Blocking site detection locator of electric wire protective sleeve

A protection tube and locator technology, which is applied in electric/magnetic exploration, radio wave measurement systems, instruments, etc., can solve problems such as low sensitivity, flattening, and breakage of the protection tube, and achieve labor difficulty and strength reduction, sensitivity and Improved accuracy and smaller damage area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

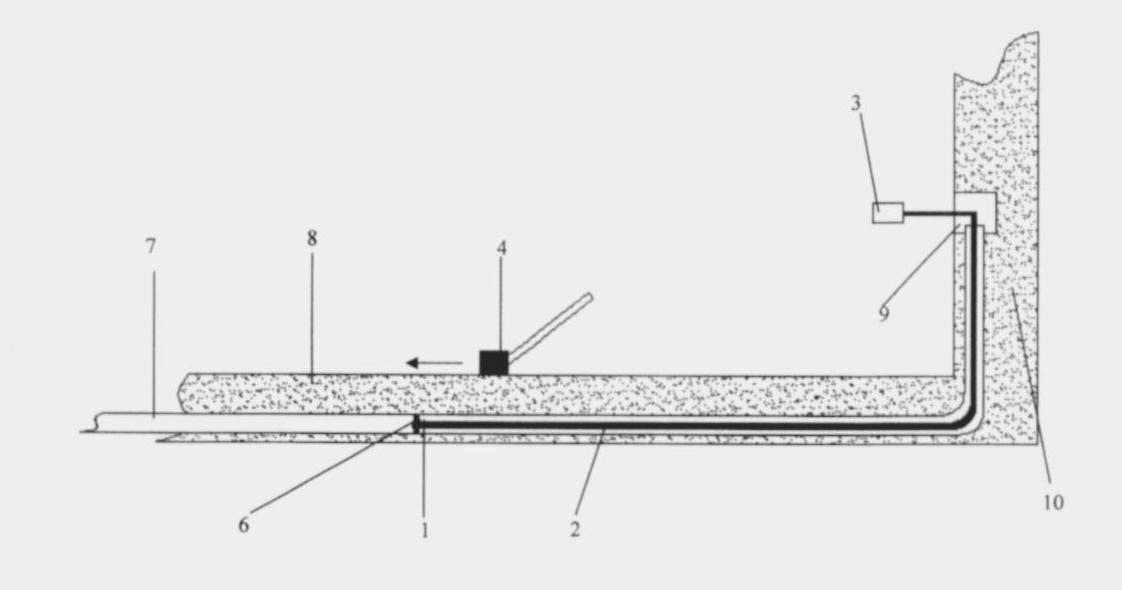

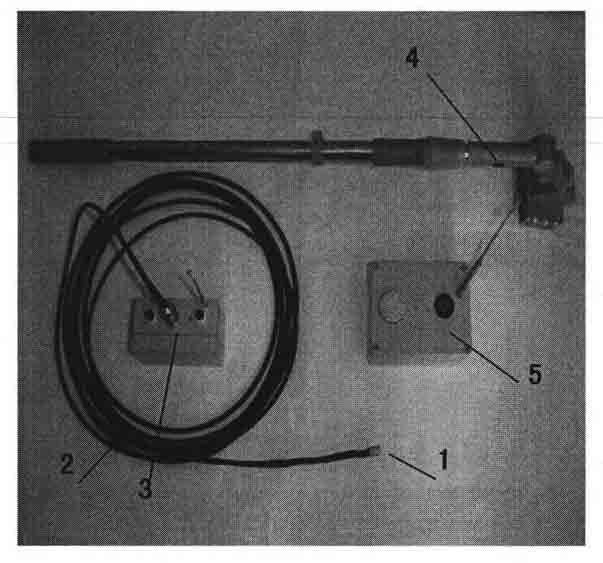

[0018] First, put the magnetic induction device (1) and the detection cable (2) into the wire protection tube until the magnetic induction device (1) reaches the blocking position; connect the end of the detection cable (2) with the trigger device (3); open the trigger device (3 ) and the power switch of the acousto-optic alarm device (5); the detection and positioning device (4) that can generate stable magnetism when moving along the direction of the wire protection tube on the floor or wall; when the magnetic induction device (1) senses the detection and positioning device ( 4) When the magnetic field is emitted, the acousto-optic alarm device (5) starts to send an audible-visual alarm signal, and writes down the boundary of its alarm area (about 100mm in diameter), and the center point of this area is exactly the accurate blockage position of the protective tube.

[0019] When detecting and positioning, it is necessary to ensure that the magnetic induction device (1) reache...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com