Safe phosphorus supply device for thermal phosphoric acid production

A thermal phosphoric acid and safe technology, applied in the field of phosphorous chemical industry, to achieve the effect of reducing energy consumption, stable quality and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

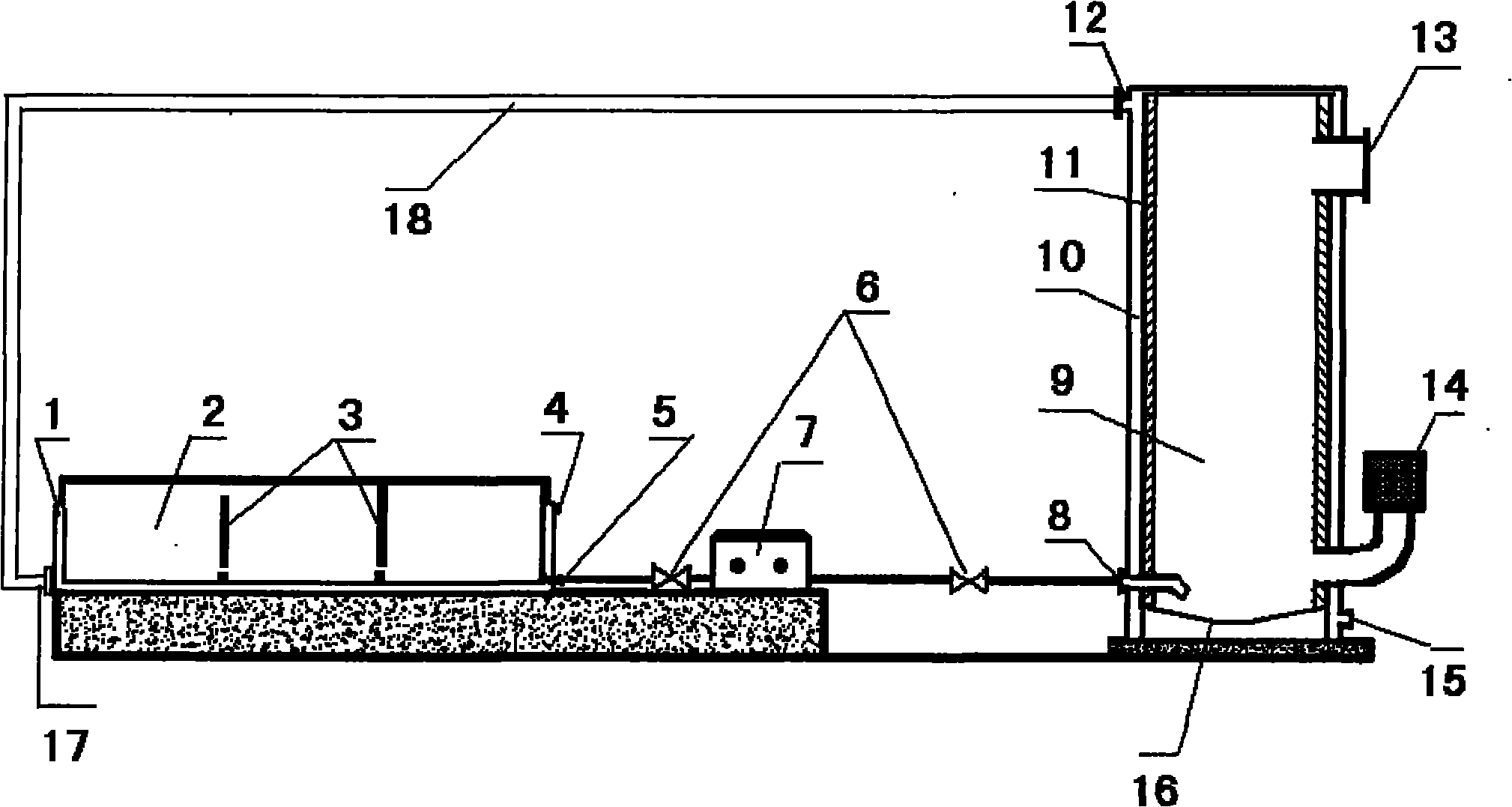

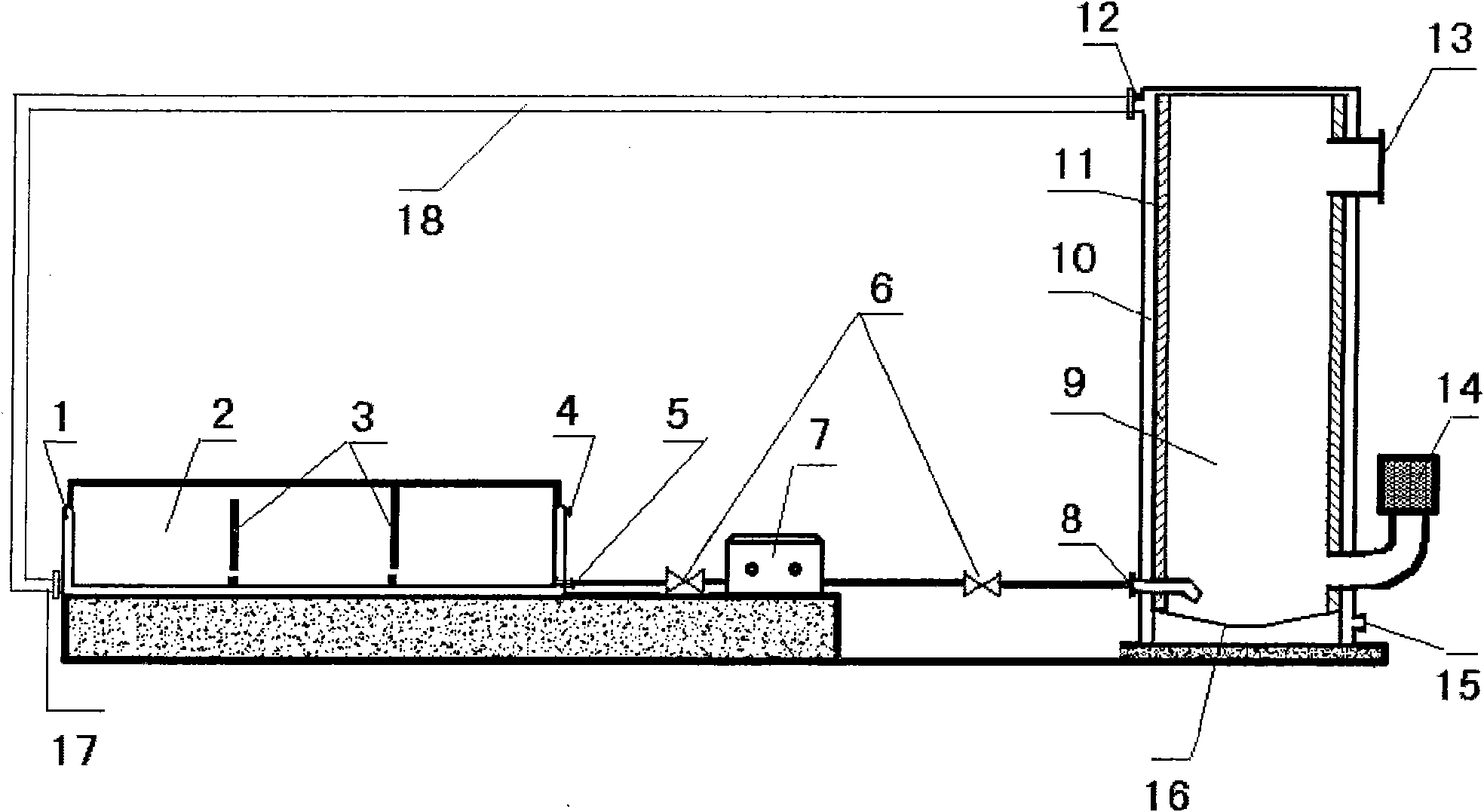

[0015] The safe phosphorus supply device for thermal phosphoric acid production includes a phosphorus melting tank 2, a regulating valve 6, a meter 7, and a combustion furnace 9. The phosphorus-melting tank 2 is fabricated by welding stainless steel, or by welding lead-plated composite material, PYC composite material or glass-steel composite material. The phosphorus-melting tank 2 is provided with one or more sections of phosphorus-melting chambers, and the multi-section phosphorus-melting chambers are separated by partitions 3 . The bottom of the partitions 3 is provided with square or round phosphorus holes, and the partitions 3 are welded to the phosphorus-melting tank 2 . The phosphorus melting tank 2 is provided with a heating jacket 1, the bottom of the jacket 1 is provided with a water inlet 17 and is connected with the water outlet 12 of the combustion furnace 9 by an insulating water pipe 18, and the water inlet of the jacket 1 is connected diagonally to the upper par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com