Full-automatic material taking and material feeding sewing machine

A fully automatic sewing machine technology, applied in the direction of sewing machine components, cloth feeding mechanism, sewing equipment, etc., can solve the problems that affect the appearance of cloth keyhole stitches, inaccurate cloth buttonhole positions, and high labor intensity of operators, etc., to achieve strong practicability , machine maintenance is convenient, the effect of structure optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with specific examples.

[0037] The theme of this embodiment is the automatic feeding and feeding buttonhole machine, which automatically fetches and sends the cloth through the sensor to detect the pressure signal. An automatic sewing machine that sews a number of buttonholes to form a plurality of buttonholes at set intervals.

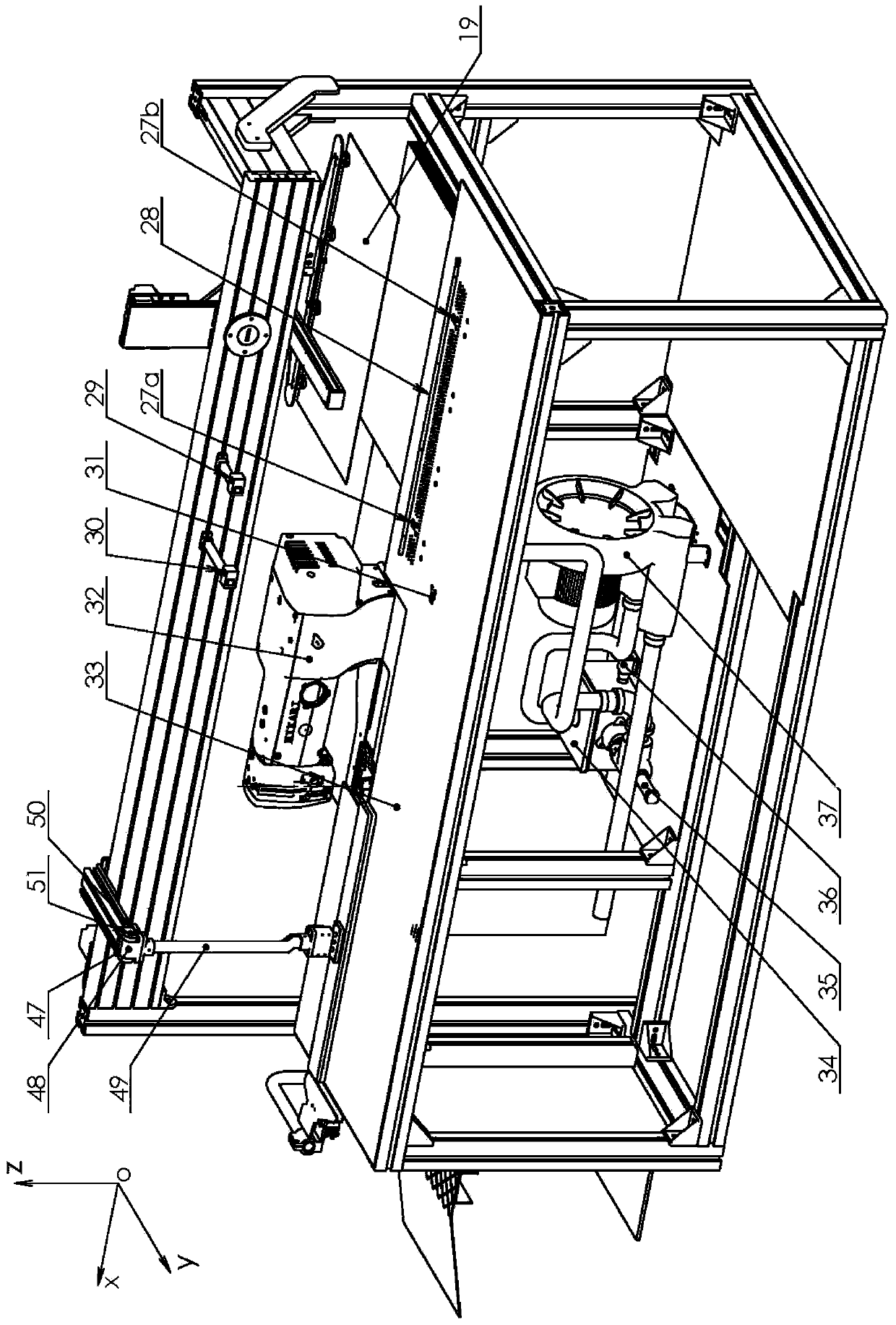

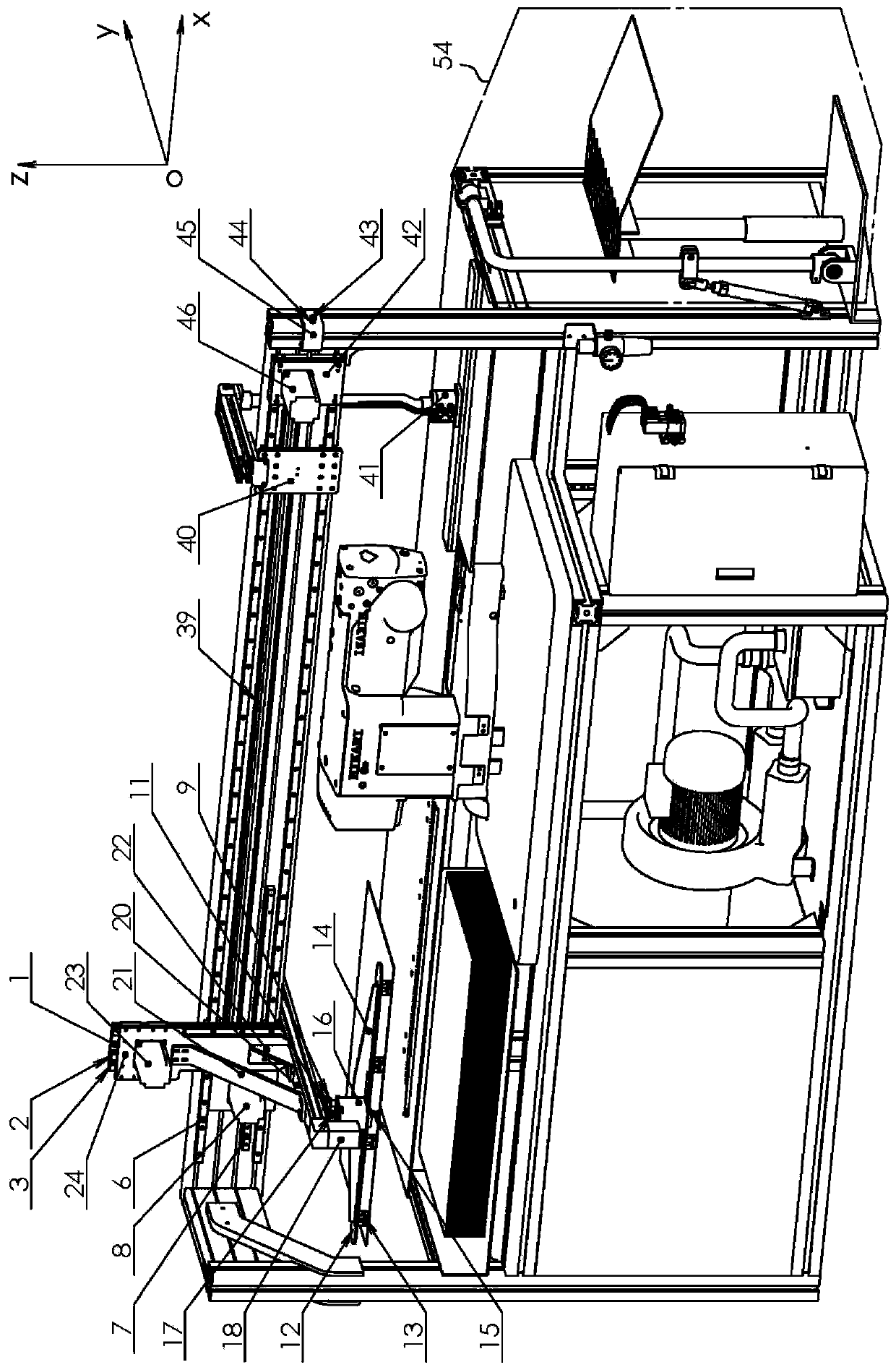

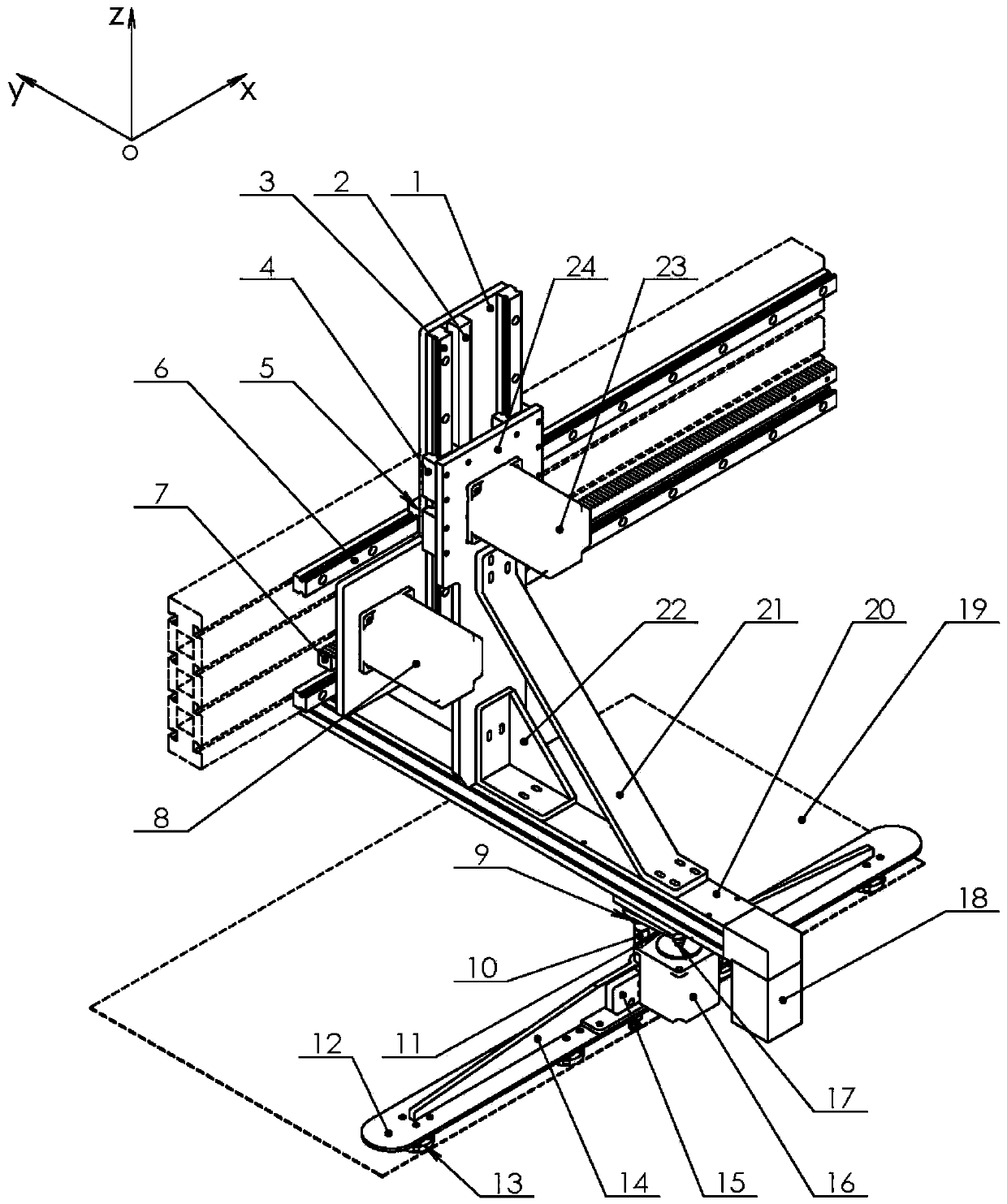

[0038] see image 3 ,6 , the left and right movement direction of the sewing press feeding device is defined as the X axis direction (left and right direction), the up and down movement direction of the cloth picking device is defined as the Z axis (up and down direction), and the X axis direction and the Z axis direction are perpendicular to the two directions The direction of is defined as the Y-axis direction (front-rear direction), and the axial direction of the rotation shaft 10 is defined as the K-axis.

[0039] Such as Figure 1-8 As shown, take the X-direction mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com