Pressure-adjusting conveying friction double roll device

A friction pair and pressure technology, which is used in transportation and packaging, thin material handling, and coiling of strips, etc., can solve the problems of inability to drive material feed and quickly separate rollers, and achieve convenient adjustment and operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described now in conjunction with the preferred implementation examples of the accompanying drawings.

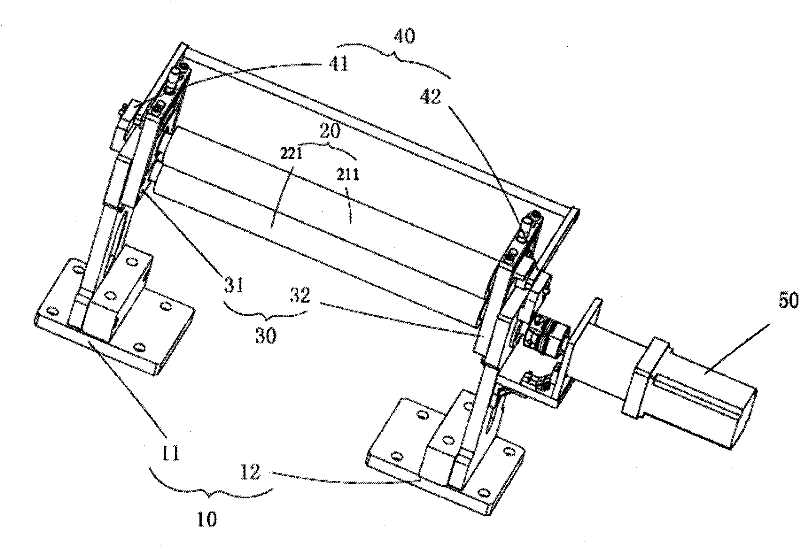

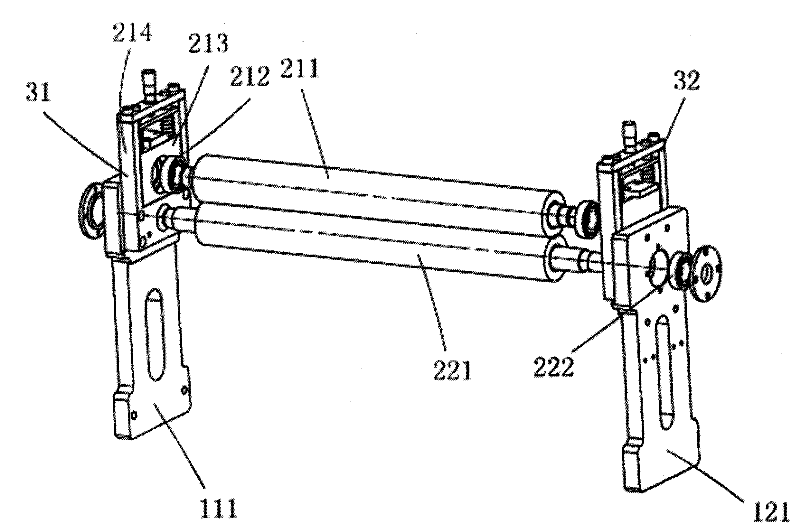

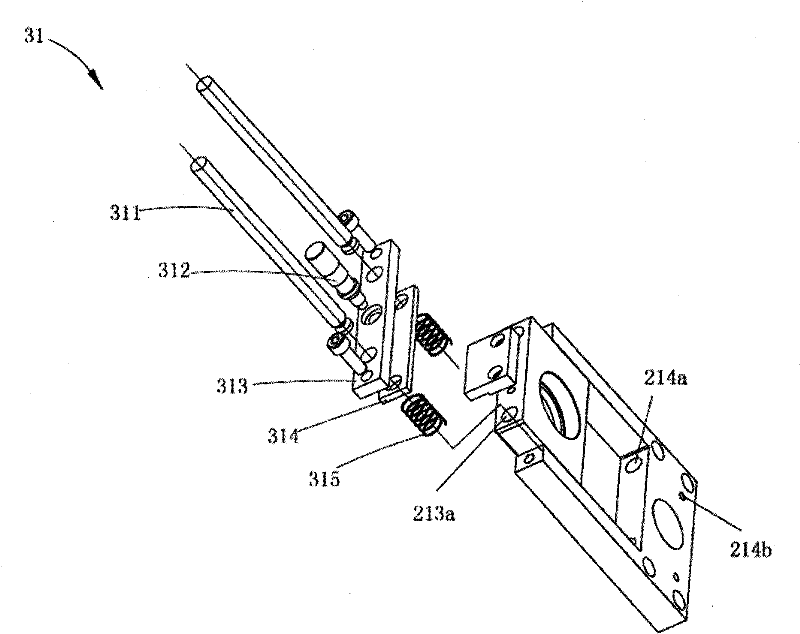

[0016] see figure 1 , The preferred embodiment of the present invention mainly includes a support assembly 10 , a friction pair roller assembly 20 , a pair of roller pressure adjustment assemblies 30 , a pair of roller separation assemblies 40 , and a pair of roller drive assemblies 50 . The support assembly 10 provides support for the device and the interface connected with the equipment; the drive assembly 50 provides rotational power for the roller assembly 20 to drive the feeding of the film substrate; the pressure adjustment assembly 30 can evenly adjust the drive roller 221 in the roller assembly 20 and the pressure between the floating roller 211 to adapt to the conveying force required for feeding different substrates; the roller separation assembly 40 can assist in quickly separating the driving roller 221 and the floating roller 211 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com