Cylinder head with fluid cooling device and method for cooling the cylinder head

A fluid cooling and cylinder head technology, applied in the direction of cylinder head, cylinder, engine components, etc., can solve the problems of increasing danger, achieve the effect of preventing excessive temperature and improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

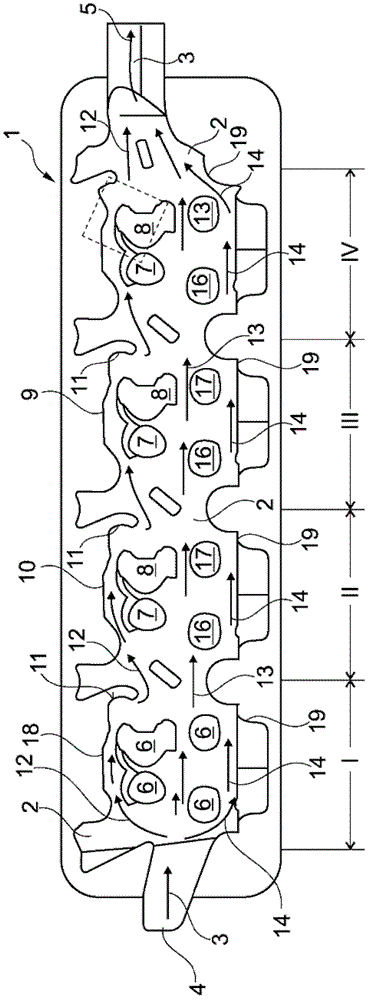

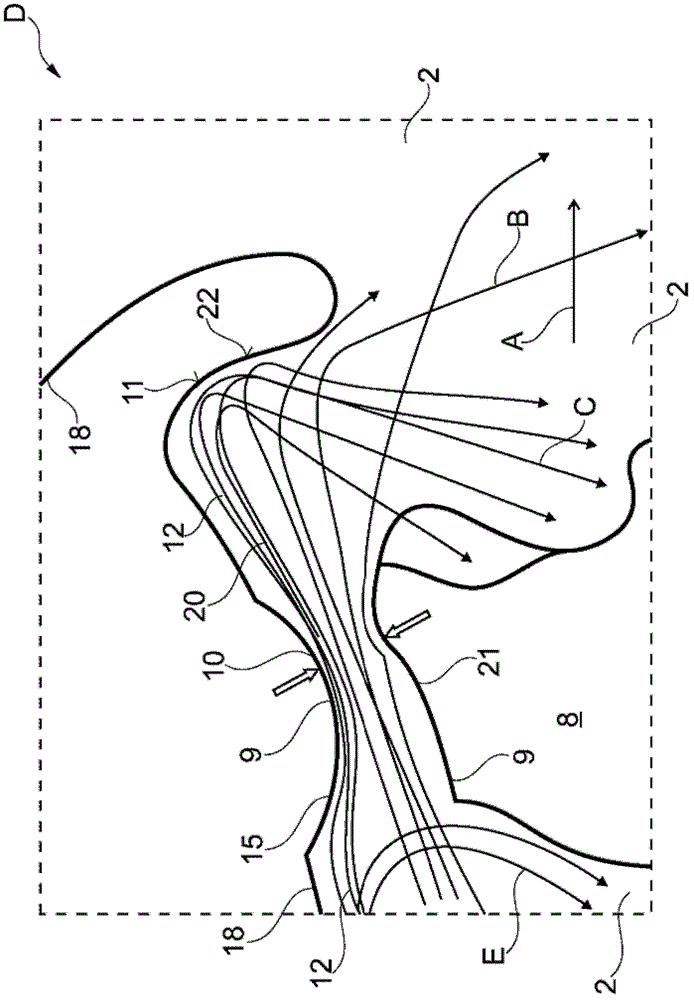

[0019] figure 1 is a schematic illustration of a coolant jacket 2 of a cylinder head 1 of an internal combustion engine with four cylinder zones I, II, III and IV. In the coolant jacket 2 there are four channels 6 each leading to four cylinder regions, wherein the first channel 7 accommodates the nozzles, and the second channel 8 arranged behind the first channel 7 in the flow direction has a spark plug arrangement, In this case, the channels 7 and 8 of the four cylinder ranges I to IV have a third channel 16 with intake valves leading into the individual cylinders and a fourth channel 17 with exhaust valves from the individual cylinders. The coolant jacket 2 is delimited by outer walls 18 and 19 .

[0020] The third and fourth channels 16 and 17 are likewise arranged one behind the other and form a second row of channels in the coolant jacket 2 . The coolant jacket 2 has a coolant inlet 4 and a coolant outlet 5 . The main flow path 3 flows from the coolant inlet 4 to the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com