Method for absorbing and extracting phosphor and fluorin from phosphoric acid produced in kiln method

A separation method and technology of phosphoric acid, applied in phosphoric acid, phosphorus oxyacid, halogenated silicon compounds, etc., can solve the problems of increased gas absorption, high energy consumption, low separation rate, etc., and achieve easy utilization and reprocessing, wide concentration level , good separation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

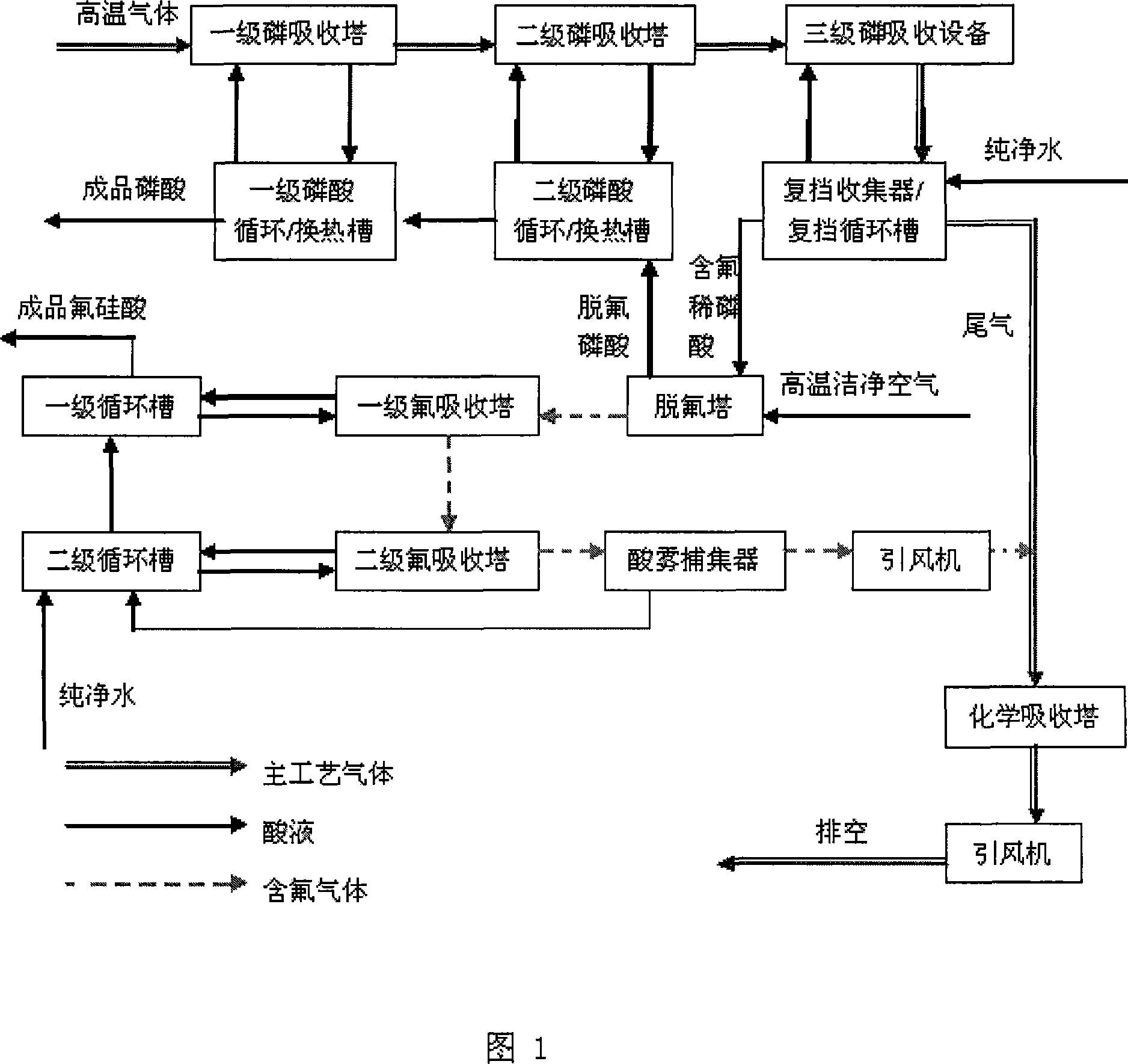

Image

Examples

Embodiment

[0029] The temperature is 452°C, w(P 2 O 5 ): 8.2% of high-temperature kiln gas enters the primary phosphoric acid absorption tower, high-temperature circulating acid in the primary phosphoric acid circulation tank, temperature 84°C, w(H 3 PO 4 ): 85.5%. After the primary phosphoric acid heat exchanger is cooled by low-temperature soft water, phosphoric acid at a temperature of 65°C is filtered through a filter into the acid distribution tank as a finished product, w(H 3 PO 4 ): 85.5%, impurity: 0.0015%; cooling kiln gas, temperature 145°C, w(P 2 O 5 ): 1.58% is introduced into the secondary phosphoric acid absorption tower, the secondary absorption cycle acid, the temperature is 75.2°C, w(H 3 PO 4 ): 55.4% phosphoric acid cooled by low-temperature soft water in the secondary phosphoric acid circulation tank through the secondary phosphoric acid heat exchanger, the temperature is 55.3°C, w(H 3 PO 4 ): 55.4% to primary phosphoric acid circulation tank; low temperature k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com