Method for producing multicolor composite slub or satin color yarn series, shell fabric and yarn

A kind of colorful and production method technology, applied in the field of yarn and fabric, can solve the problems of shortening hairiness, increasing yarn strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Development and design of colorful composite bamboo series textiles:

[0025] 1. Colorful composite slub yarn

[0026] The research and design are: viscose cotton two-component red, blue and white three-color composite slub yarn (hereinafter referred to as "cotton viscose three-color slub yarn") 9.8tex; slub length 55mm: 65mm = 1:2; slub ratio: 1.8; base yarn length: 600, 450, 250, 400, 290, 300, 380, 450, 700, 210, 390, 550, 680, 270, 320, 800, 480, 550, 230, 720, 650, 450, 290, 320, 600, 290, 550, 270, 210, 480, 290, 800. 230, 380, 250, 600, fuzzy law.

[0027] 2. 165㎝ R9.8 / Viscose cotton three-color slub yarn 9.8tex 20 / 1 × R9.8 / Viscose cotton three-color slub yarn 9.8tex 20 / 1 354 / 10cm×346 / 10cm 1 / 1 Three-color bamboo Festival cloth.

[0028] Product trial production:

[0029] 1. Trial production of viscose cotton tricolor slub yarn:

[0030] 1.1 Cotton red and blue two-color fiber (cotton fiber dyeing is provided by the customer to provide a color card for outsou...

Embodiment 2

[0065] Colorful slub cloth

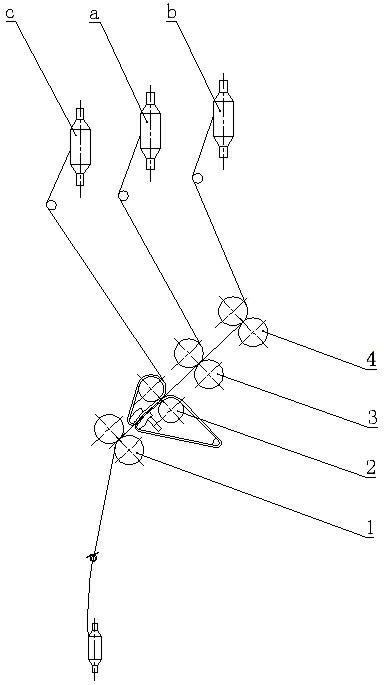

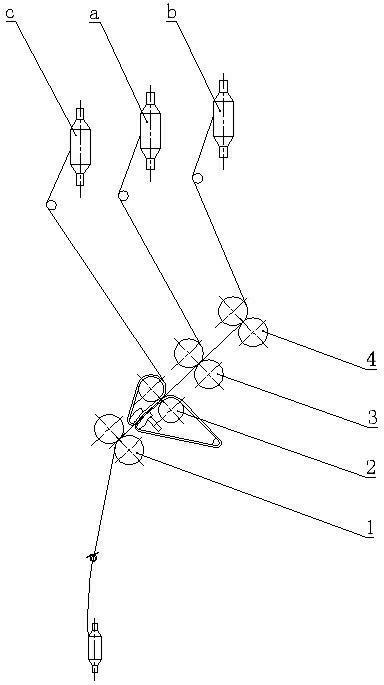

[0066] process flow

[0067] Pass the above yarn through the following machines: ASGA221 (180) batch warping machine, ASGA365C-S double size tank sizing machine, G177 type heald drawing machine, ZAX (N) air jet loom, GA801 type inspection machine Cloth machine, G841 folding machine, A752 packing machine to process the fabric.

[0068] The specific process is as follows:

[0069] 1. Warping process:

[0070] Product warping is uniform in three ways: uniform tension, uniform arrangement, and uniform winding, especially the uniform tension is related to the style characteristics of the quality of the fabric, such as clear texture, and the tension device needs to be finely adjusted. The matching three-color slub yarn has slubs , the tension ring is appropriately reduced to improve the uniformity of tension; at the same time, all yarn channels of the warping machine need to be fully cleaned and deburred to reduce the strength loss and production brea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com