Automatic adhesive sticking machine of flexible packaged lithium battery

A lithium battery and glue sticking machine technology, applied in the field of automation, can solve the problems of high production cost of enterprises, difficulty in manual sticking and sticking at the same position, high labor intensity, etc., so as to improve production efficiency, improve the quality of sticking batteries, reduce The effect of labor difficulty and intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

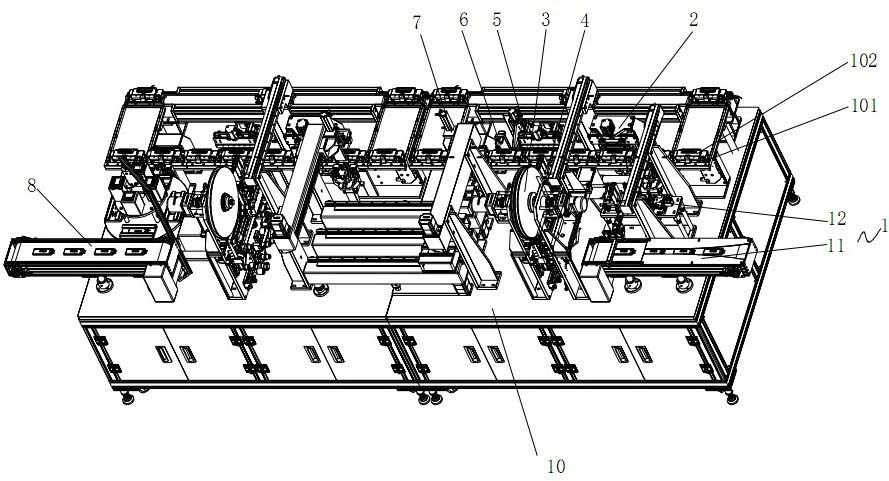

[0028] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below with reference to the drawings and embodiments.

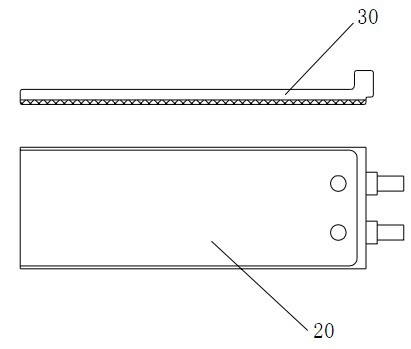

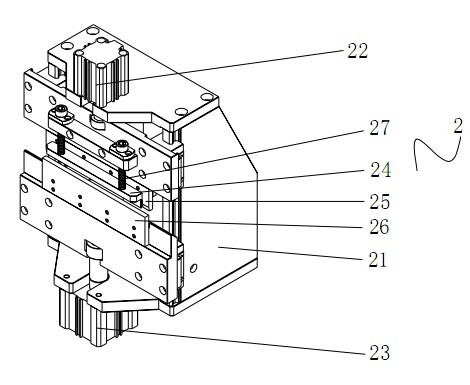

[0029] as attached Figure 2-8 As shown, a flexible packaging lithium battery automatic gluing machine includes a workbench 10 arranged on the frame, and a conveyor chain 101 is arranged on the workbench 10, and the conveyor chain 101 is driven by a motor to move circularly. There is a clamp 102. The clamp 102 is used to clamp the battery 20 to be glued. The clamp 102 is connected by a rotating shaft, and an elastic part and a protruding part are arranged on the rotating shaft. The clamp 102 drives the protruding part through a driving mechanism to drive the clamp 102 to open or Closed, the driving mechanism can be a cylinder; on the workbench 10, there are also a feeding mechanism 1, an edge trimming mechanism 2, a tape conveying mechanism 3, a gluing mechanism 4, a glue folding mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com