A device and method for unloading a liquefied natural gas tank car

A technology of liquefied natural gas and unloading device, which is applied to container filling method, container discharge method, fixed capacity gas storage tank, etc., can solve the problems of inconvenient connection control, occupying space, increasing danger, etc., and achieves clean recovery and convenient operation. , the effect of high recycling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

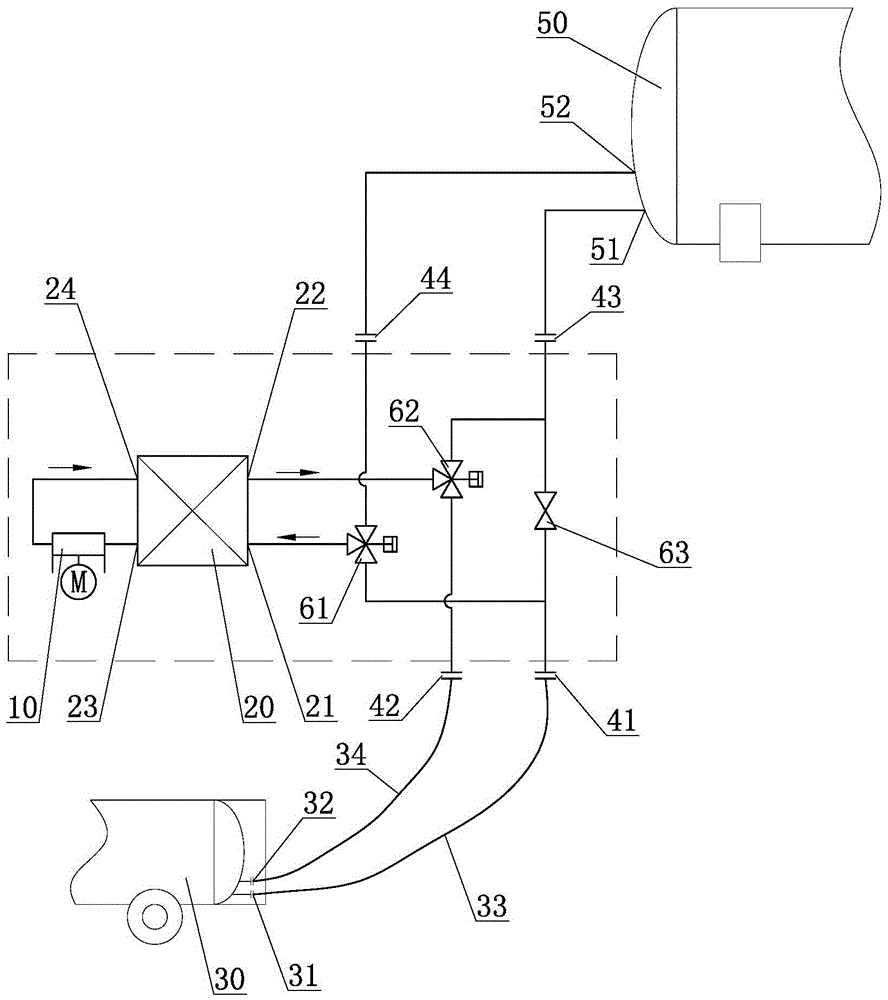

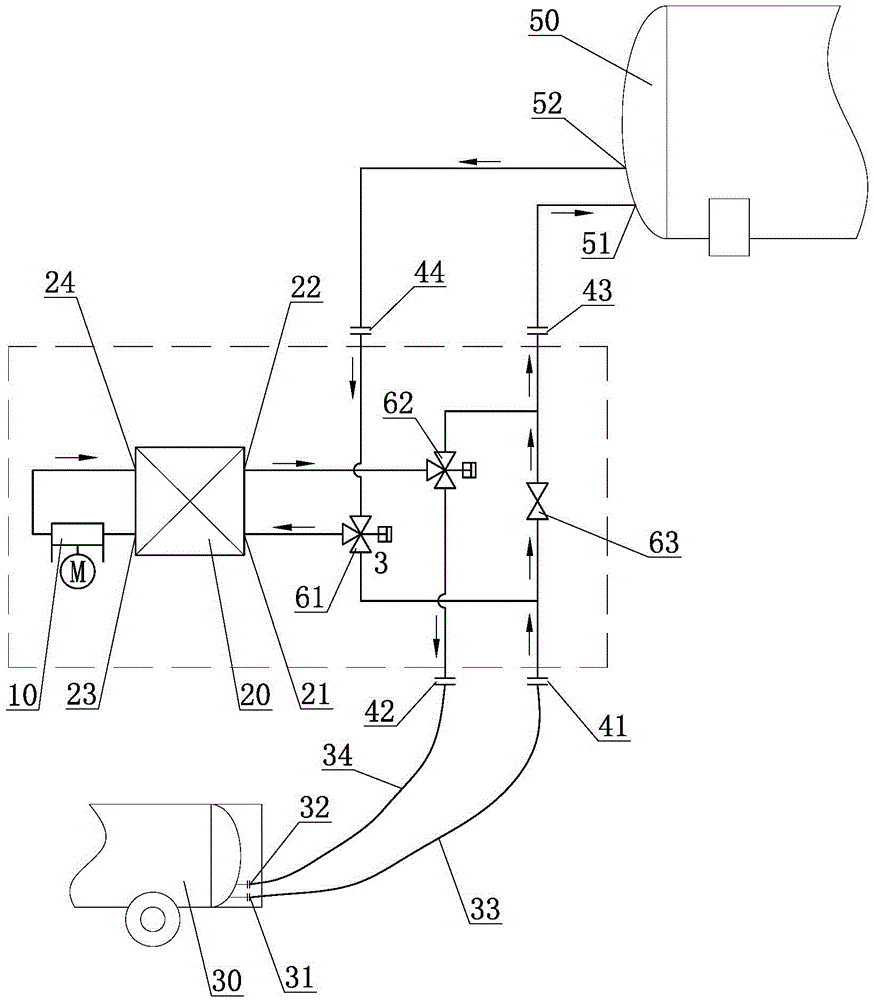

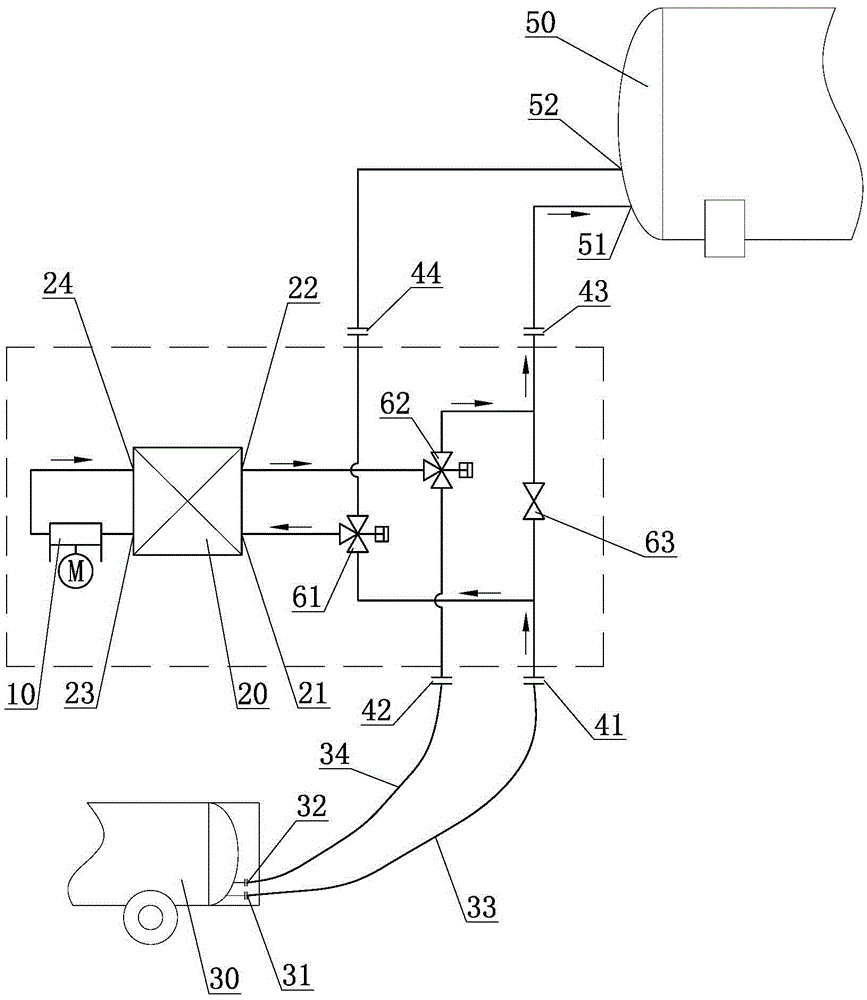

[0035] Such as figure 1 , a liquefied natural gas tank car unloading device, the liquefied natural gas and BOG in the liquefied natural gas tank car are unloaded to the liquefied natural gas storage tank; comprising a compressor 10, a cooler 20; the unloading device is provided with a liquefied natural gas tank car 30 The integrated input interface 41 connected to the liquid phase outlet 31, the gas phase output interface 42 connected to the gas phase outlet 32 of the LNG tank car, the integrated output interface 43 connected to the liquid inlet 51 of the LNG storage tank 50, and the gas phase port connected to the LNG storage tank The gas phase input interface 44 connected by 52; the integrated input interface, the gas phase output interface, the integrated output interface, and the gas phase input interface are interfaces with opening and closing functions.

[0036] The cooler is provided with a pipeline input interface 21, a pipeline output interface 22, a compressor inpu...

Embodiment 2

[0050] Such as figure 1 , a method for unloading a liquefied natural gas tank car, the method is to unload the liquefied natural gas and BOG in the liquefied natural gas tank car to the liquefied natural gas storage tank by using the liquefied natural gas tank car unloading device (hereinafter referred to as the unloading device) of the first embodiment; The steps of the method include:

[0051] a. connect the liquid phase outlet 31 of the liquefied natural gas tank car to the comprehensive input interface 41 of the unloading device through the unloading hose 33, connect the gas phase outlet 32 of the liquefied natural gas tank car to the gas phase output interface 42 of the unloading device through the unloading hose 34, and connect The liquid inlet 51 of the LNG storage tank is connected to the integrated output interface 43 of the unloading device, and the gas phase interface 52 of the LNG storage tank is connected to the gas phase input interface 44 of the unloading devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com