Prefabricated wallboard supporting device for house building

A technology of prefabricated wall panels and supporting devices, which is applied in construction, building structure, processing of building materials, etc., can solve the problems of inability to adjust the supporting position and supporting angle, and inconvenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

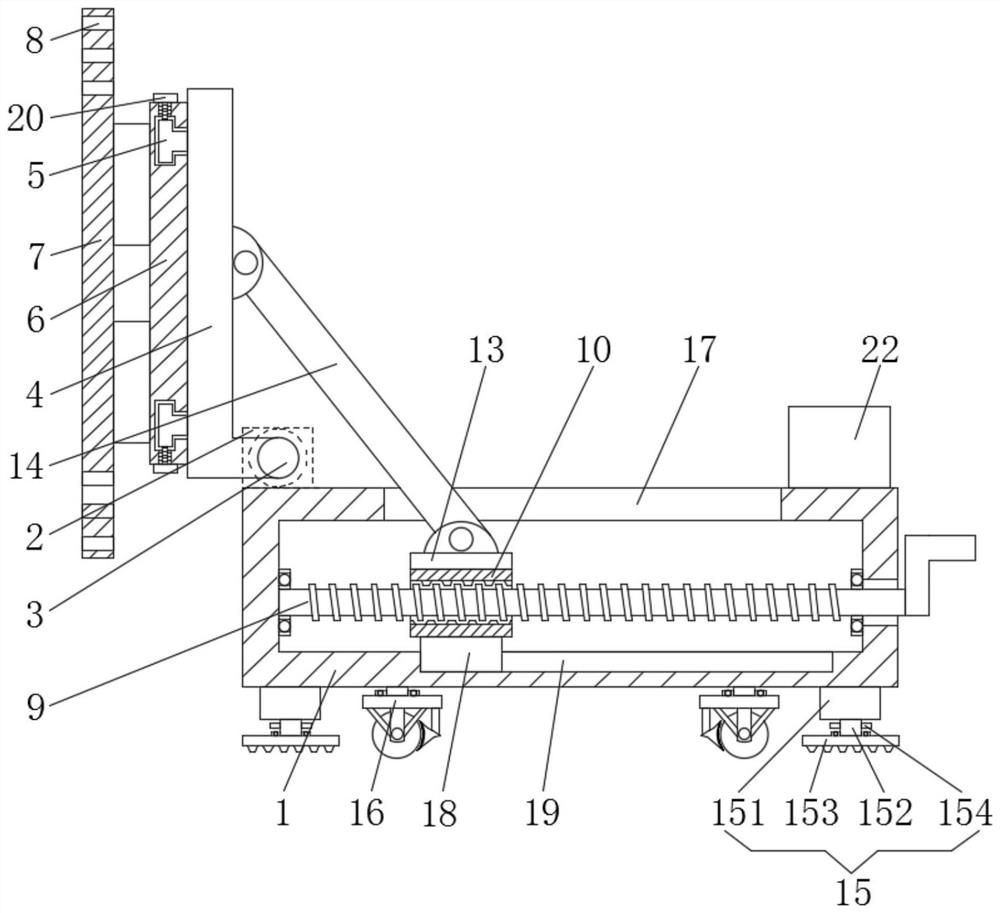

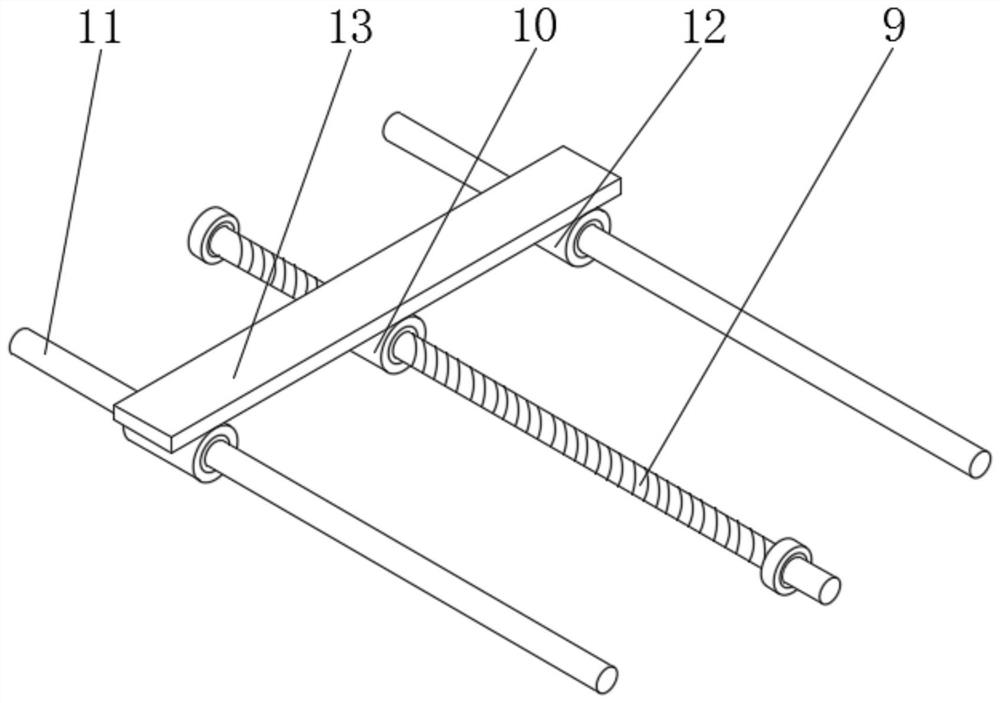

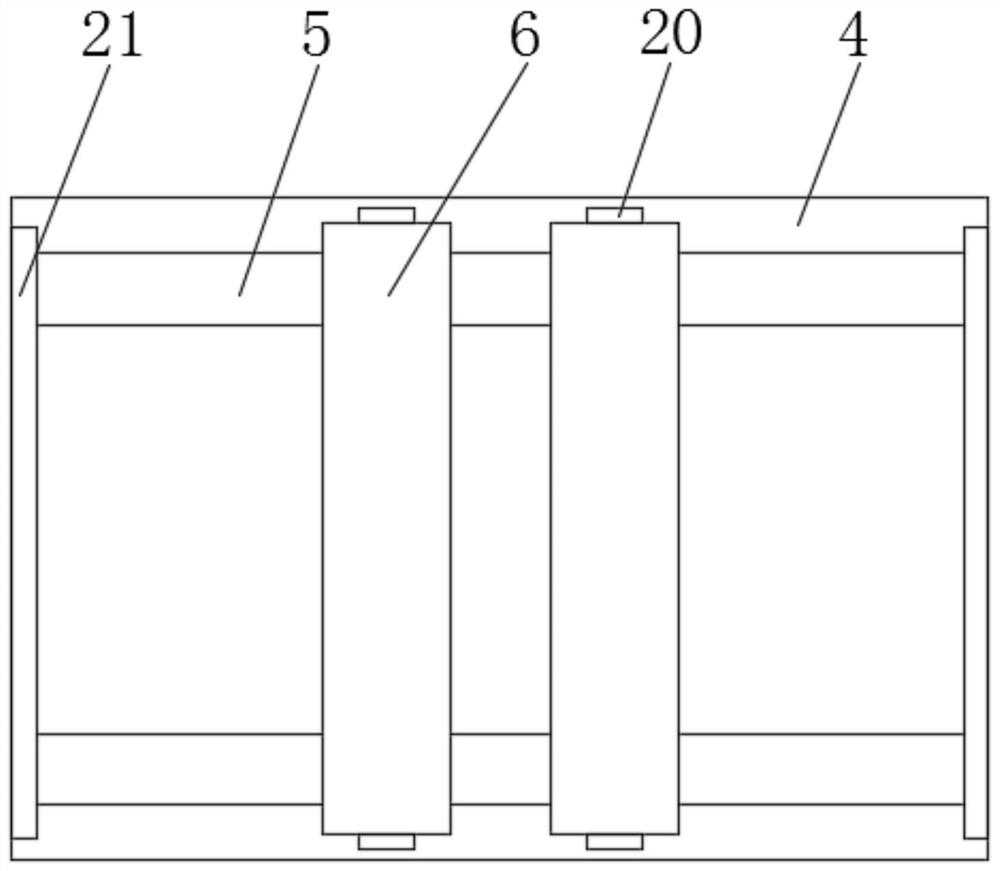

[0029] see Figure 1-5 , a prefabricated wall panel support device for house construction, comprising a moving box 1, a positioning plate 2 is fixedly connected to the front and rear positions on the left side of the top of the moving box 1, and a rotating shaft 3 is connected to the opposite side of the two positioning plates 2 through bearing rotation , the left side of the rotating shaft 3 is fixedly connected with an L-shaped plate 4, the upper and lower positions on the left side of the L-shaped plate 4 are fixedly connected with a slide rail 5, the front and rear sides of the upper and lower two slide rails 5 are slidably connected with a slide plate 6, and the slide plate 6 The left side of the mobile box 1 is fixedly connected with a support plate 7 through a connecting block, and the top and bottom of the left side of the support plate 7 are uniformly provided with mounting holes 8, and the left and right sides of the inner cavity of the moving box 1 are connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com