Residual film picking roller with film picking teeth

A technology for picking up residual film and picking film teeth, which is applied in the field of agricultural machinery, can solve problems such as the difficulty of one-time forming and welding, insufficient radial rigidity of the roller, and poor craftsmanship of the swing arm design, so as to reduce labor cost and labor difficulty and ensure performance safety. Reliable, rigidity-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

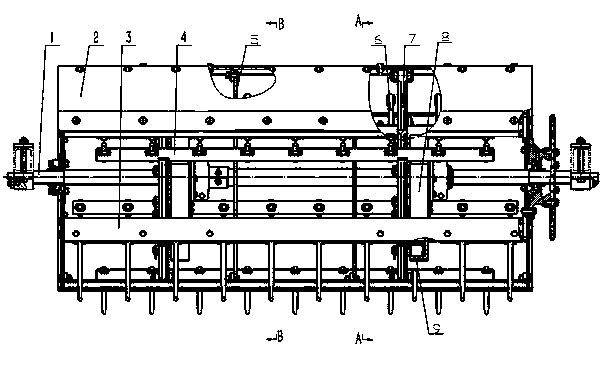

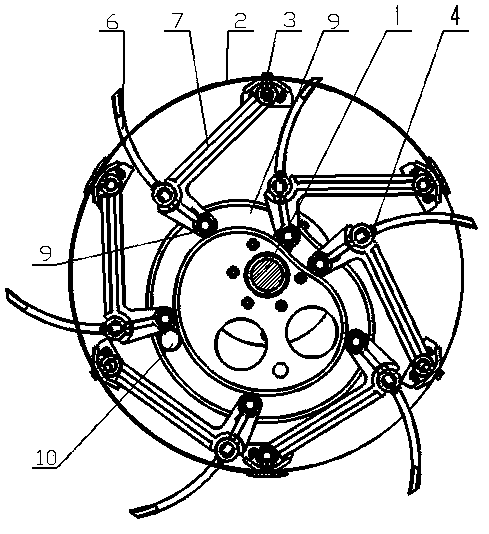

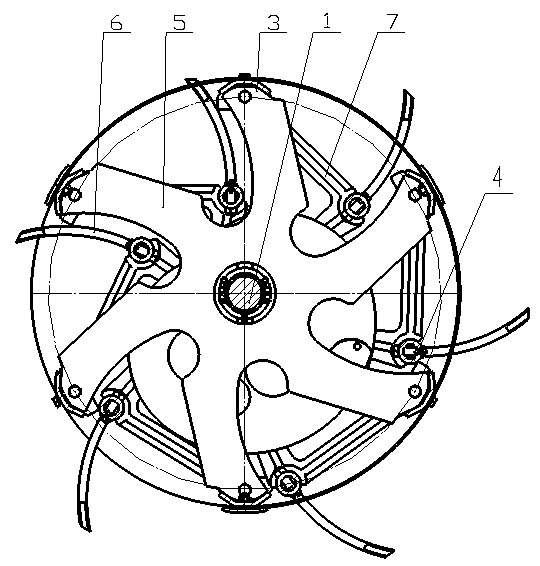

[0010] A kind of residual film picking roller with film picking teeth, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 As shown, it includes the cam plate (8) fixed on the drum shaft (1), and the film-picking tooth beams (4) parallel to the drum shaft (1) are evenly distributed around the cam disc (8). The film-picking tooth (6) on the tooth beam (4) is matched with the through hole on the wall of the drum. It is characterized in that: the film-picking tooth beam (4) is fixedly connected to the inflection point of the crank arm (7), and the crank arm ( 7) The rolling ring (9) provided at the end of the short arm matches the groove on the cam plate (8), and the end of the long arm of the crank arm (7) is hinged on the axial frame (3) of the roller. The radial support frame (5) of the drum wall is uniformly arranged inside the drum (2), the roller ring replacement window (10) is arranged on the bottom surface of the cam disc (8), and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com