Method for producing phosphoric acid and gypsum whiskers by wet process

A technology for gypsum whiskers and wet-process phosphoric acid, applied in the field of producing gypsum whiskers, can solve the problems of slow speed, complicated separation process of phosphoric acid, short reaction time, etc., and achieves the effects of reducing production cost, shortening reaction time and no environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

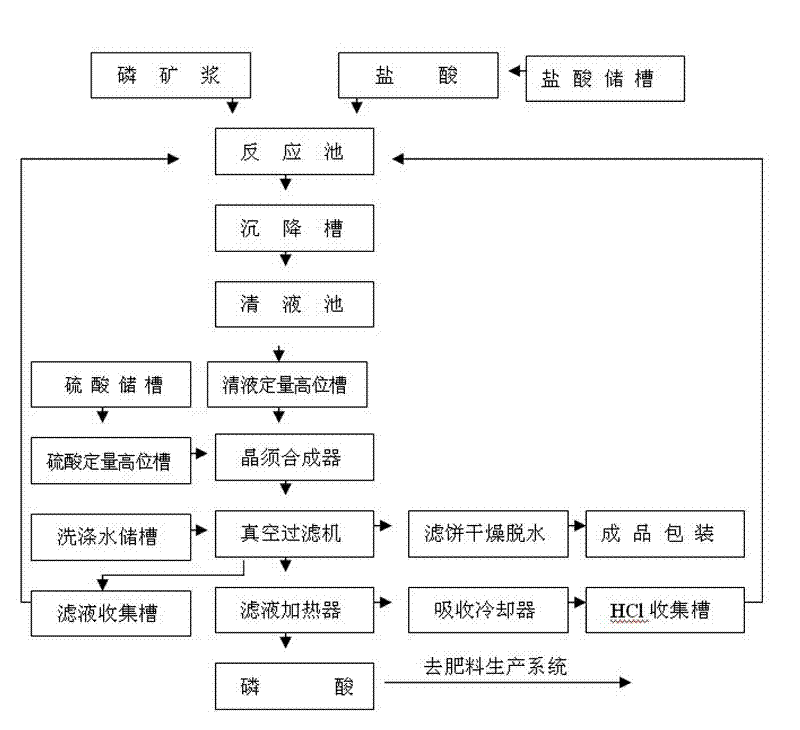

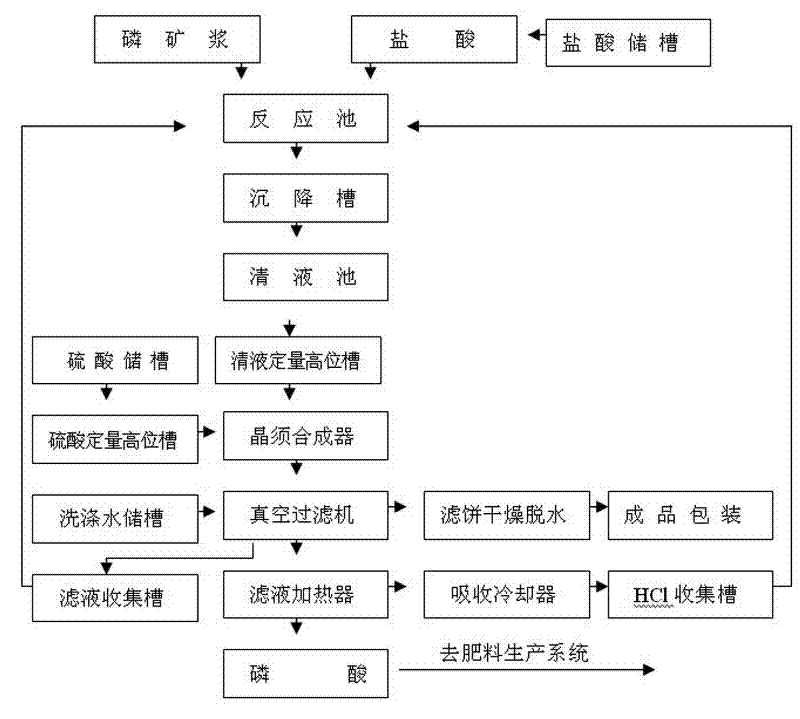

Image

Examples

Embodiment 1

[0019] A method for wet-process phosphoric acid coproduction of gypsum whiskers, comprising the following steps:

[0020] (1) Add excess phosphate rock slurry and hydrochloric acid to the reaction tank, react for 5 minutes under stirring, and precipitate for 30 minutes under static state to form a mixture of calcium dihydrogen phosphate, calcium chloride and phosphoric acid, calcium dihydrogen phosphate naturally precipitates, calcium chloride The mixture with phosphoric acid floats on the upper layer in the form of clear liquid; the moisture content of the phosphate rock slurry is 30%, and the fineness of the phosphate rock powder in the phosphate rock slurry is -100 mesh 60%; the content of the hydrochloric acid is 7%;

[0021] (2) The clear liquid in the step (1) is input into the settling tank through the delivery pump, and the impurities are removed through mechanical filtration to enter the clear liquid pool, and the clear liquid in the clear liquid pool is input into the...

Embodiment 2

[0029] A method for wet-process phosphoric acid coproduction of gypsum whiskers, comprising the following steps:

[0030] (1) Add excess phosphate rock slurry and hydrochloric acid to the reaction tank, react for 20 minutes under stirring, and precipitate for 60 minutes under static state to form a mixture of calcium dihydrogen phosphate, calcium chloride and phosphoric acid, calcium dihydrogen phosphate naturally precipitates, calcium chloride The mixture with phosphoric acid floats on the upper layer in the form of clear liquid; the moisture content of the phosphate rock slurry is 40%, and the fineness of the phosphate rock powder in the phosphate rock slurry is -100 mesh 80%; the content of the hydrochloric acid is 25%;

[0031] (2) The clear liquid in the step (1) is input into the settling tank through the delivery pump, and the impurities are removed through mechanical filtration to enter the clear liquid pool, and the clear liquid in the clear liquid pool is input into t...

Embodiment 3

[0039] A method for wet-process phosphoric acid coproduction of gypsum whiskers, comprising the following steps:

[0040](1) Add excess phosphate rock slurry and hydrochloric acid to the reaction tank, react for 30 minutes under stirring, and precipitate for 90 minutes under static state to form calcium dihydrogen phosphate, calcium chloride and phosphoric acid mixture, calcium dihydrogen phosphate naturally precipitates, calcium chloride The mixture with phosphoric acid floats on the upper layer in the form of clear liquid; the moisture content of the phosphate rock slurry is 45%, and the fineness of the phosphate rock powder in the phosphate rock slurry is -100 mesh 90%; the content of the hydrochloric acid is 36%;

[0041] (2) The clear liquid in the step (1) is input into the settling tank through the delivery pump, and the impurities are removed through mechanical filtration to enter the clear liquid pool, and the clear liquid in the clear liquid pool is input into the cle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com