] VO x -MoO x / TiO 2 The preparation method of powder catalyst:

[0027] (1) Dissolve ammonium metavanadate in ethanolamine to obtain ammonium metavanadate solution, and dissolve ammonium molybdate tetrahydrate in deionized water to obtain ammonium molybdate solution; when preparing the solution, use a 50°C water bath to heat it, and use a magnetic Stir well to promote dissolution; then mix the two to make a precursor solution;

[0028] (2) Combine the precursor solution with nano-TiO 2 The carrier is mixed and stirred to obtain a viscous paste; after the paste is left to stand for 36 hours, it is dried at 105°C for 24 hours; the mass ratio of each raw material component is, nano-TiO 2 : Ammonium metavanadate: Ammonium molybdate tetrahydrate = 6: 0.429: 0.409.

[0029] (3) The dried block material was crushed and passed through a 60-mesh screen, and calcined at 450°C for 3 hours in an air atmosphere to obtain VO x -MoO x / TiO 2 Powder catalyst; during calcination,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com