Ramie combine harvester

A combine harvester and ramie technology, applied in the direction of harvesters, cutters, crop processors, etc., can solve the problems of single-development machinery for peeling or harvesting hemp, low work efficiency of manual harvesting, poor quality of hemp peeling, etc., and achieve improvement Soil physical and chemical properties, cost saving, pollution reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

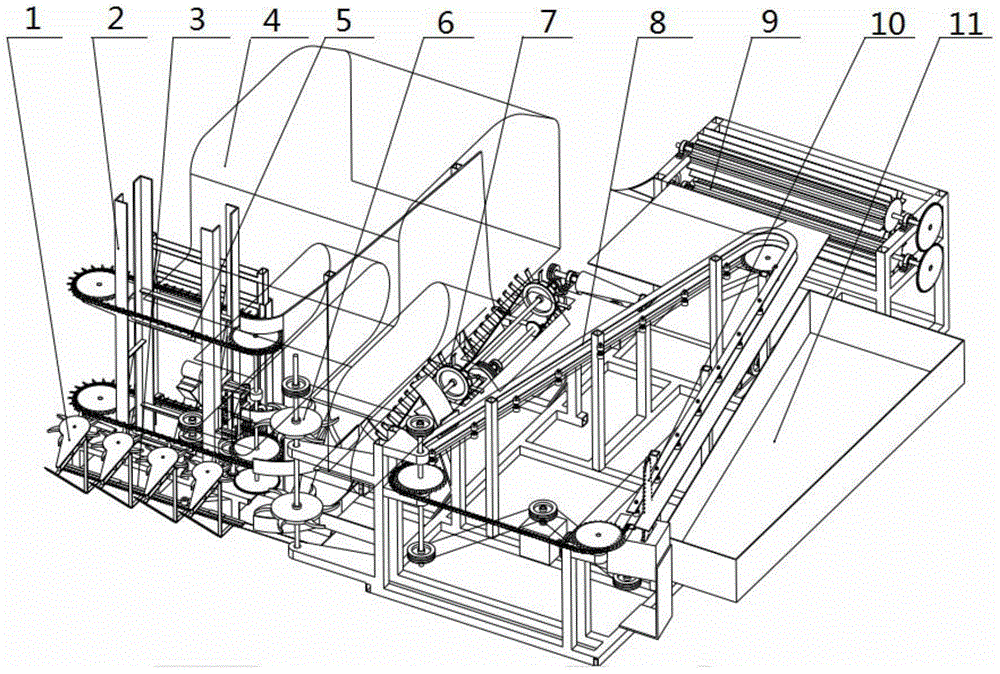

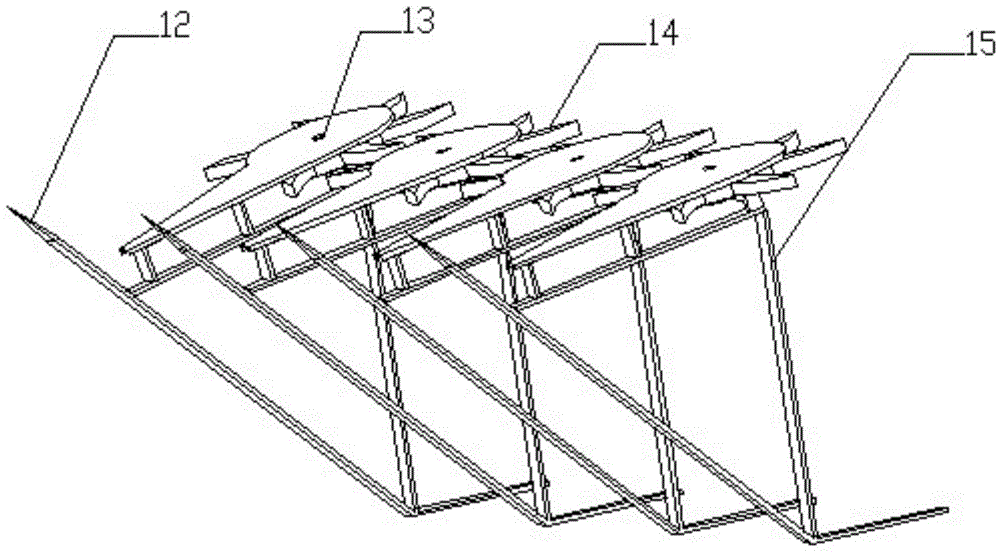

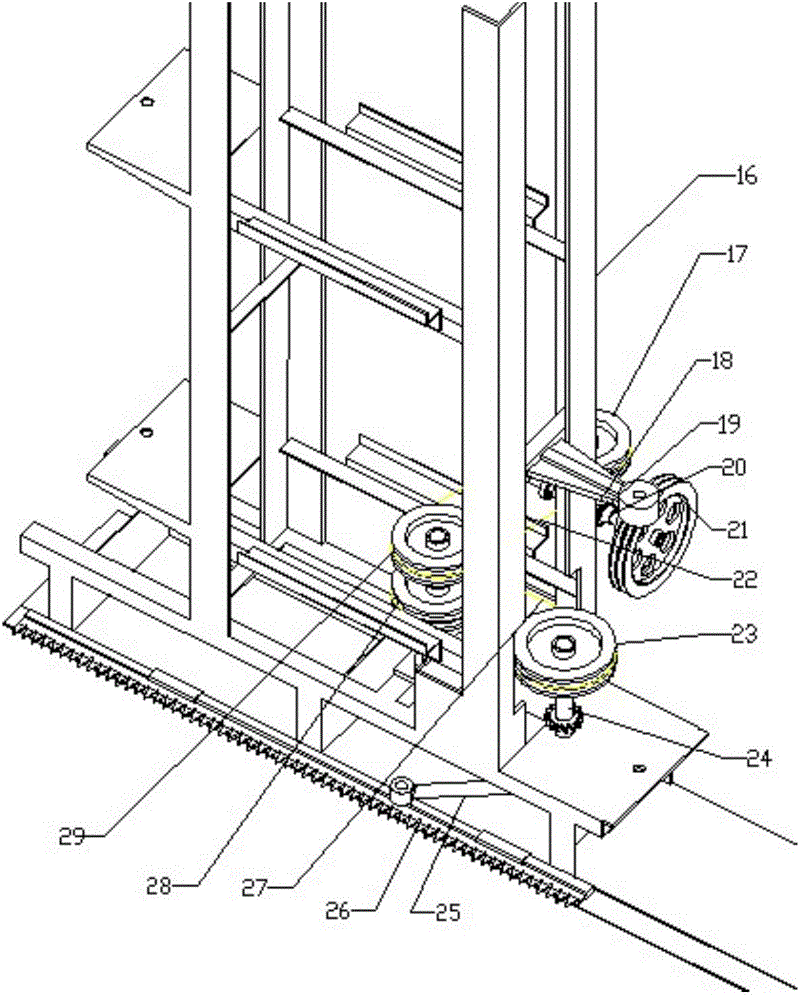

[0031] The present invention is a device integrating harvesting and peeling, and its structure is as follows: figure 1Shown: Including hemp pulling device 1, hemp cutting mechanism 3, traveling mechanism 4, horizontal conveying device 5, hemp turning device 6, hemp separating conveying device 7, double-drum hemp peeling mechanism 9, cutting hemp device arranged in sequence according to the technological process Device 10, clamping unit and finished product collecting box unit. It is characterized in that: the hemp pulling device unit, the hemp cutting mechanism unit, the horizontal transport unit, and the hemp turning device unit are fixed on the bracket to form a harvesting platform, and the harvesting platform and the walking mechanism are combined to complete the harvesting operation; the hemp separating and conveying unit, the tightening unit , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com