Method and apparatus for obtaining purified phosphoric acid from phosphoric acid aqueous solution containing plural metal ions

A technology of phosphoric acid aqueous solution and metal ions, which is applied in the direction of phosphoric acid, phosphorus oxyacids, non-metallic elements, etc., can solve the problems of unrecorded coprecipitation, etc., and achieve the effect of stabilizing the etching process and reducing the supply amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

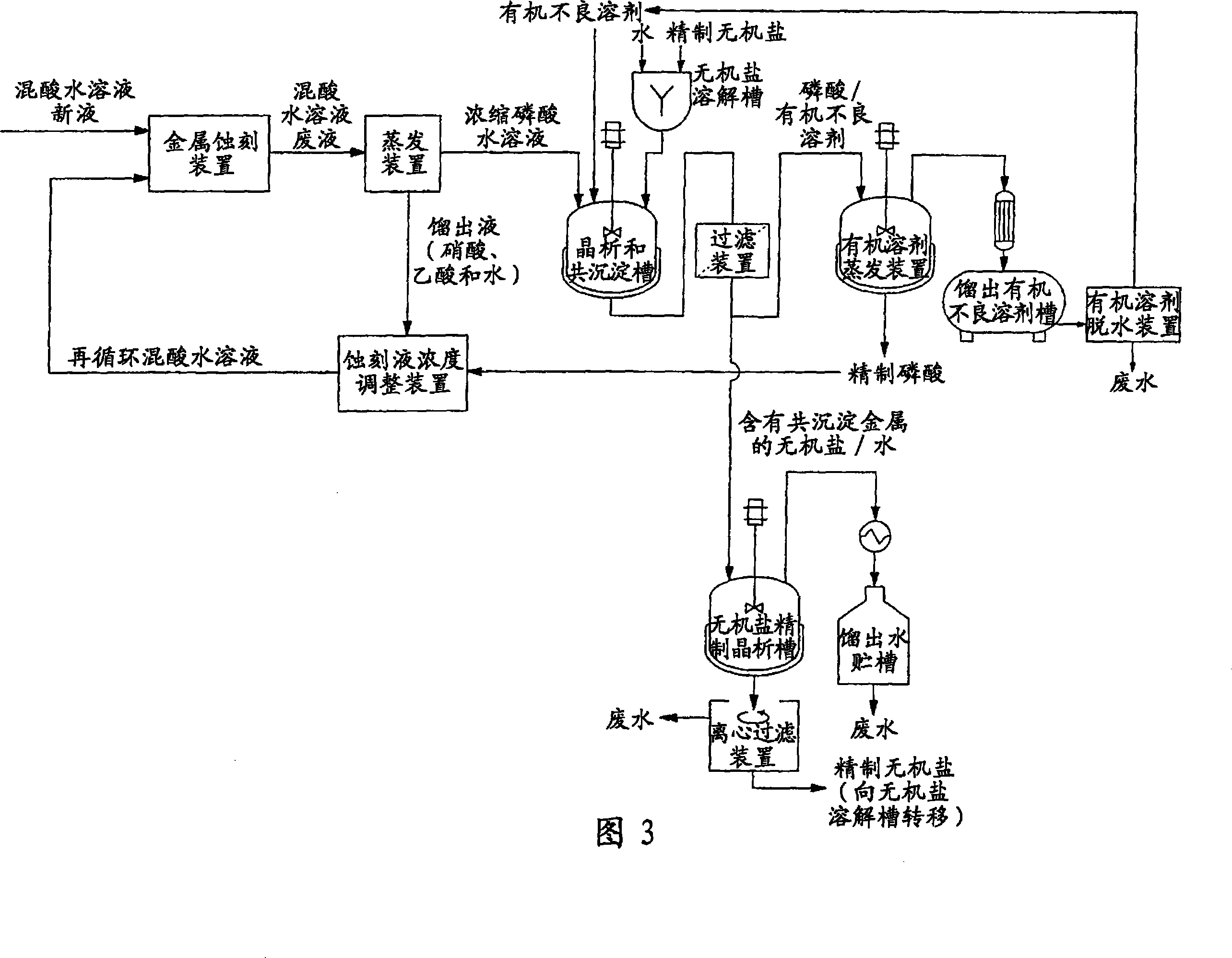

[0089] The recycling system shown in FIG. 3 was used to treat the mixed acid aqueous solution waste liquid in the Al etching process. In addition, the unit of the component is "kg", and "N.D." means below the lower limit of detection.

[0090] The composition of the mixed acid aqueous solution waste liquid (about 100 kg) discharged from the etching step is as follows. Metal ions other than Al and Mo are negligible because they are in extremely small amounts.

[0091] Table 1

[0092] phosphoric acid

[0093] In addition, the composition of the distillate (about 27.8 kg) from the evaporator is as follows.

[0094] Table 2

[0095] phosphoric acid

[0096] In addition, the composition of concentrated phosphoric acid (about 72.2 kg) passed through the evaporator is as follows.

[0097] table 3

[0098] phosphoric acid

[0099] Next, dissolve 7.4 kg of sodium dihydrogen phosphate in 10 kg of water, add to the crystallization and co-precipitation ...

Embodiment 2

[0124] The treatment of the mixed acid aqueous solution waste liquid of the Al etching process similar to Example 1 was performed.

[0125] The composition of the mixed acid aqueous solution waste liquid (about 100kg) discharged from the etching process, the composition of the distillate (about 27.8kg) from the evaporator, and the composition of the concentrated phosphoric acid (about 72.2kg) passing through the evaporator are the same as in Example 1. .

