Coiled tubing supercritical CO2 jet fracturing method

A supercritical, CO2 technology, applied in the direction of liquid/gas jet drilling, earthwork drilling, mining fluid, etc., can solve the problems of reducing reservoir permeability, reducing fracturing effect, reservoir secondary damage, etc., to improve The effect of single well production and recovery, lower system injection pressure requirements, and low rock-breaking threshold pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

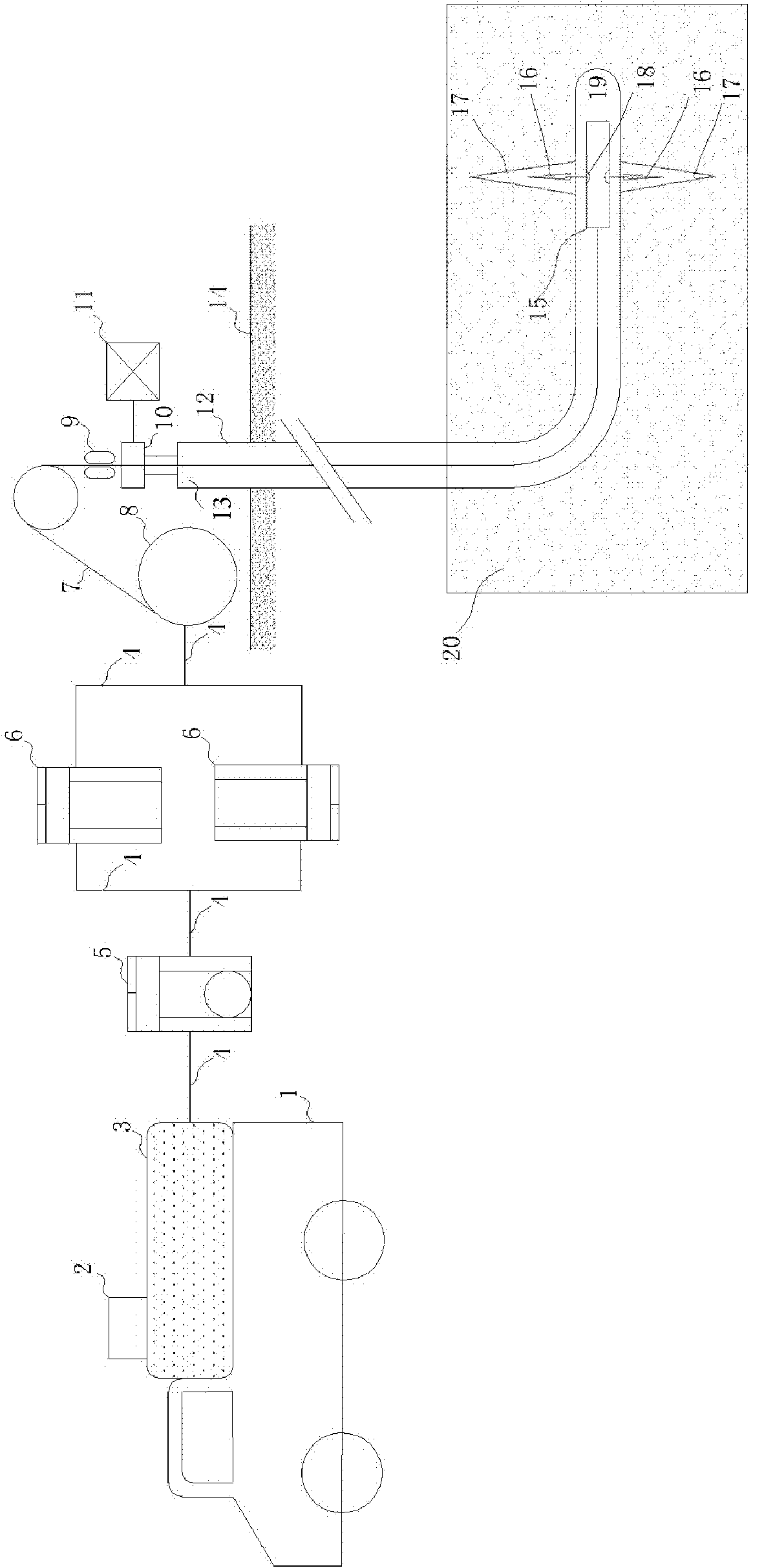

[0048] Coiled tubing supercritical CO provided by the present invention 2 Jet fracturing method introduces supercritical CO 2 As a fracturing fluid, the fluid can give full play to the supercritical CO 2 Based on the respective advantages of coiled tubing and coiled tubing, the method may include the following specific steps:

