Environment-friendly printing platen adhesive emulsion and preparation method thereof

An adhesive and environment-friendly technology, applied in adhesive types, ester copolymer adhesives, dyeing methods, etc., can solve the problems of environmental pollution, inability to use one scrape coating for multiple times, poor water resistance, etc., and achieve Accurate printing color registration, good cohesion and stickiness, and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

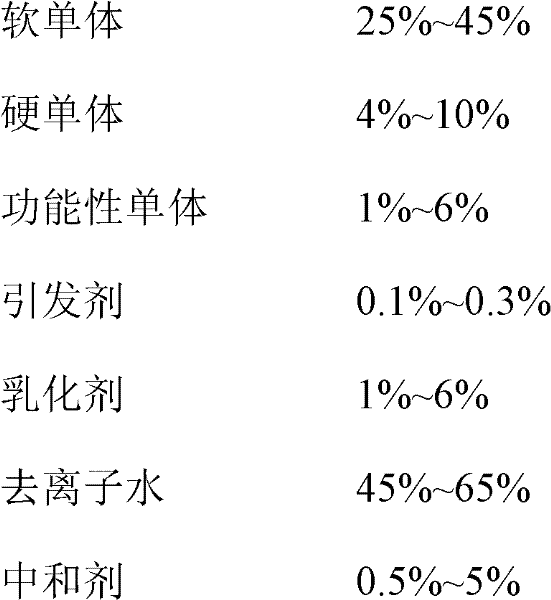

Method used

Image

Examples

Embodiment 1

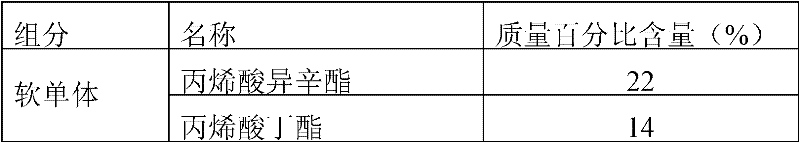

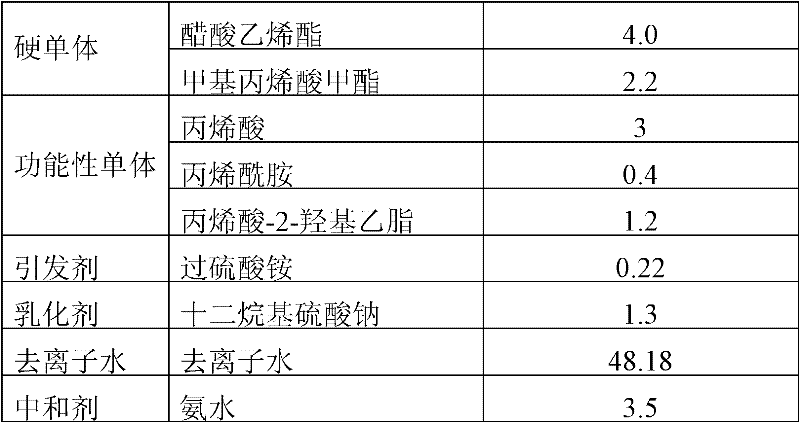

[0026]

[0027]

[0028] The preparation method of the present embodiment comprises the following steps:

[0029] A. Dissolve emulsifier sodium lauryl sulfate in 30.0% deionized water, stir, add soft monomer, hard monomer, functional monomer, stir to obtain pre-emulsion;

[0030] B, ammonium persulfate is dissolved and made into initiator solution with 3% deionized water for stand-by;

[0031] C, add surplus deionized water in the reactor, get 5% of the pre-emulsion prepared in step A and add in the reactor, be warming up to 80 ℃, add 27% of the initiator solution that makes in the step B, React for 20 minutes; start to add the remaining amount of pre-emulsion and the remaining amount of initiator solution dropwise, and the dropwise addition is completed in 4 hours. After all the dropping is completed, the temperature is raised to 86°C for 2 hours, and the temperature is lowered to below 40°C. Add ammonia water to neutralize After the pH value was 7.0-8.0, the material ...

Embodiment 2

[0033]

[0034]

[0035] The preparation method of the present embodiment comprises the following steps:

[0036] A. Dissolve emulsifier sodium lauryl sulfate in 36.0% deionized water, stir, add soft monomer, hard monomer, functional monomer, stir to obtain pre-emulsion;

[0037] B, potassium peroxide is dissolved and made into initiator solution with 3% deionized water for stand-by;

[0038] C, add surplus deionized water in the reactor, get 5% of the pre-emulsion prepared in step A and add in the reactor, be warming up to 80 ℃, add 22% of the initiator solution that makes in the step B, React for 25 minutes; start to add the remaining amount of pre-emulsion and the remaining amount of initiator solution dropwise, and the dropwise addition is completed in 4 hours. After all the dropwise addition is completed, the temperature is raised to 88°C and incubated for 1.5 hours, and the temperature is lowered to below 40°C. Add ammonia water to neutralize After the pH value wa...

Embodiment 3

[0040]

[0041]

[0042] The preparation method of the present embodiment comprises the following steps:

[0043] A. Dissolve emulsifier sodium lauryl sulfate in 32.0% deionized water, stir, add soft monomer, hard monomer, functional monomer, stir to obtain pre-emulsion;

[0044] B, potassium peroxide is dissolved and made into initiator solution with 3% deionized water for stand-by;

[0045] C, add surplus deionized water in the reactor, get 5% of the pre-emulsion prepared in step A and add in the reactor, be warming up to 80 ℃, add 21% of the initiator solution that makes in the step B, React for 15 minutes; start to add the remaining amount of pre-emulsion and the remaining amount of initiator solution dropwise, and the dropwise addition is completed in 4 hours. After all the dropwise addition is completed, the temperature is raised to 88°C and incubated for 1.5 hours, and the temperature is lowered to below 40°C. Add ammonia water to neutralize After the pH value wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com