Method and device for purifying furnace gas generated by producing phosphoric acid through blast furnace process

A purification device, the technology of French phosphoric acid, applied in the direction of chemical instruments and methods, phosphoric acid, phosphorus oxyacid, etc., can solve the problems of easy-to-paste bag bag filter, subsequent combustion or reuse of furnace gas, explosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

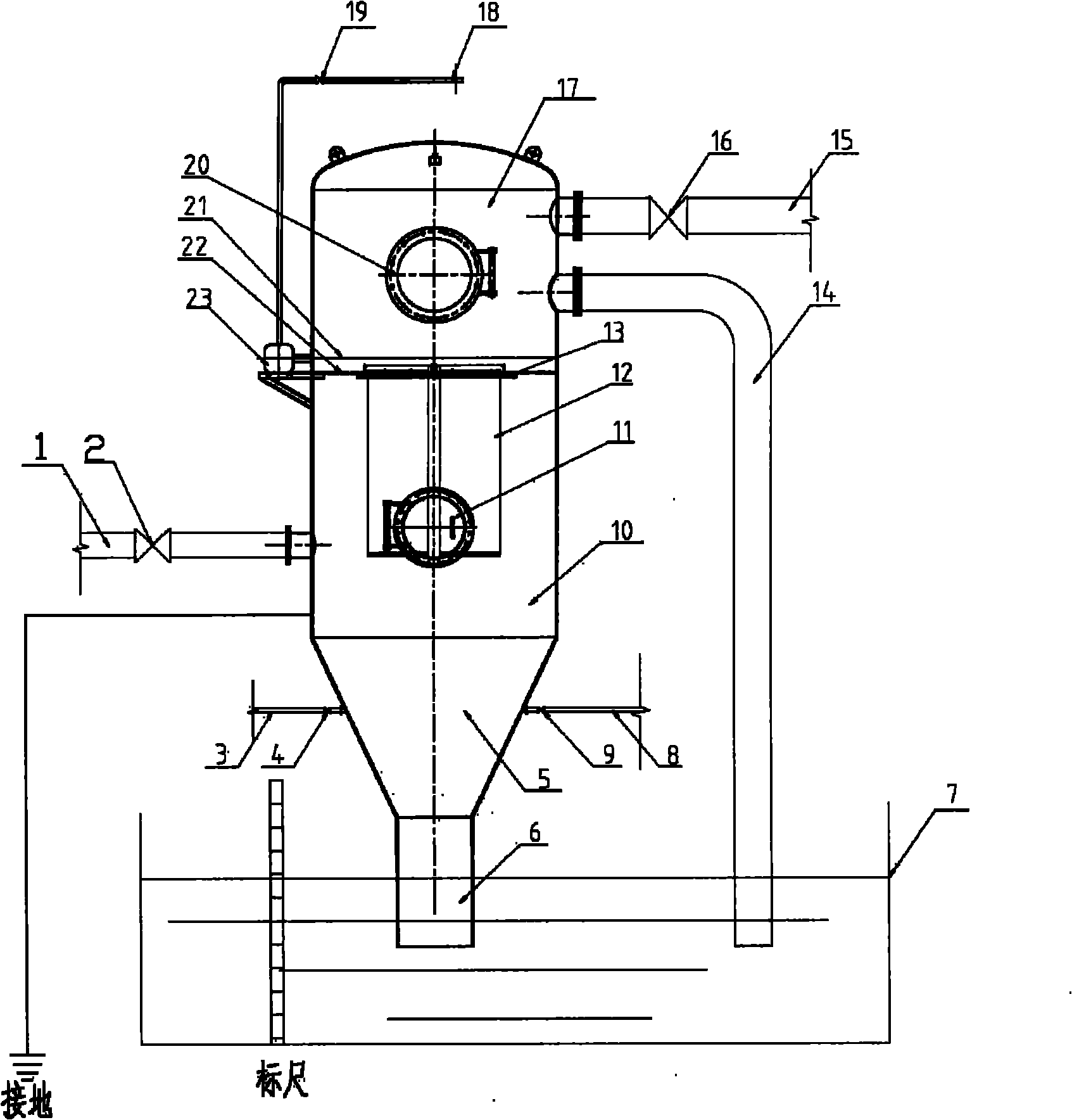

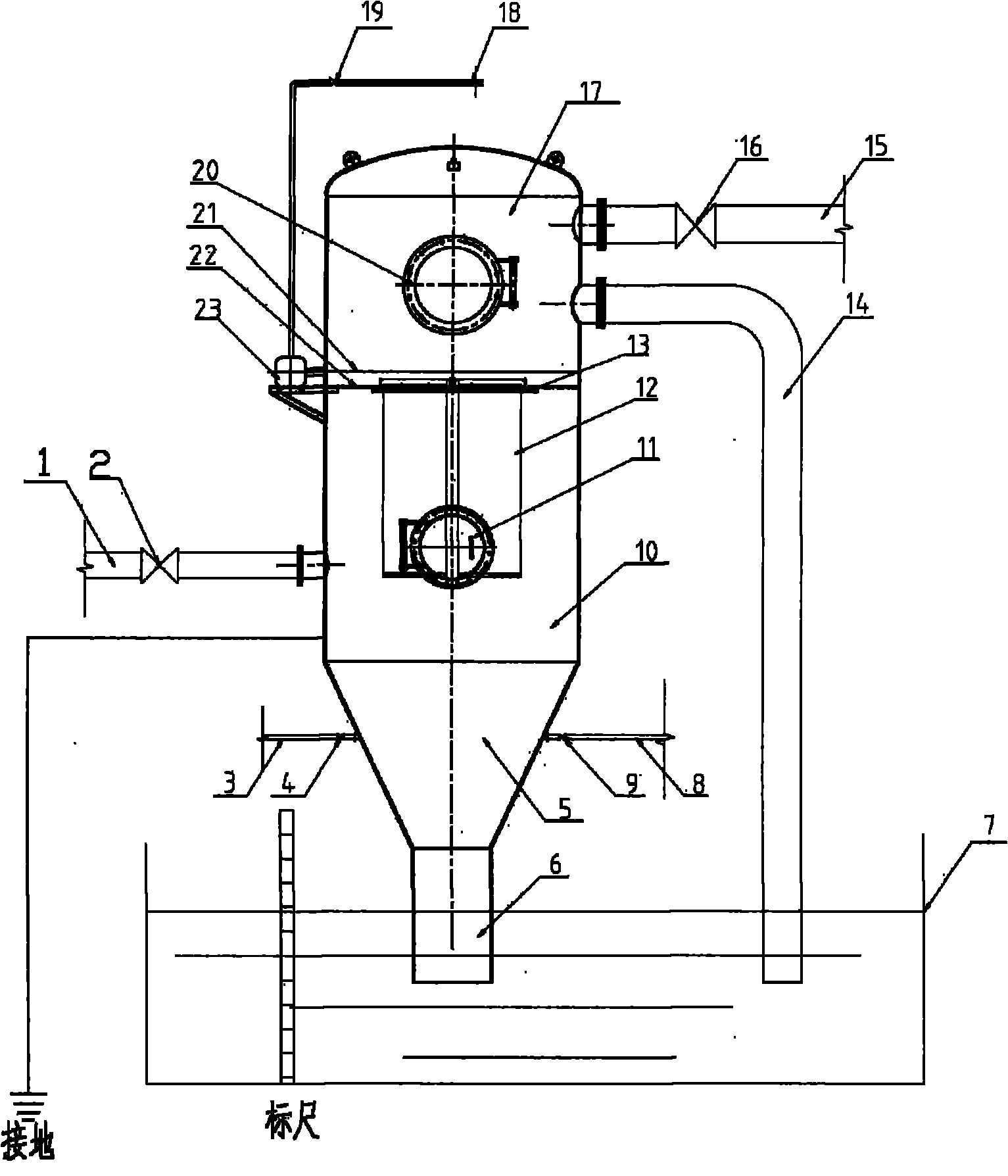

[0029] The method and device for purifying blast furnace phosphoric acid furnace gas according to the present invention will be described below with reference to the accompanying drawings.

[0030] figure 1 It is a schematic diagram of an embodiment of the device for purifying blast furnace phosphoric acid furnace gas according to the present invention. Such as figure 1 As shown, the device includes: an air inlet 1, which is used to supply the furnace gas produced by blast furnace method to the sintered plate dust collector; sintered plate dust collectors 10, 17, which are used to remove dust from the furnace gas; The gas port 15 is used to supply the purified furnace gas to the heat energy recovery device.

[0031] The sintered plate dust collector includes a dust gas chamber (ie dust gas box) 10 and a clean gas room (ie clean gas box) 17, and the dust gas chamber (ie dust gas box) 10 and the clean gas room (ie clean gas box) 17 are respectively set Air inlet 1 and air out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com