[0126] Next, the same operation as in Example 1 was carried out except that the inorganic salt was changed to 4.43 kg of sodium sulfate and dissolved in 18 kg of water for use. The composition of the treatment liquid (about 354.6 kg) at this stage is as follows.

[0127] In addition, the relationship between the amount of Na and the amount of inorganic substances is the same as in Example 1.

[0128] Table 10

[0129] phosphoric acid

water

Inorganic matter

IPA

Al

Mo

(Na)

65

...

Embodiment 3

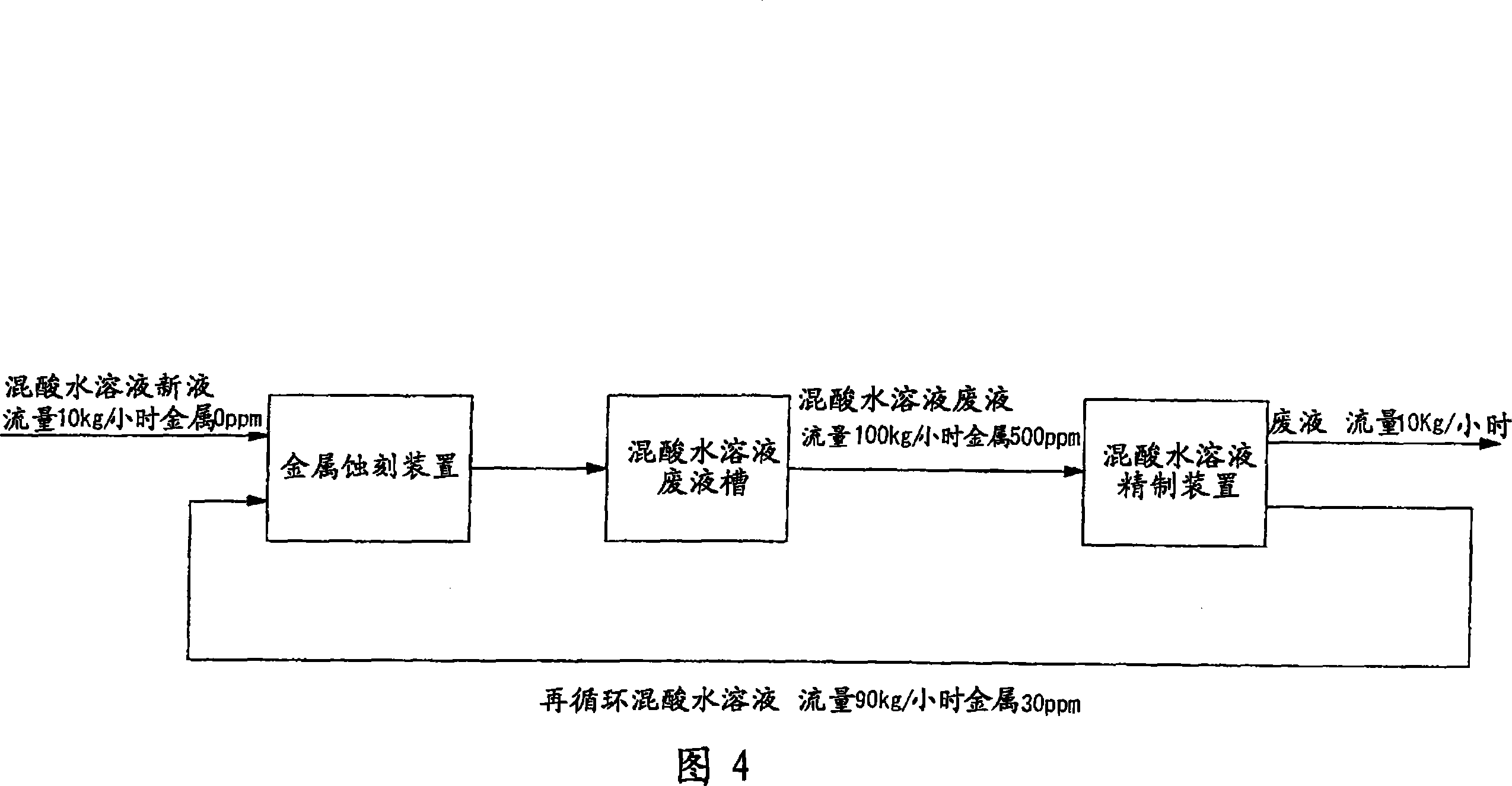

[0141] Using the recirculation system shown in FIG. 3 , it was carried out in the same manner as in Example 1, and the treatment of the mixed acid aqueous solution waste liquid in the Al etching step was performed. Fig. 4 is a diagram showing the material budget for each basic block.

[0142] In this embodiment, in order to keep the metal ion concentration (the total amount of Al, Mo, Na) of the mixed acid aqueous solution tank below 500ppm by weight, and make the treatment capacity of the mixed acid aqueous solution waste liquid be 100kg / hour, recirculate The mixed acid aqueous solution is 90kg / hour, and the metal ion concentration of the recycled mixed acid aqueous solution is suppressed below 30ppm on a weight basis. In the case of supplementing 10kg / hour of mixed acid aqueous solution (replenishment), the upper limit of the amount of etched metal is as follows: 0.0473kg / hour.

[0143] 100kg / hour×0.0005-100kg / hour×0.9×0.00003=0.0473kg / hour

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com