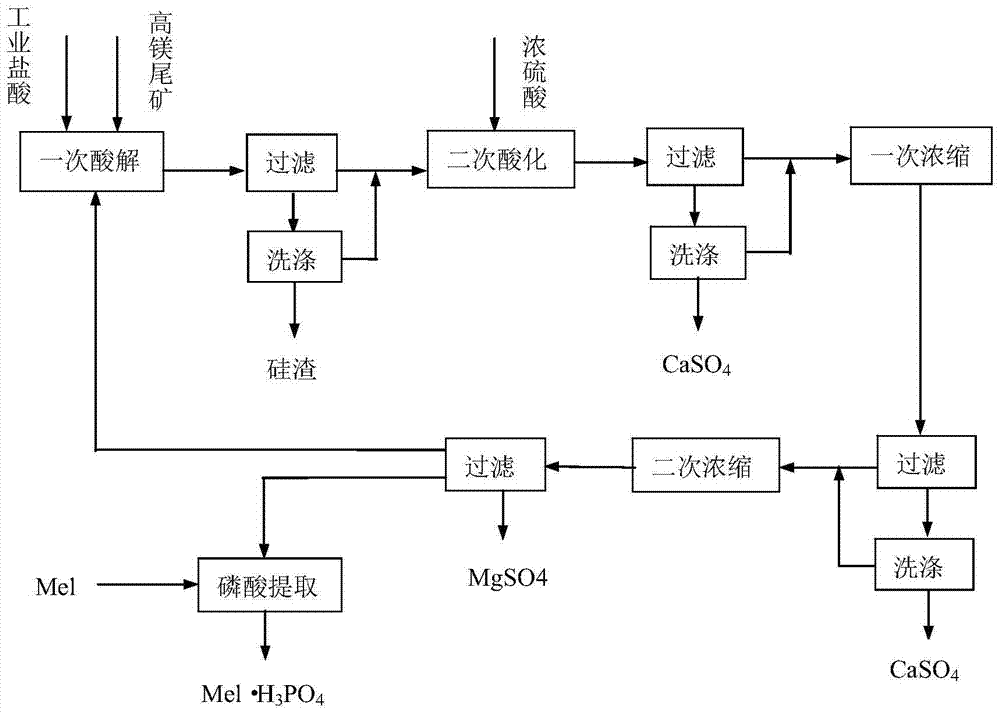

Method for recovering phosphorus in phosphate tailings with high magnesium content and preparing magnesium sulfate by adopting indirect sulfuric acid method

A technology of high magnesium phosphorus tailings and sulfuric acid method is applied in the application field of waste recycling, which can solve the problem of high energy consumption and achieve the effects of low energy consumption, simple and easy process, and good economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The indirect sulfuric acid method reclaims the phosphorus in the high-magnesium phosphorus tailings and prepares the method for magnesium sulfate, and it comprises the following steps:

[0033] Chemical composition of high magnesium phosphorus tailings: P 2 o 5 9.01%, MgO14.47%, CaO34.08%, SiO 2 9.39%

[0034] 1) Measure 500mL of industrial hydrochloric acid with a mass fraction of 33% (10.39mol / L) in a clean three-necked flask, weigh 261.8g of high-magnesium phosphorus tailings powder, and gradually add high-magnesium phosphorus tailings into the three-necked flask, After adding ore. Turn on the condensed water, start stirring, and reflux at 60°C for 30 minutes to obtain the primary acidolysis filtrate and silicon slag. Filtrate at 60°C, wash the silicon slag three times with 100mL distilled water, and mix the first water washing solution and the first acid hydrolysis filtrate;

[0035] 2) Put the mixture obtained in step 1) in a dry beaker, measure 132mL of 98% s...

Embodiment 2

[0040] The indirect sulfuric acid method reclaims the phosphorus in the high-magnesium phosphorus tailings and prepares the method for magnesium sulfate, and it comprises the following steps:

[0041] Chemical composition of high magnesium phosphorus tailings: P 2 o 5 8.02%, MgO15.76%, CaO35.18%, SiO 2 4.94%

[0042]1) Put 510mL of industrial hydrochloric acid with a mass concentration of 33% (10.39mol / L) in a clean three-necked flask, weigh 261.8g of high-magnesium phosphorus tailings powder, gradually add high-magnesium phosphorus tailings into the three-necked flask, add ore After finishing. Turn on the condensed water, start stirring, and reflux at 40°C for 20 minutes to obtain the primary acidolysis filtrate and silicon slag. Filtrate at 60°C, wash the silicon slag three times with 100mL distilled water, and mix the first water washing solution and the first acid hydrolysis filtrate;

[0043] 2) Put the mixture obtained in step 1) in a dry beaker, measure 160mL of 98...

Embodiment 3

[0048] The indirect sulfuric acid method reclaims the phosphorus in the high-magnesium phosphorus tailings and prepares the method for magnesium sulfate, and it comprises the following steps:

[0049] Chemical composition of high magnesium phosphorus tailings: P 2 o 5 6.57%, MgO16.38%, CaO34.27%, SiO 2 7.39%

[0050] 1) Measure 490mL of industrial hydrochloric acid with a mass concentration of 34% (10.81mol / L) in a clean three-necked flask, weigh 261.8g of high-magnesium phosphorus tailings powder, and gradually add high-magnesium phosphorus tailings into the three-necked flask, After adding ore. Turn on the condensed water, start stirring, and reflux at 30°C for 40 minutes to obtain the primary acidolysis filtrate and silicon slag. Filtrate at 60°C, wash the silicon slag three times with 100mL distilled water, and mix the first water washing solution and the first acid hydrolysis filtrate;

[0051] 2) Put the mixture obtained in step 1) in a dry beaker, measure 170mL of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com