Substrate treating apparatus

a technology of substrate and treating apparatus, which is applied in the direction of phosphorus oxyacids, instruments, inorganic non-surface active detergent compositions, etc., can solve the problems of silicon and other substances deposited in the phosphoric acid, the temperature of the phosphoric acid aqueous solution extracted from the circulating line is lower than in the conventional technique, and the concentration measurement device cannot be provided on the circulating line as in the conventional techniqu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

[0046]Embodiment 1 of this invention will be described hereinafter with reference to a drawing.

[0047]Embodiment 1 will be described taking, as an example, an apparatus for immersing substrates (e.g. semiconductor wafers) having silicon oxide film and silicon nitride film formed thereon in a phosphoric acid aqueous solution produced by mixing phosphoric acid and deionized water, to carry out etching treatment for selectively etching the silicon nitride film.

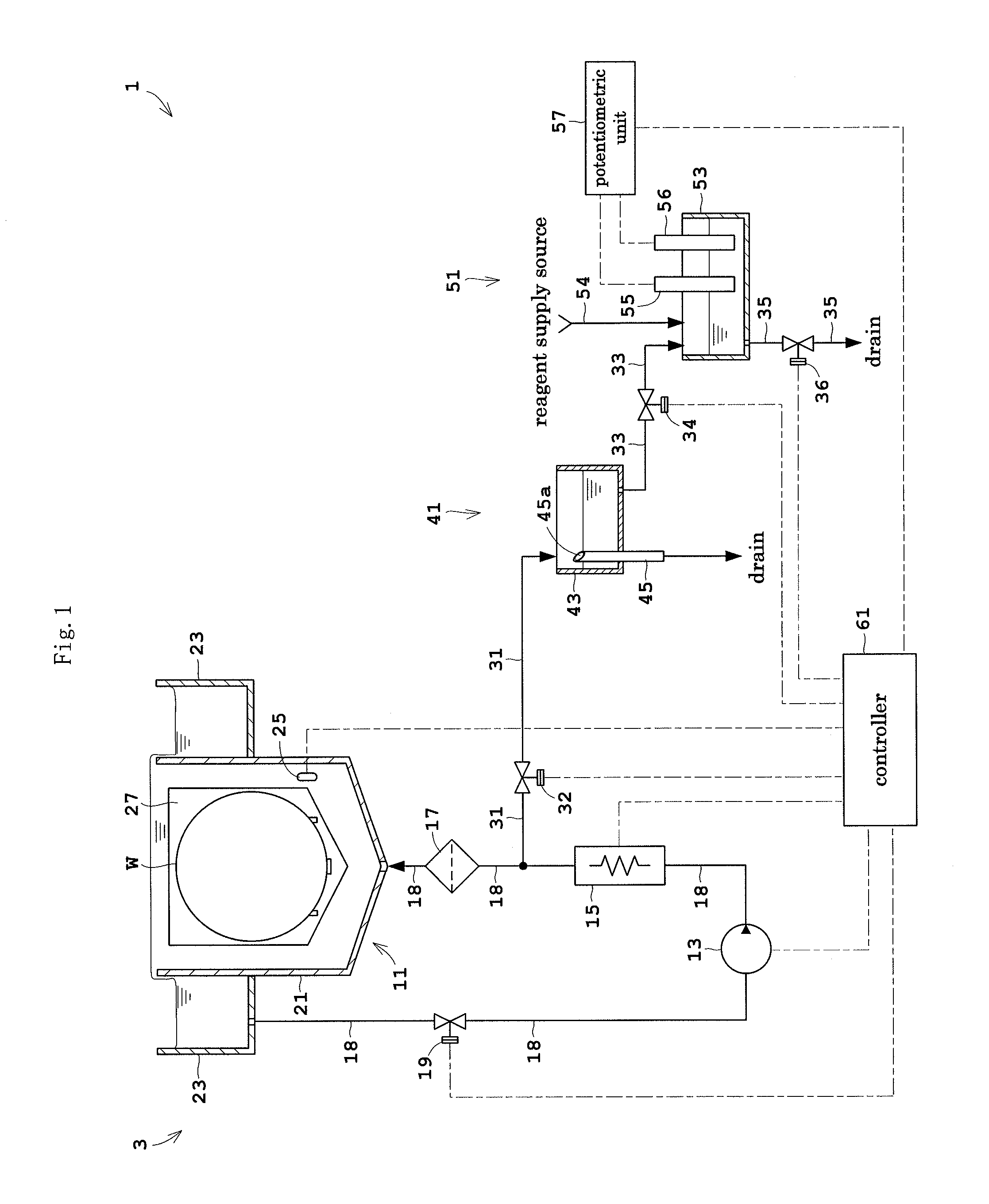

[0048]FIG. 1 shows an outline construction of a substrate treating apparatus 1 according to Embodiment 1. The substrate treating apparatus 1 has a circulating line 3 for circulating the phosphoric acid aqueous solution. The circulating line 3 includes a treating tank 11, a circulating pump 13, a heater 15 for circulation and a filter 17. The treating tank 11 stores the phosphoric acid aqueous solution. The circulating pump 13 feeds the phosphoric acid aqueous solution under pressure. The heater 15 for circulation heats the phospho...

