Main spindle box for milling and drilling machine

A spindle box, milling and drilling technology, applied to other manufacturing equipment/tools, metal processing machinery parts, maintenance and safety accessories, etc., can solve the problem that machine tool equipment cannot meet the processing requirements of complex parts, reduce temperature and ensure processing Accuracy, ingenious structure and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific drawings and embodiments.

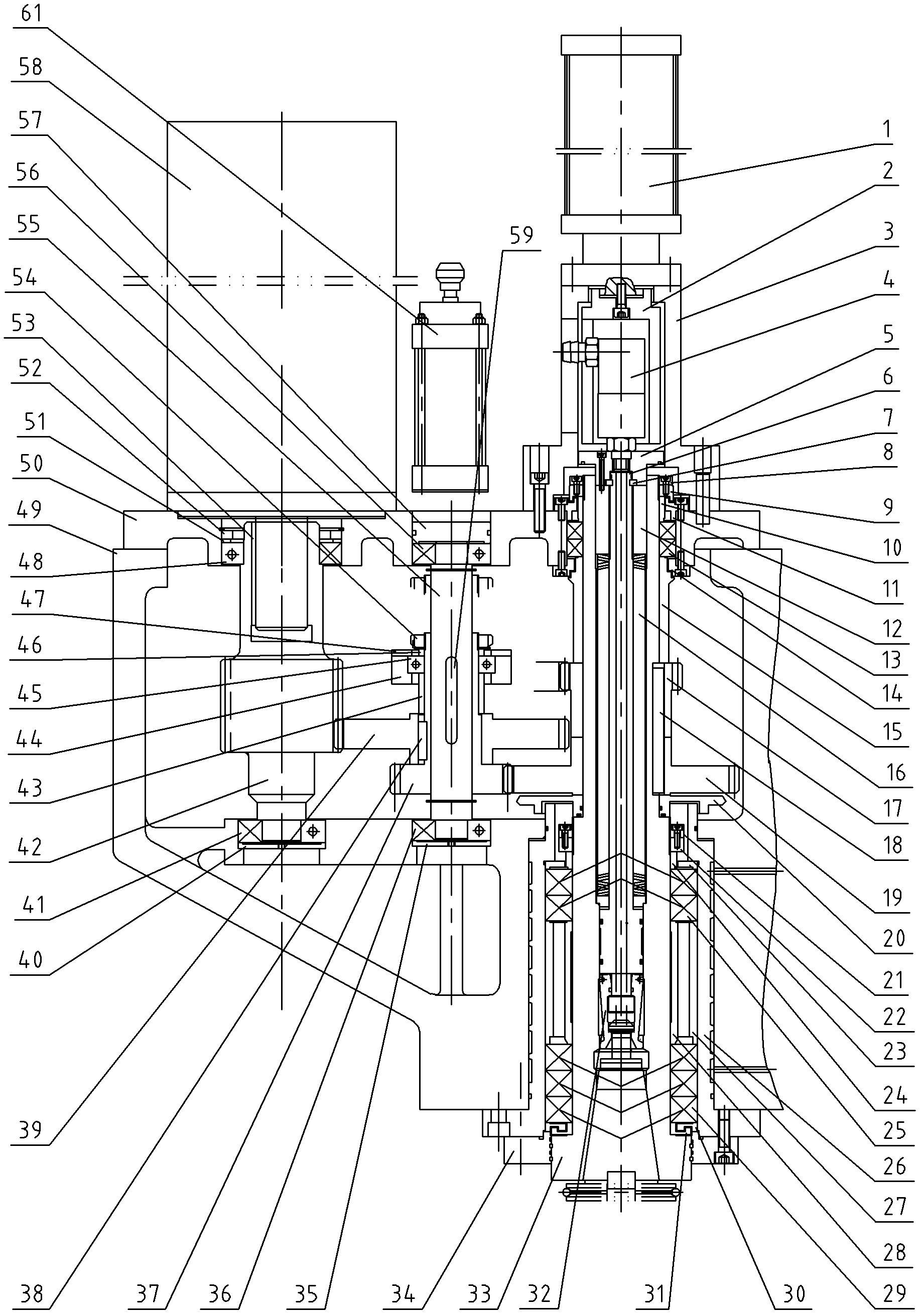

