Continuous microwave vacuum drying and sterilizing processing device

A technology of microwave vacuum drying and processing equipment, applied in progressive dryers, lighting and heating equipment, drying solid materials, etc., can solve the problems of inconsistent product moisture content and affecting product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

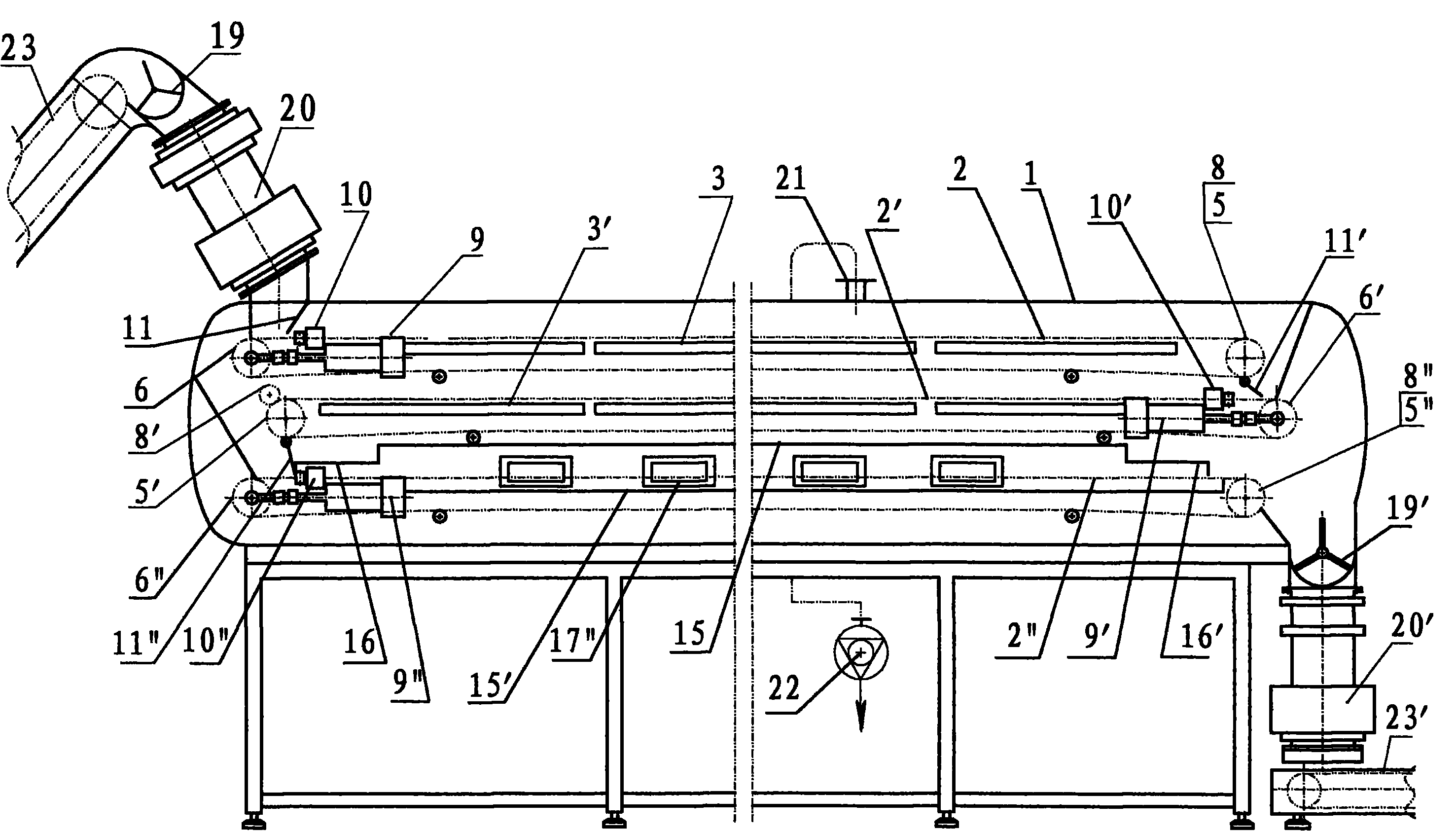

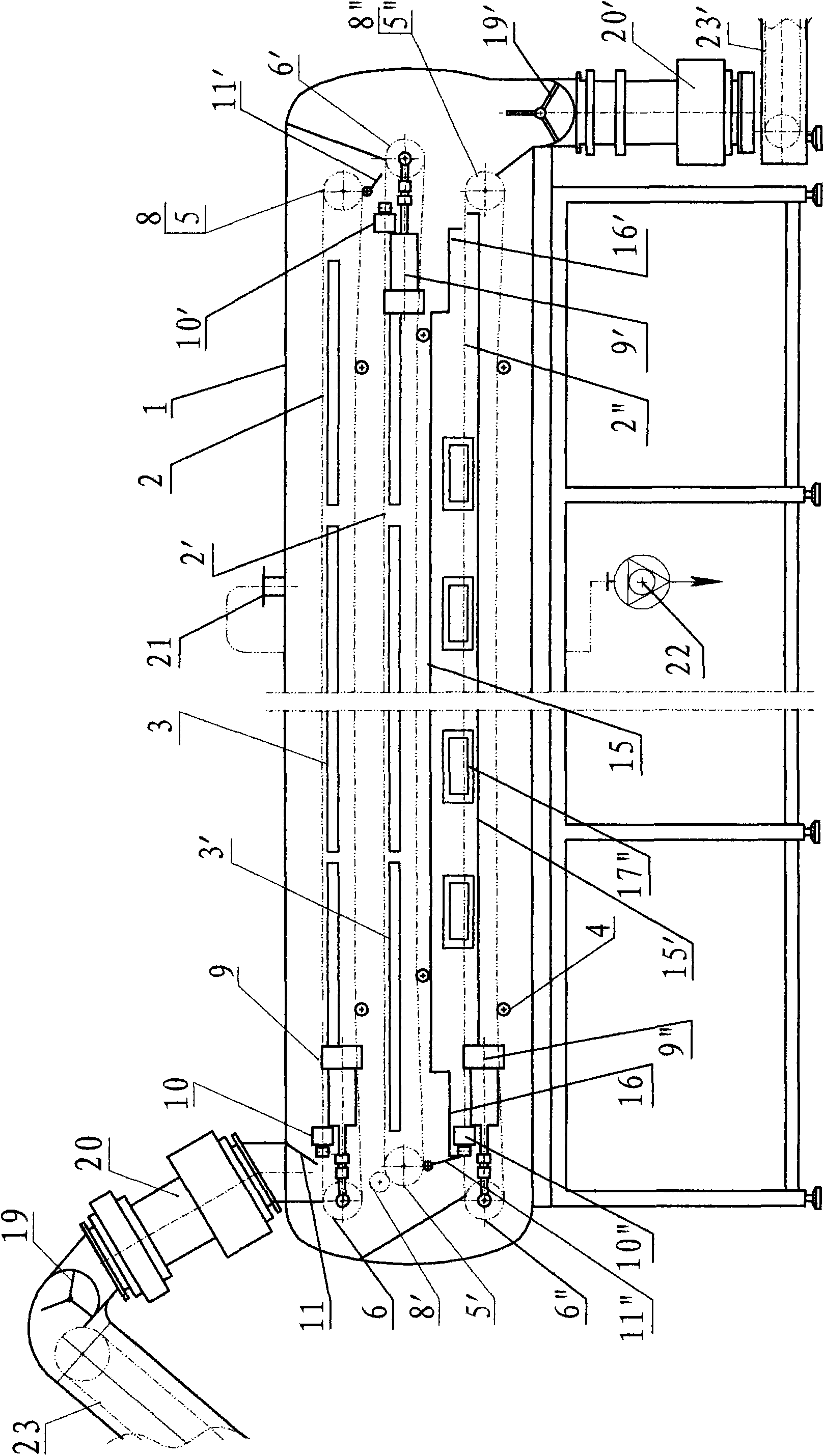

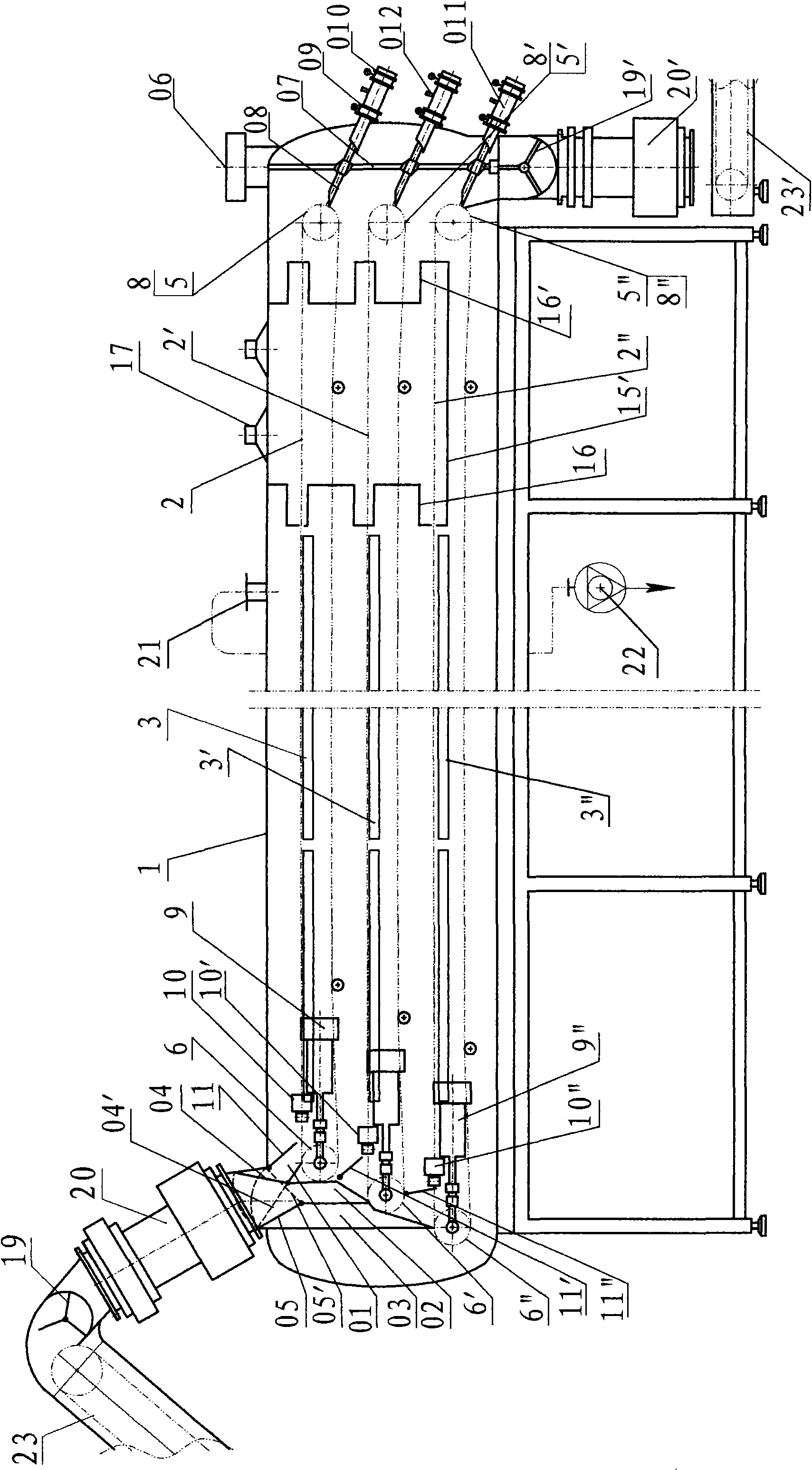

[0027] Further describe structure and working process of the present invention below in conjunction with accompanying drawing:

[0028]As shown in Figure 1: The continuous microwave vacuum drying and sterilization processing equipment for processing solid materials in the present invention is mainly equipped with material conveyor belts, quantitative supply devices, sealing devices for feeding and discharging materials, vacuum chambers, uniform material devices, and heating medium heating plates , heat medium heating device, microwave magnetic control device, microwave choke device, microwave upper and lower baffles, vacuum system and heating device, characterized in that: it is mainly provided with feeding and discharging conveyor belts (23, 23'), Quantitative supply device (19, 19'), material inlet and outlet sealing device (20, 20'), vacuum chamber (1) is composed, the vacuum chamber (1) can be set to circular or rectangular, is provided with in the vacuum chamber (1) Homog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com