embodiment 2

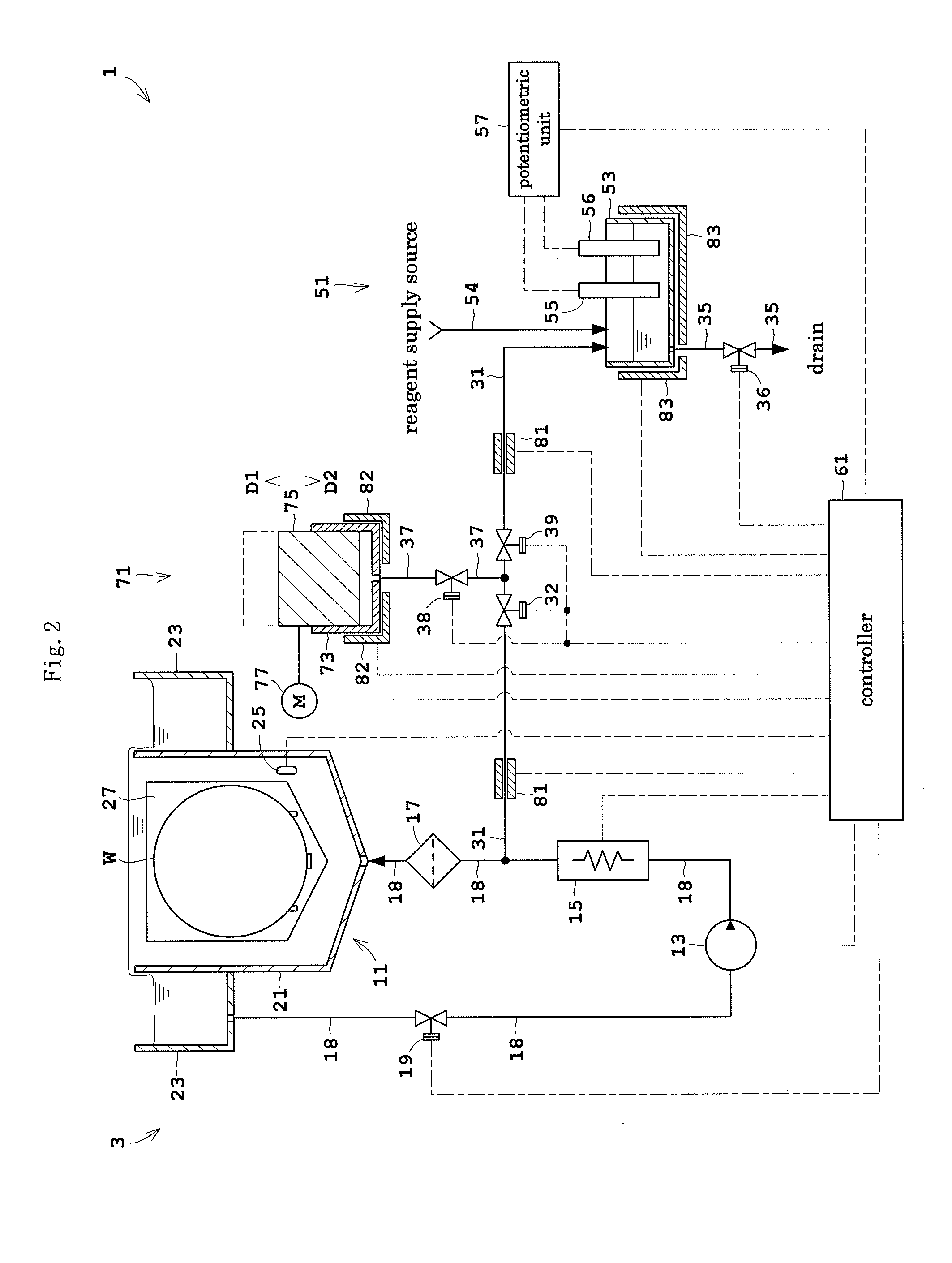

[0078]Next, Embodiment 2 of this invention will be described. FIG. 2 is a view showing an outline construction of a substrate treating apparatus 1 according to Embodiment 2. Like reference signs are used to identify like parts which are the same as in Embodiment 1 and will not particularly be described.

