Method for producing phosphorus pentoxide by phosphorus ore fusion

A technology of phosphorus pentoxide and phosphate rock, which is applied in the field of phosphorus chemical industry, can solve the problems of reduced reduction rate, difficulty in utilization, and poor quality of phosphoric acid, and achieve the effects of improving production efficiency, improving practicability, and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

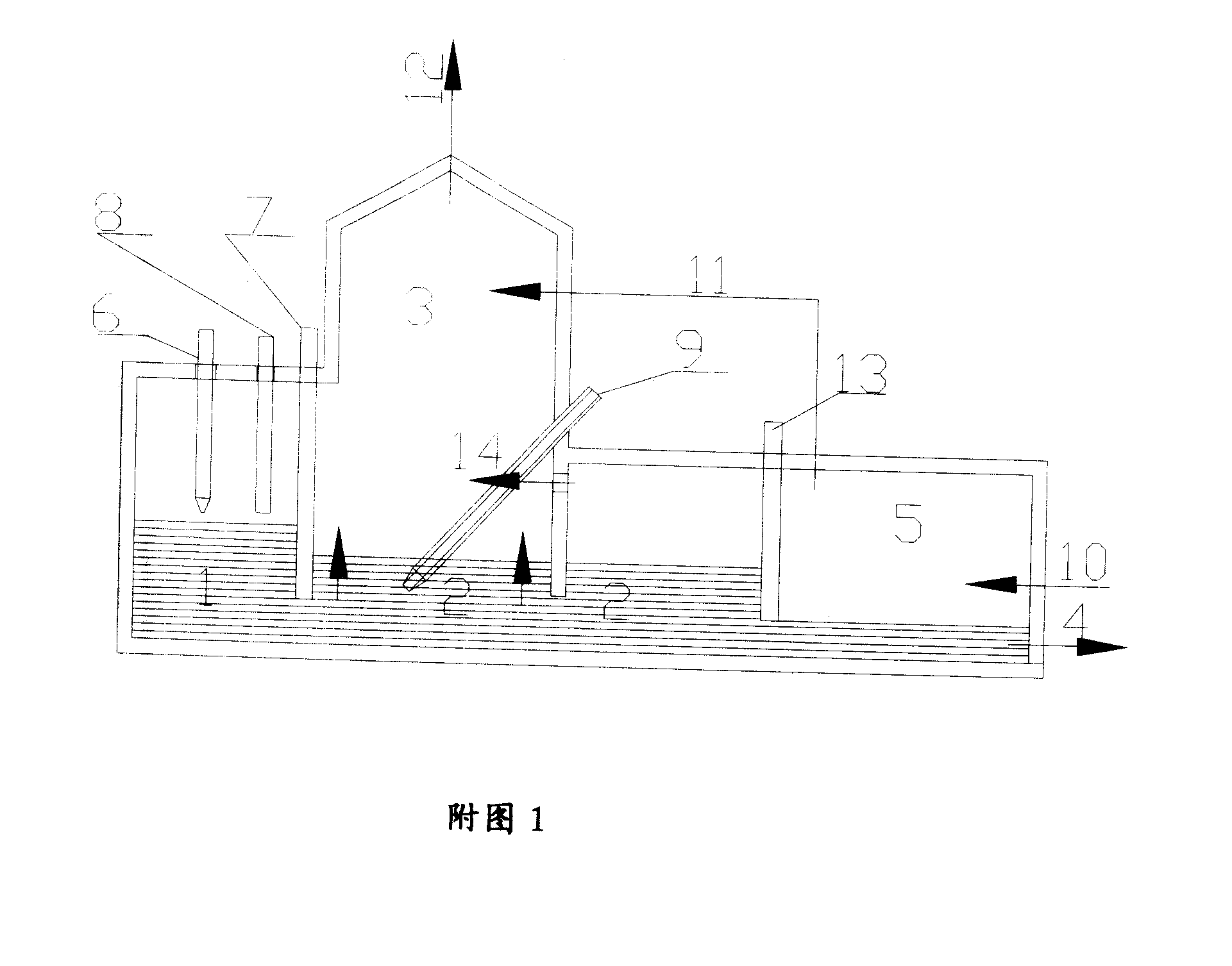

[0050] Use medium-grade ore from Jinhe Phosphate Mine in Sichuan, and silica and coke from Sichuan. See attached table 1 for the quality indicators, and mix ore according to the test data. After drying and dehydrating, the phosphate rock and silica are added to the heating furnace through the feeding port 8. 1, the proportion of phosphate rock and silica is according to the SiO in the mixed material 2 : CaO=1.1:1 control, close the gate 7, 13, start the electrode heater 6, heat and melt the material in the heating furnace 1, detect the temperature of the material at 1432--1490 ° C, open the gate 7 and adjust the opening height, Because the liquid level in the heating furnace 1 is higher than the reduction zone 2 of the reaction furnace, the mixed material flows into the reduction zone 2 of the reaction furnace, and coke is sprayed into the melt in the reduction zone 2 of the reaction furnace with a spray gun 9, and the amount of coke is added according to the reduced phosphate ...

Embodiment 2

[0054] Use high-grade ore from Kaiyang Phosphate Mine in Guizhou, as well as silica and carbon monoxide from Sichuan. See Attached Table 2 for the quality indicators, and mix ore according to the test data. After drying and dehydrating, the phosphate rock and silica are added to the heating furnace through the feeding port 8. In 1, the proportion of phosphate rock and silica is according to the SiO in the mixed material 2 : CaO=0.03: 1 control, close gate 7, 13, start charcoal injection combustion heater 6, guarantee the complete combustion of charcoal, make material heating and melting in heating furnace 1, detect material temperature at 1580 DEG C--1600 DEG C, Open the gate 7 and adjust the opening height, because the liquid level in the heating furnace 1 is higher than the reaction furnace reduction region 2, the mixed material flows into the reaction furnace reduction region 2, and sprays carbon monoxide into the melt in the reaction furnace reduction region 2 with the spra...

Embodiment 3

[0058] Use medium-grade ore from Fuquan phosphate mine in Guizhou, silica from Fuquan, Guizhou, and coal from Weng’an, Guizhou. The quality indicators are shown in Attached Table 3, and the ore is blended according to the test data. After drying and dehydrating, the phosphate rock and silica are fed from the feeding port. 8 into the heating furnace 1, the proportion of phosphate rock and silica is according to the SiO2 in the mixed material 2 : CaO=1.5:1 control, close the gate 7, 13, start the methane combustion heater 6, heat and melt the material in the heating furnace 1, detect the temperature of the material at 1822--1875 ° C, open the gate 7 and adjust the opening Because the liquid level in the heating furnace 1 is higher than the reaction furnace reduction zone 2, the mixed material flows into the reaction furnace reduction zone 2, and coal is sprayed into the melt in the reaction furnace reduction zone 2 with the spray gun 9. 115% of the theoretical carbon content of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com