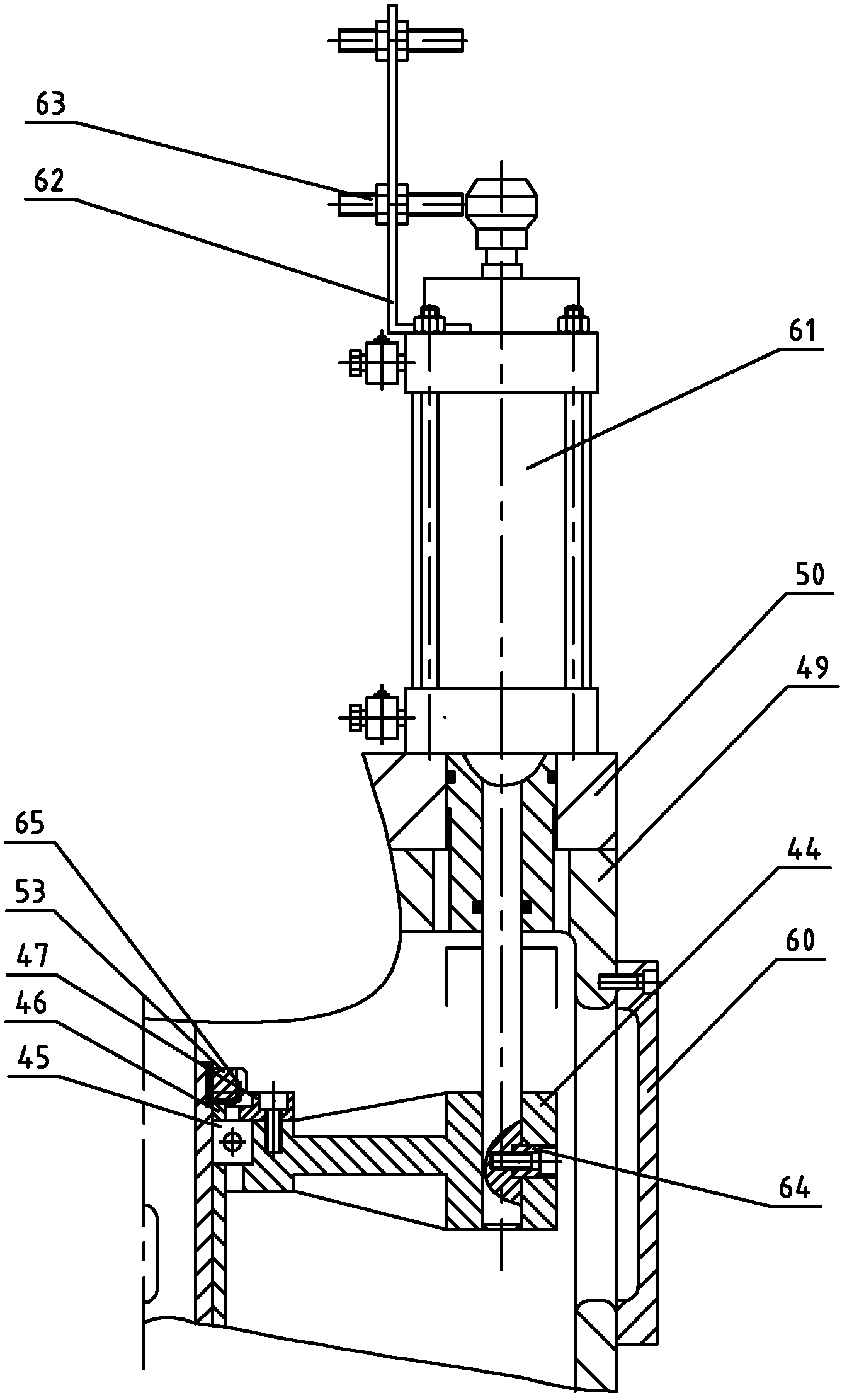

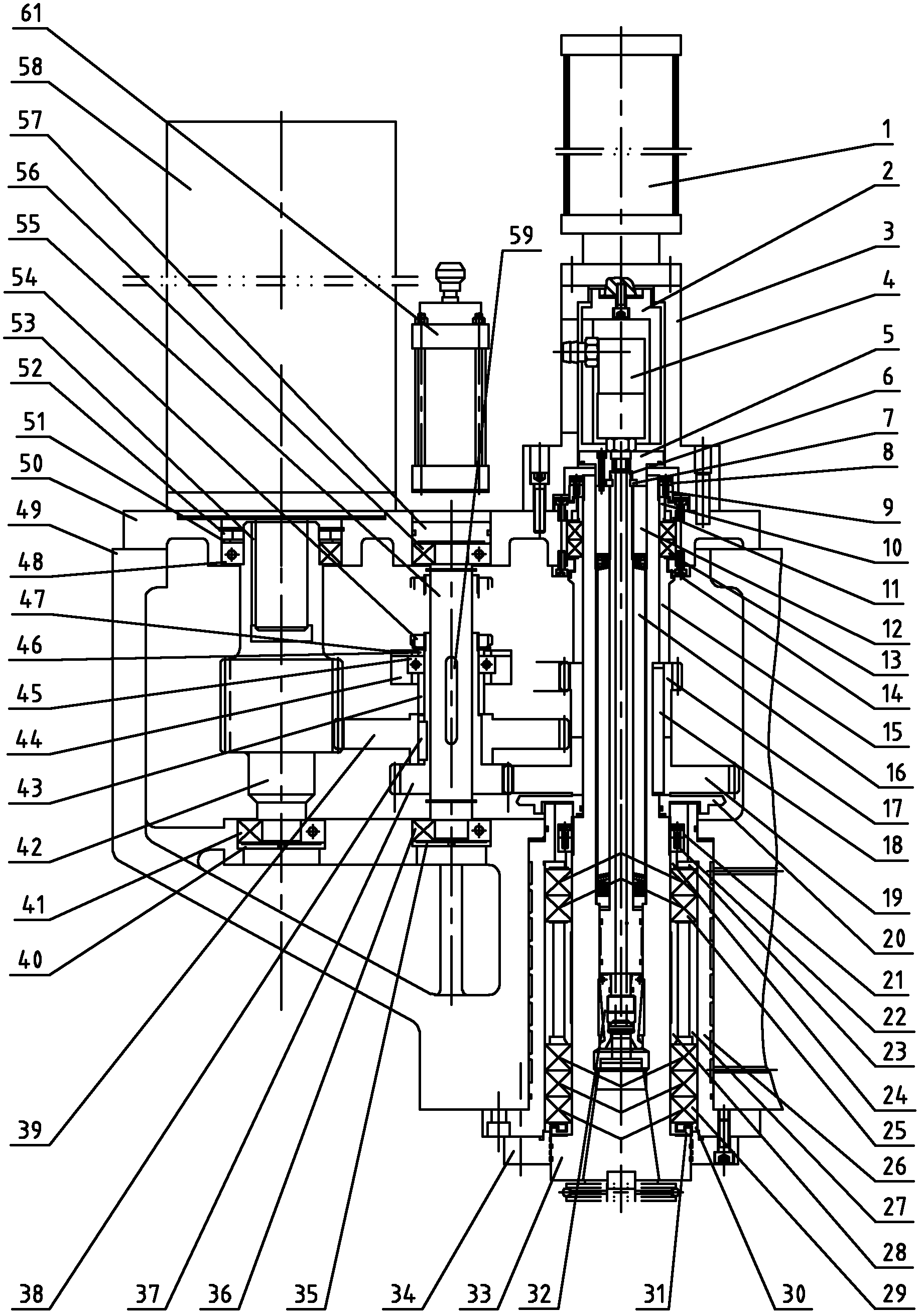

[0019] As shown in the figure: the present invention mainly consists of a booster cylinder 1, a pressure sleeve 2, a booster cylinder seat 3, a rotary joint 4, a cover 5, a pull rod 6, a spacer 7, a rear outer nut 8, a rear inner nut 9, and a spacer 10. Sealing cover 11, pull rod nut 12, support bearing group 13, bearing cover 14, spacer 15, butterfly spring group 16, small output gear 17, flat key 18, large output gear 19, spacer 20, front outer nut 21. Front inner nut 22, spacer 23, spacer 24, first bearing group 25, water jacket 26, outer spacer 27, inner spacer 28, second bearing group 29, outer spacer 30, inner spacer 31 , Claw 32, Main shaft 33, Flange cover 34, Take out pad 35, Lower bearing 36, Small transmission gear 37, Flat key 38, Large transmission gear 39, Take out pad 40, Lower bearing 41, Gear shaft 42, Spacer ring 43 , fork 44, bearing 45, pad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com