[0079]The substrate treating apparatus 1 according to Embodiment 2 includes a quantity measuring station 71 in place of the quantity measuring station 41 in Embodiment 1. The quantity measuring station 71 is connected to piping 37 further branching from the branch pipe 31. The piping 37 branches from the branch pipe 31 in a position on the secondary side of the switch valve 32. The piping 37 has a switch valve 38 mounted in an intermediate position thereof. The branch pipe 31 further includes a switch valve 39 mounted in an intermediate position thereof. The switch valve 39 is disposed adjacent the secondary side of a junction of the branch pipe 31 and piping 37. The other end of the ...

embodiment 3

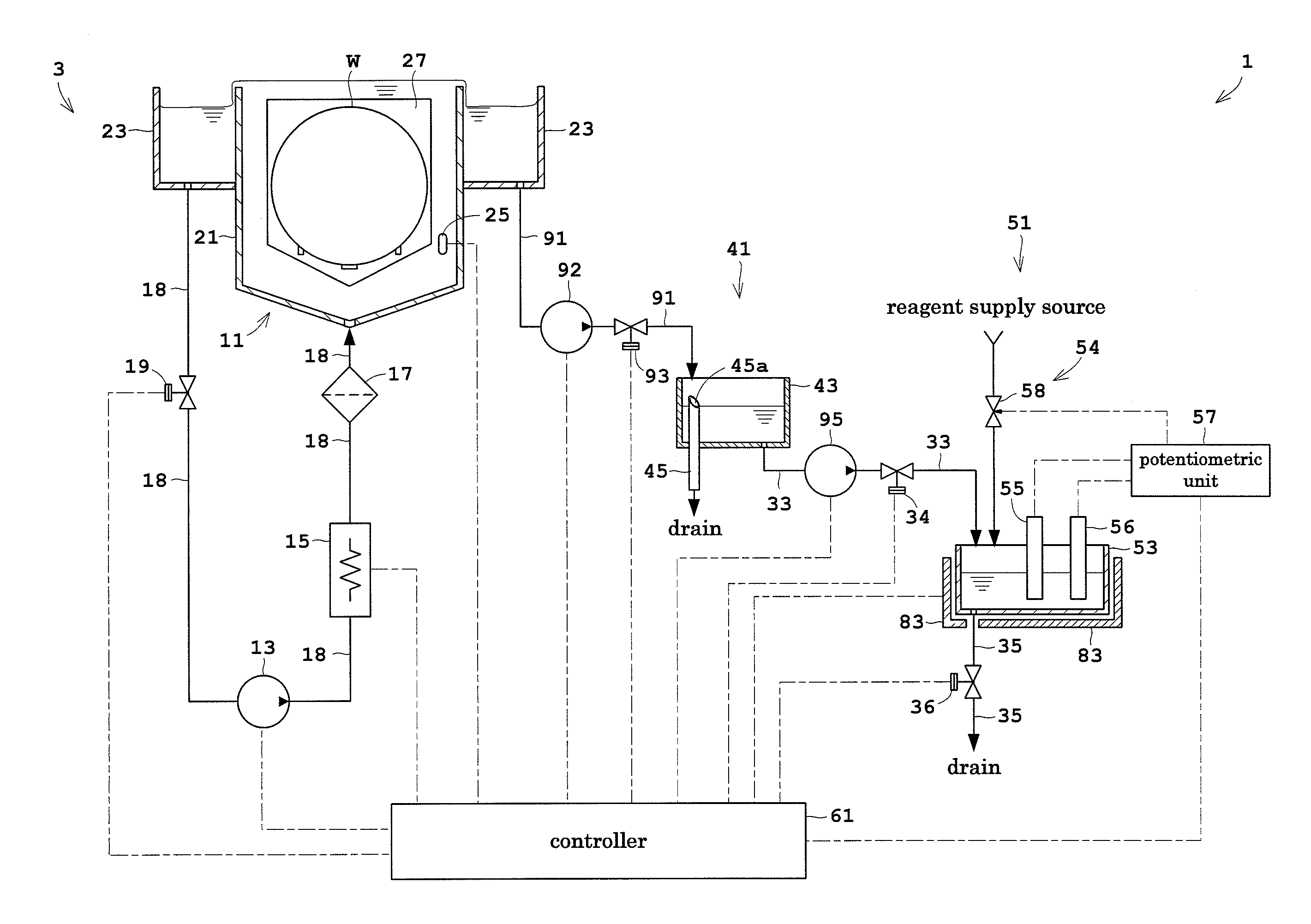

[0093]Next, Embodiment 3 of this invention will be described. FIG. 3 is a view showing an outline construction of a substrate treating apparatus 1 according to Embodiment 3. Like reference signs are used to identify like parts which are the same as in Embodiments 1 and 2 and will not particularly be described.

[0094]The substrate treating apparatus 1 according to Embodiment 3 includes a branch pipe 91 in place of the branch pipe 31 in Embodiment 1. The branch pipe 91 branches from the circulating line 3, off from the outer tank 23. One end of the branch line 91 is connected to the bottom of the outer tank 23. The other end of the branch line 91 is connected to the quantity measuring station 41.

[0095]The branch pipe 91 has a first pump 92 mounted in an intermediate position thereof for feeding the phosphoric acid aqueous solution. A switch valve 93 is disposed on the secondary side of the first pump 92 and the primary side of the quantity measuring station 41.

[0096]The substrate treat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com