[0049] 1. Well cleaning treatment:

[0050] Use a drift gauge to drill the well, and wash the well with clean water or well flushing fluid (well flushing fluid commonly used in this field is enough), on the one hand, to prevent tools from being blocked or stuck, and on the other hand, to prevent debris in the wellbore from fracturing During the process, it enters the deep formation and pollutes the reservoir;

[0051] 2. Perforation treatment:

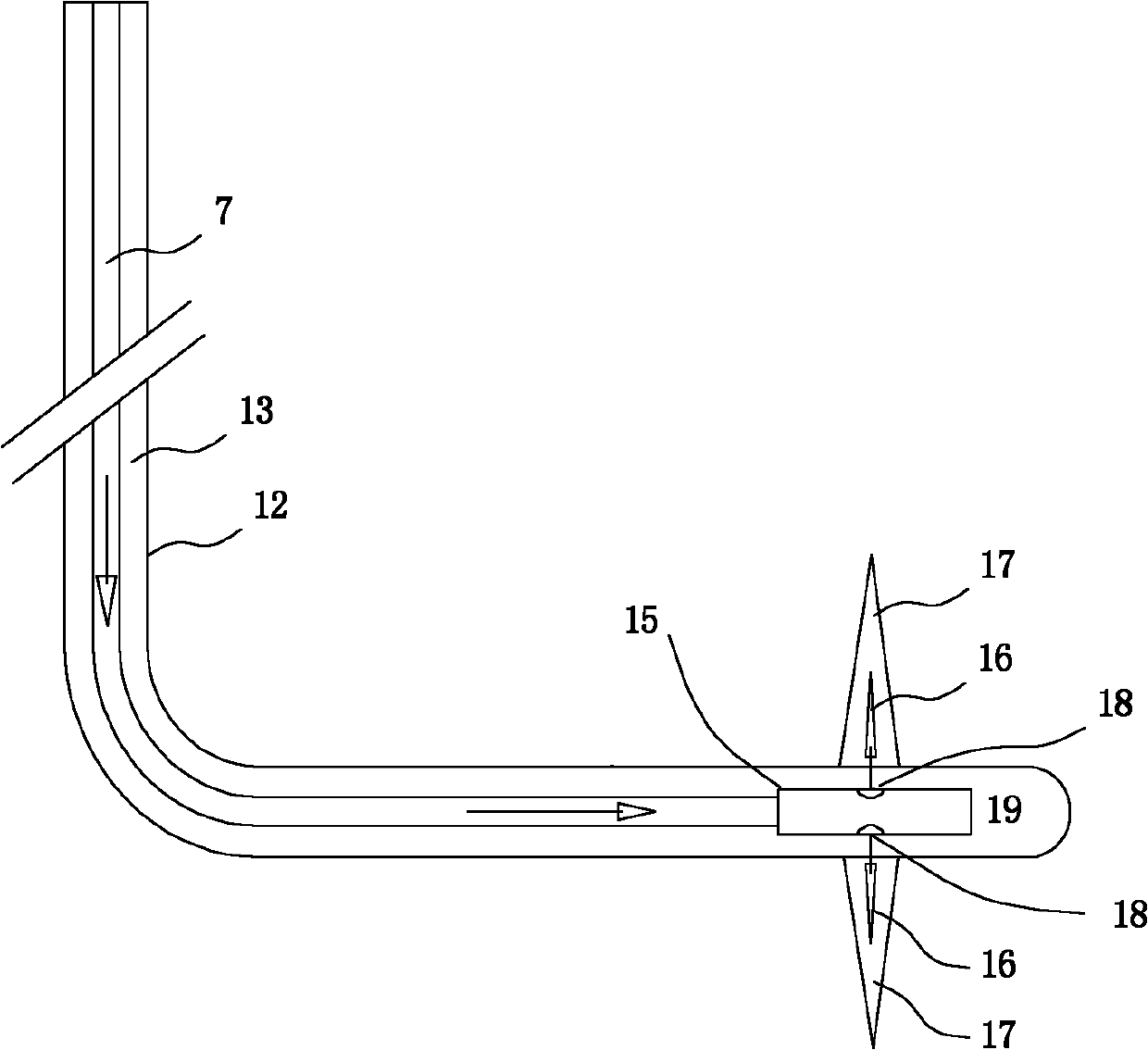

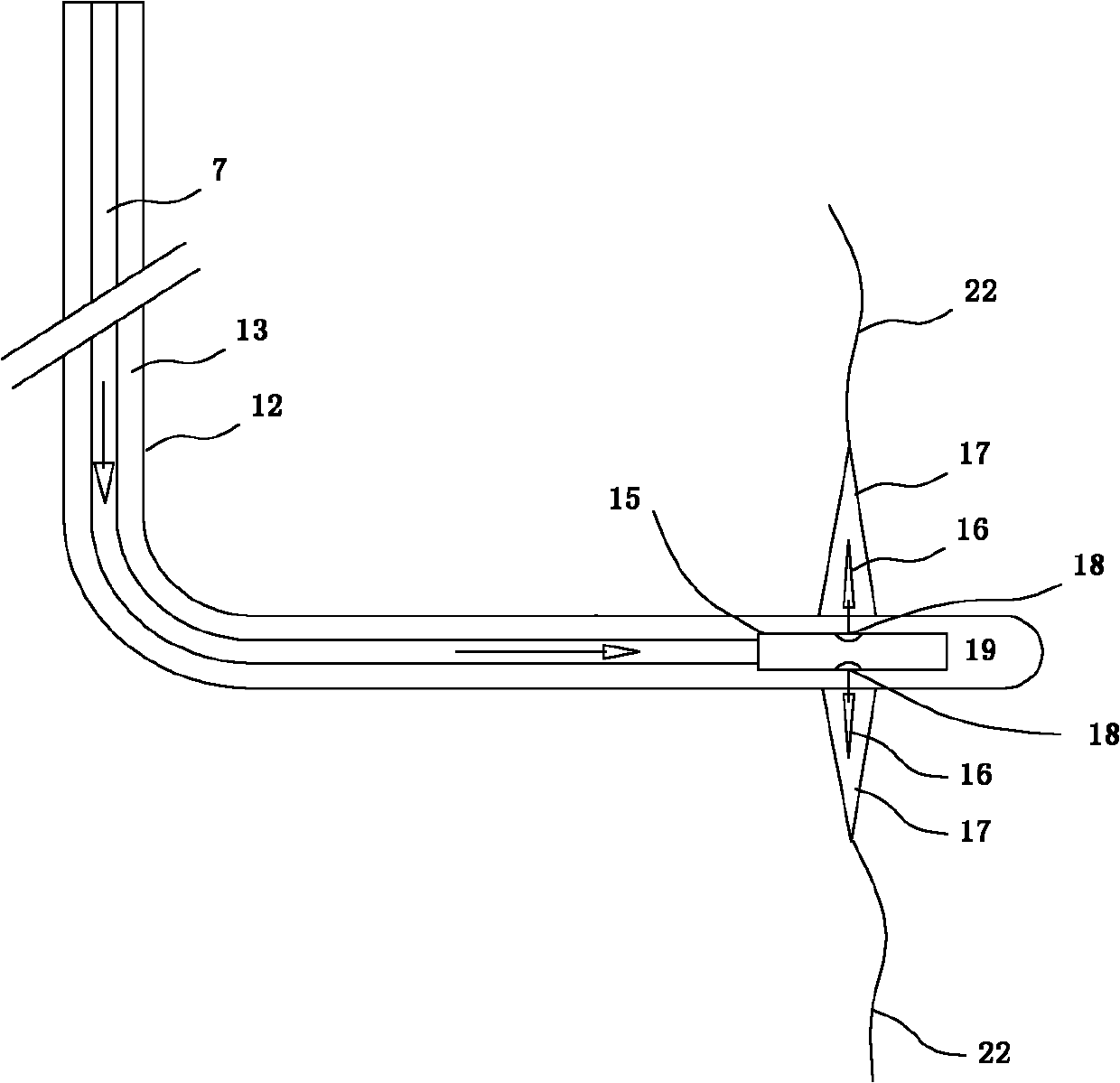

[0052] figure 1 Coiled tubing supercritical CO shown 2 Schematic diagram of jet staged fracturing process. When performing the first stage of sandblasting perforation, the fracturing tool 15 is first lower...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com