Method for preparing high-concentration phosphoric acid by direct-reduction of phosphate ore

A high-concentration, phosphate rock technology, applied in the direction of phosphoric acid, phosphorus oxyacid, etc., can solve the problems of low production cost, low acid concentration, high cost, etc., and achieve strong production adaptability, high yield of total phosphorus, and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

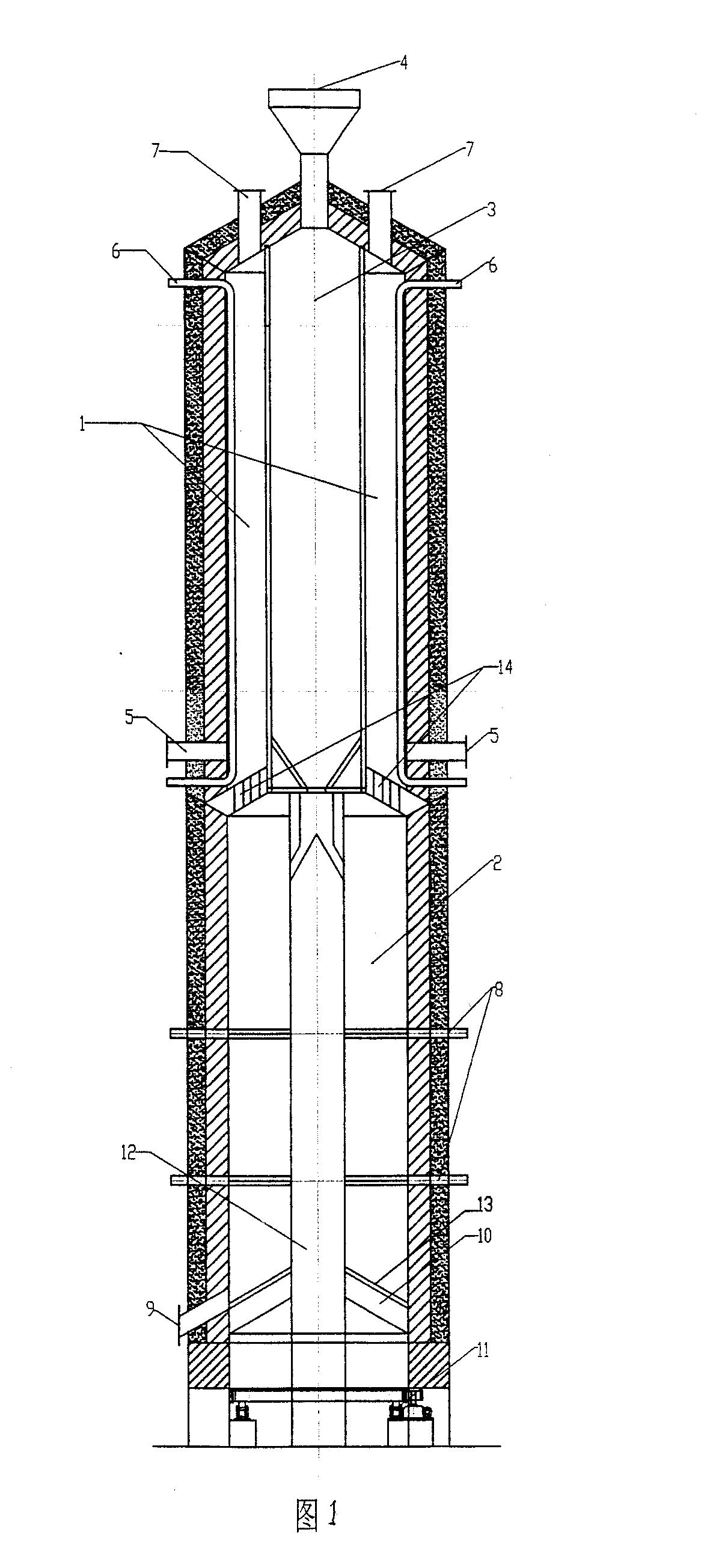

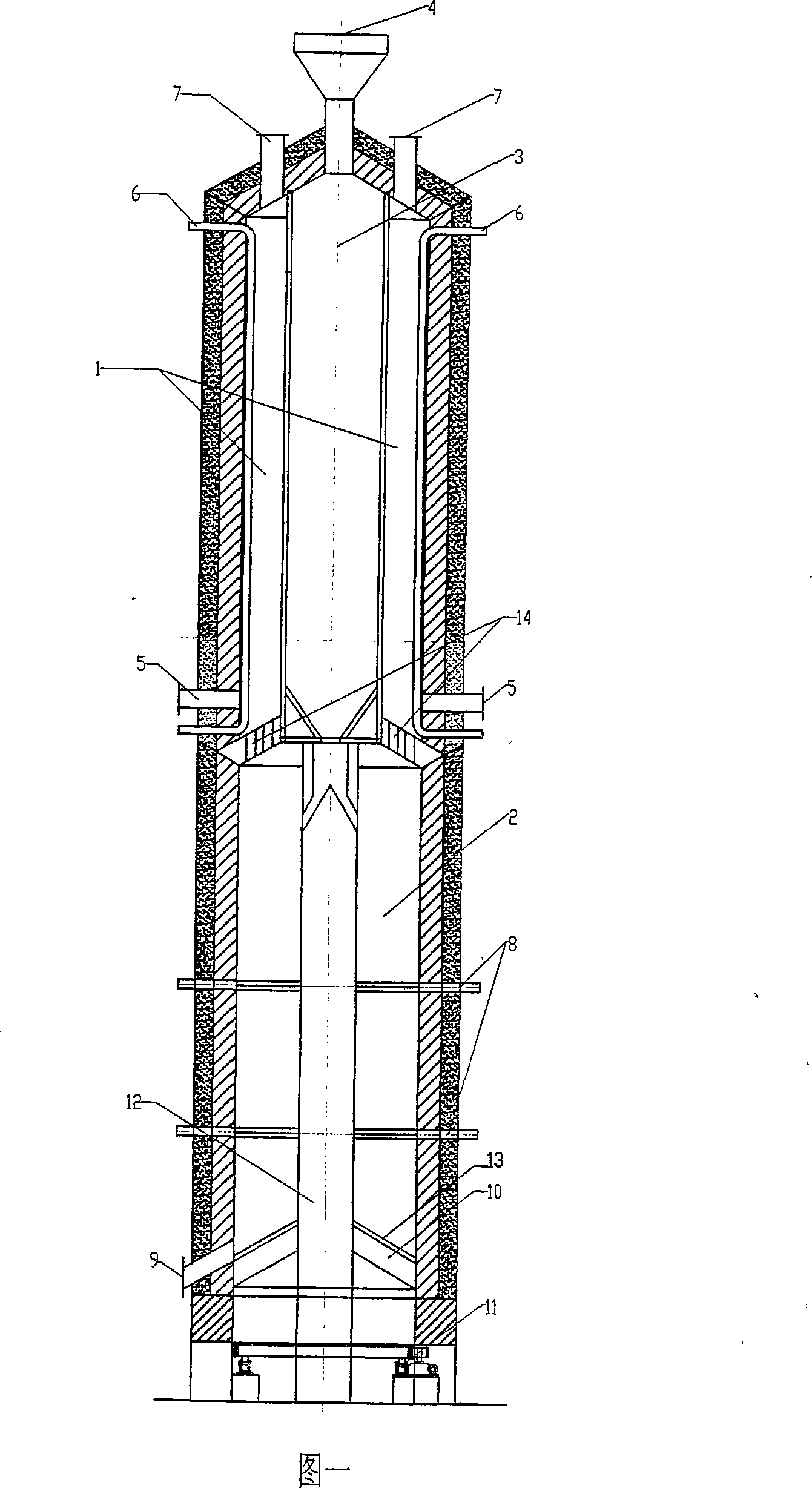

[0017] The process flow of the present invention is as follows: the process of producing phosphoric acid by reducing and oxidizing the blank made of phosphate rock, diatomaceous earth, coke or coal is divided into three zones, a preheating zone, a reducing zone and an oxidation combustion zone, and uses different The composition of the device components is shown in Figure 1. The process method is: the medium and low grade phosphate rock (P 2 o 5 : 17-22%, SiO 2 : 21-27%), diatomaceous earth (SiO 2 ≥68%), coke or coal (fixed carbon content ≥75%) are mixed according to the ratio of 1:0.01-0.96:0.1-0.3, and then ground to 80% or more through 200 mesh powder, and then sprayed with 5- 8% water and 0-1% lignosulfonate are pressed into the required shape of the billet (diameter 10-25mm ball), after drying at 380°C-500°C, put it into the preheating zone of the composite kiln for preheating to 1150°C-1200°C, and then enter the reduction zone, at 1250-1450°C, the coke or coal in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com