Multifunction straw chopping ensilage machine

A silage, multi-functional technology, applied in cutters, harvesters, cutting equipment and other directions, can solve the problems of inability to stubble, poor palatability, difficult to digest, and achieve the effect of strong adaptability, high efficiency and light load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

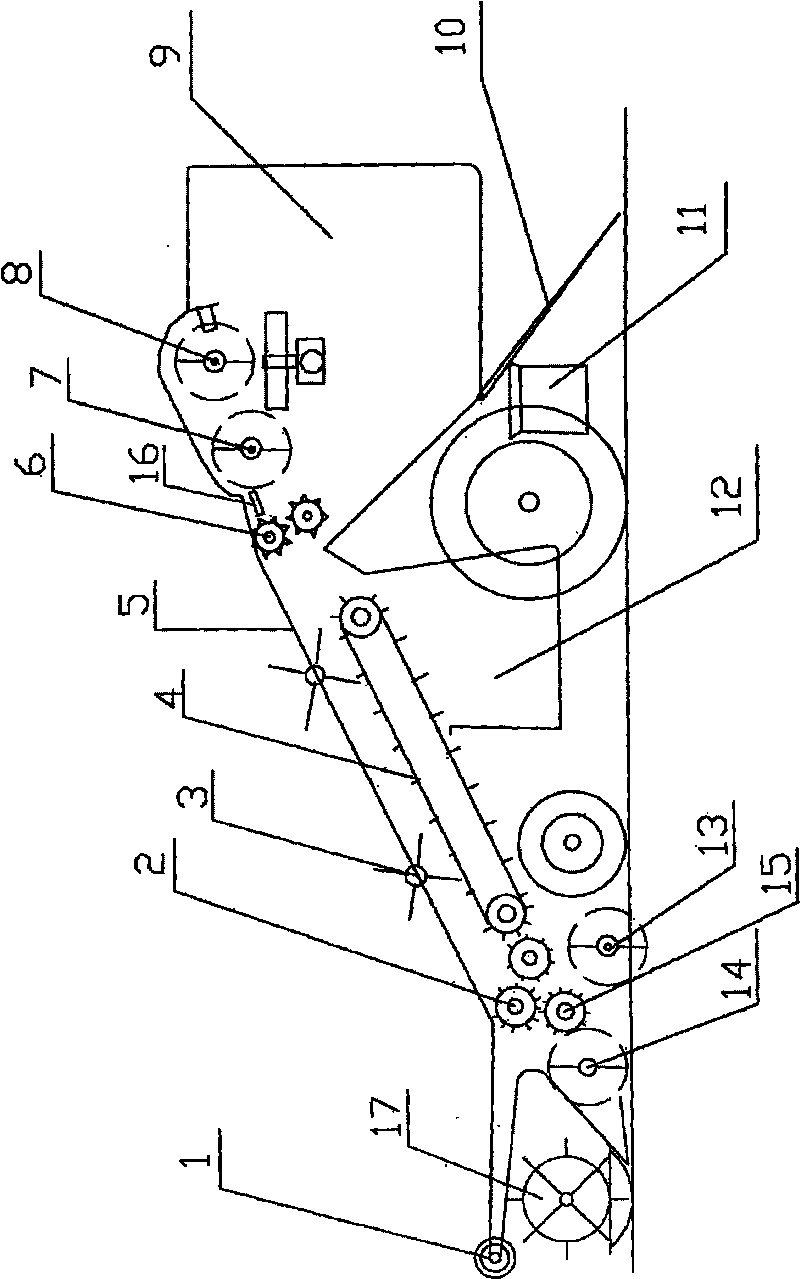

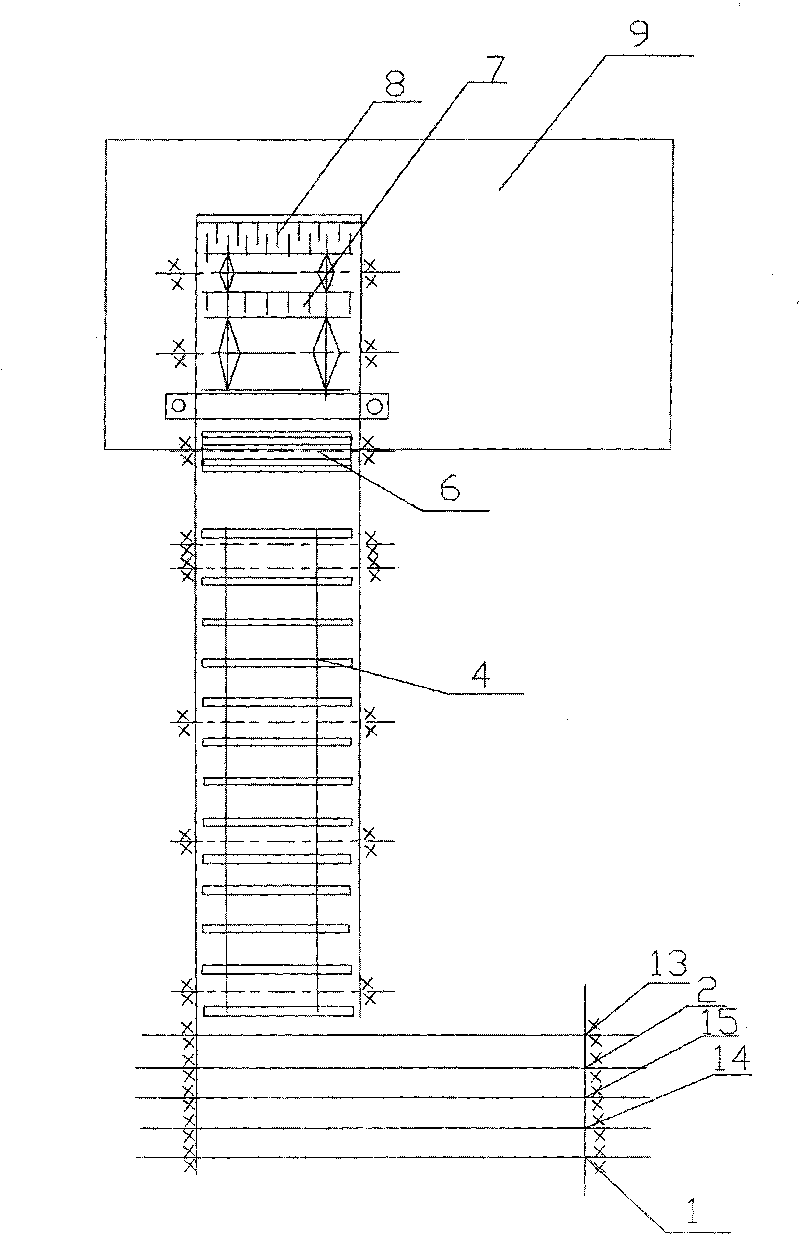

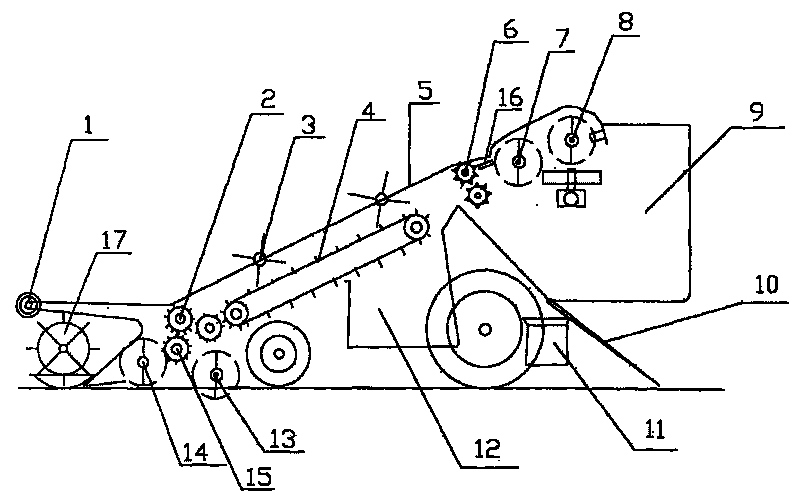

[0012] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a frame 5, in which a feeding device and a crushing device are arranged, and the front end of the frame 5 is provided with a stalk cutting rotary knife 14 for cutting stalks, and the feeding device includes an upper feeding rod 2 that turns in the opposite direction. and the following feeding rod 15, a certain gap is arranged between the upper feeding rod 2 and the lower feeding rod 15, and a transmission chain 4 is arranged on the upper right of the gap between the two feeding rods, and the upper end of the transmission chain 4 and the frame 5 There is a certain distance, the end of the conveyor chain 4 is provided with a crushing device, and the lower end of the crushing device is provided with a collecting device 9 . The right side of the lower feeding stick 15 is provided with a second lower feeding stick; the upper part of the frame 5 is provided with a straw ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com