Production process for concave-convex type folding dust-catching cloth bag framework

A manufacturing process and skeleton technology, which is applied in the field of manufacturing technology of concave-convex folding dust bag skeleton, can solve the problems of complicated and difficult skeleton manufacturing process, difficult product assembly and installation, and non-uniform standards of parts, so as to shorten the assembly time and increase the degree of automation The effect of improving and shortening the manufacturing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

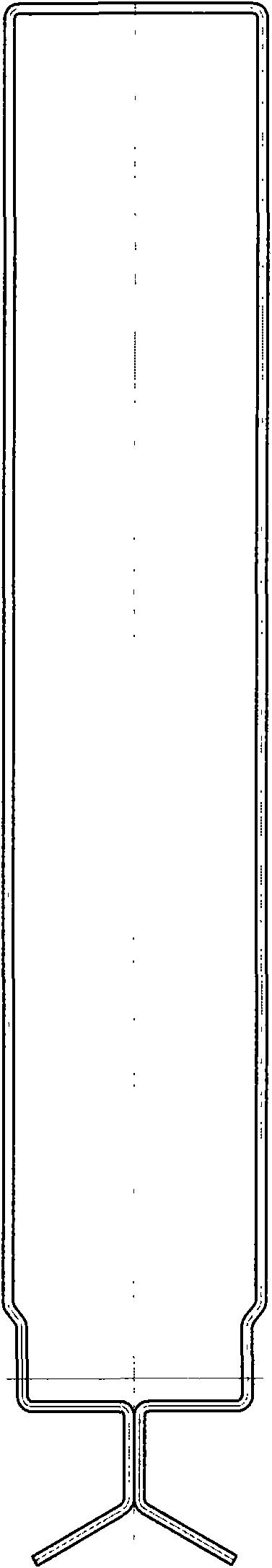

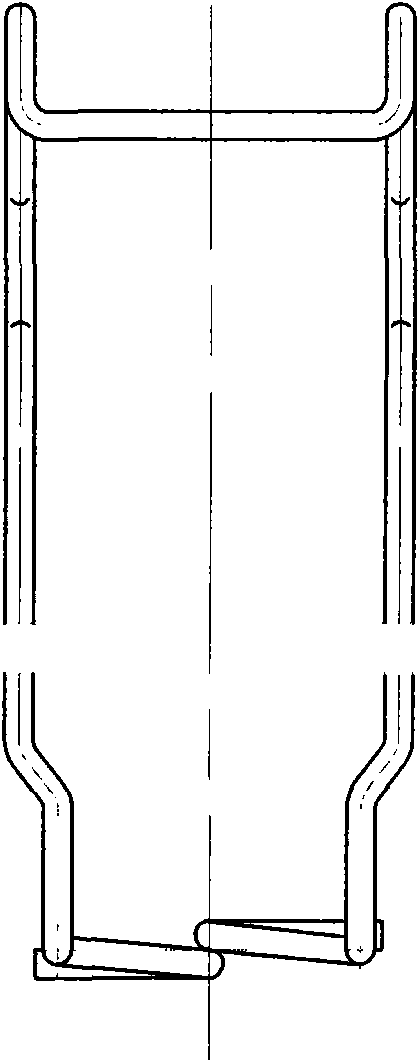

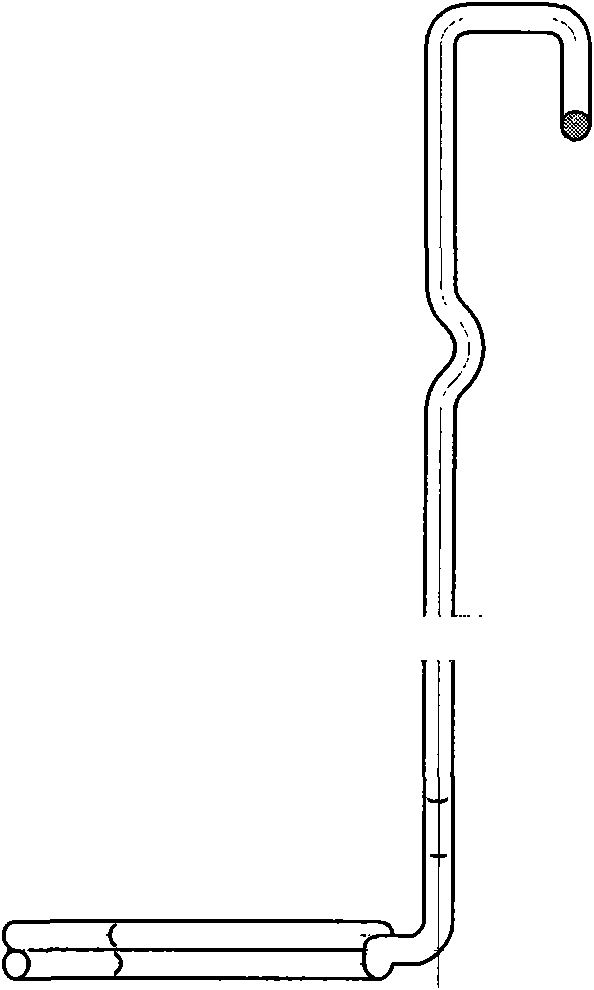

[0047] A manufacturing process for the skeleton of a concave-convex folding dust bag. In order to facilitate a clear description of the production process, the structure of the plane forming machine, 90-degree forming machine and upper skeleton joint forming machine used in the processing is firstly described here:

[0048] 1. Plane forming machine

[0049] The plane forming machine includes a body 7 and a door-pressing mechanism and a two-end forming mechanism installed on the body, wherein:

[0050] (1) Door-pressing mechanism: a positioning tool 1 and 8 are respectively fixed on the two ends of the upper part of the front end of the body, a block 2 is fixed on the body between the two positioning tools, and a vertical block is arranged in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com