High-purity fluorine-containing organophosphorus flame retardant and preparation method thereof

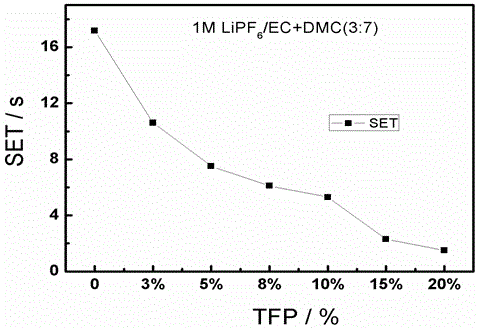

A technology of organic phosphorus and flame retardants, which is applied in the field of preparation of high-purity fluorine-containing organic phosphorus flame retardants, can solve the problems of flame retardant, thermal breakdown battery, non-flammability, etc. explosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

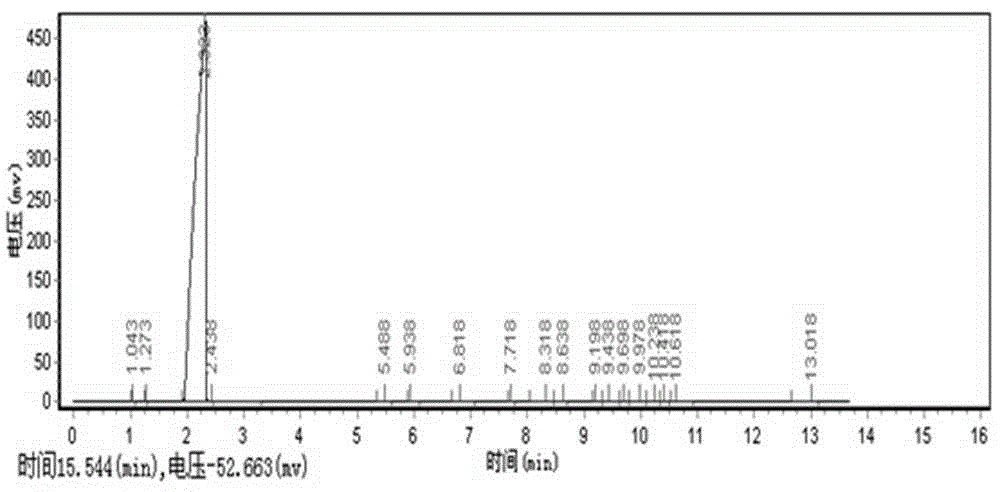

Embodiment 1

[0039] (1) Preparation of trifluoroethoxy phosphate: Add 91.5ml (1mol) of phosphorus oxychloride into a four-neck flask equipped with stirring, condensing device, temperature probe and constant pressure dropping funnel, and the temperature is controlled at 15°C. Add 9.1g (2%.wt) lithium chloride as a catalyst, and slowly add 100g (1mol) trifluoroethanol dropwise through a constant pressure dropping funnel, add dropwise at this temperature, reflux for 2 hours, and absorb the resulting Hydrogen chloride gas; continue to slowly add 200g (2mol) trifluoroethanol dropwise through the constant pressure dropping funnel, the temperature is controlled at 75°C, add dropwise and reflux at this temperature for 9 hours, and absorb the hydrogen chloride gas produced by dilute alkali solution throughout the reaction; low temperature Distilled under reduced pressure for 2h, removed unreacted phosphorus oxychloride and recovered part of trifluoroethanol, suction filtered the remaining solid-liquid...

Embodiment 2

[0042] (1) Preparation of trifluoroethoxy phosphate: Add 91.5ml (1mol) of phosphorus oxychloride into a four-neck flask equipped with stirring, condensing device, temperature probe and constant pressure dropping funnel, and the temperature is controlled at 10°C. Add 26.1g (4%.wt) zinc chloride as a catalyst, and slowly add 100g (1mol) trifluoroethanol dropwise through a constant pressure dropping funnel, add dropwise at this temperature, reflux for 3 hours, and absorb the resulting Hydrogen chloride gas; continue to slowly add 400g (4mol) trifluoroethanol dropwise through the constant pressure dropping funnel, the temperature is controlled at 85°C, add dropwise and reflux at this temperature for 12 hours, and absorb the generated hydrogen chloride gas with dilute lye throughout the reaction; low temperature Distilled under reduced pressure for 3h, removed unreacted phosphorus oxychloride and recovered part of trifluoroethanol, suction filtered the remaining solid-liquid mixture...

Embodiment 3

[0045] (1) Preparation of trifluoroethoxy phosphate: Add 91.5ml (1mol) of phosphorus oxychloride into a four-neck flask equipped with stirring, condensing device, temperature probe and constant pressure dropping funnel, and the temperature is controlled at 15°C. Add 11.1g (2%.wt) lithium chloride as a catalyst, and slowly add 100g (1mol) trifluoroethanol dropwise through a constant pressure dropping funnel, add dropwise at this temperature, reflux for 2 hours, and absorb the resulting Hydrogen chloride gas; continue to slowly add 300g (3mol) trifluoroethanol dropwise through the constant pressure dropping funnel, the temperature is controlled at 80°C, add dropwise at this temperature, and reflux for 10 hours, and absorb the hydrogen chloride gas produced by dilute alkali solution throughout the reaction; low temperature Distill under reduced pressure for 2.5h, remove unreacted phosphorus oxychloride and reclaim part of trifluoroethanol, suction filter the remaining solid-liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com