Method for preparing super-hydrophobic super-oleophylic cotton

A super-lipophilic and super-hydrophobic technology is applied in the field of preparation of super-hydrophobic and super-oleophilic cotton, which can solve the problems of high cost and high technical requirements, and achieve the effects of low cost, easy availability of raw materials and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

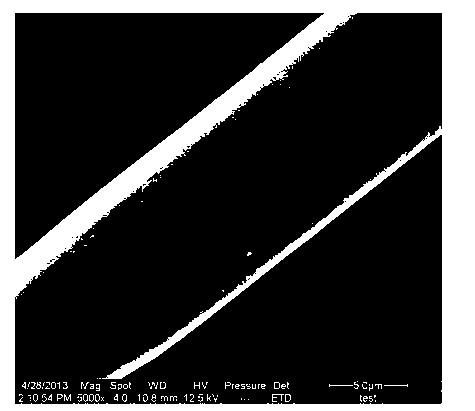

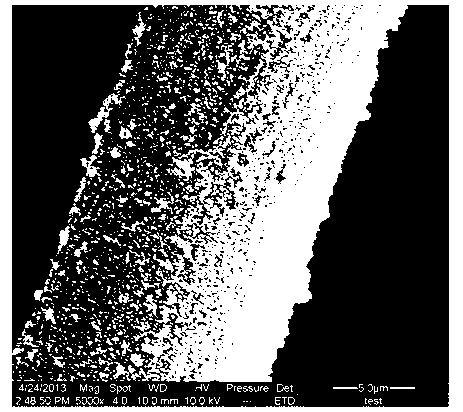

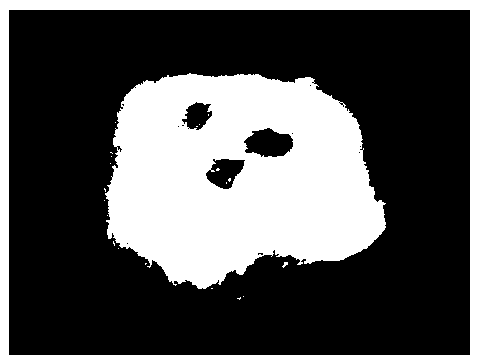

Image

Examples

specific Embodiment approach 1

[0023] Specific embodiment one: the preparation method of super-hydrophobic super-oleophilic cotton in the present embodiment is carried out according to the following steps:

[0024] step one 、 Mix 90mL of absolute ethanol, 10mL of tetraethyl orthosilicate and 10mL of deionized water, then add 5-10mL of ammonia water, and then magnetically stir until uniform at room temperature to obtain SiO 2 Precursor solution;

[0025] Step 2. Mix 100mL absolute ethanol, 1mL~2mL octadecyltrichlorosilane, (OTS) and 0.1mL~0.25mL deionized water, and then stir at room temperature for 2 hours to obtain the OTS modified solution;

[0026] Step 3. Soak the cotton in NaOH aqueous solution with a concentration of 2%~5% by mass, cover with a lid, boil on low heat for 5~10 minutes, then take out the cotton, rinse with water and rub at the same time until the pH of the washing solution is reached. The value is 7.0, dry naturally;

[0027] Step 4, soak the cotton treated in step 3 in the SiO prepar...

specific Embodiment approach 2

[0029] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the NaOH aqueous solution described in step three is prepared according to the following steps : Weigh 2~5g of NaOH solid, dissolve in 100ml of deionized water, cool to room temperature, and set aside. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0030] Specific embodiment three: this embodiment and specific embodiment one or two are: the soaking time described in step four is 1-1.5 hours. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com