A new type of cutting power device

A power device and power component technology, which is applied in the field of new cutting power devices, can solve the problems of unsatisfactory compound processing and simple structure, and achieve the effect of multi-axis processing and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

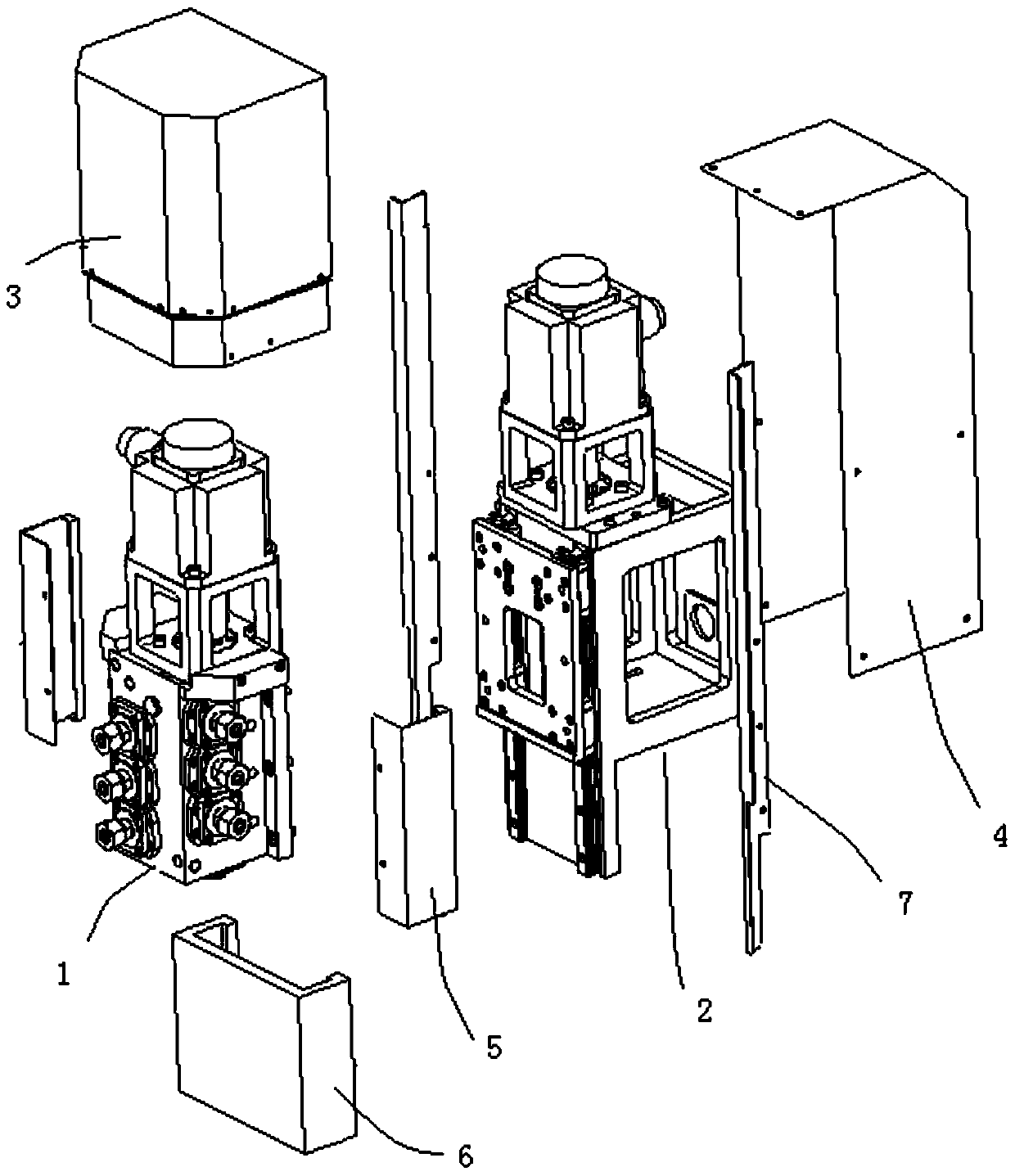

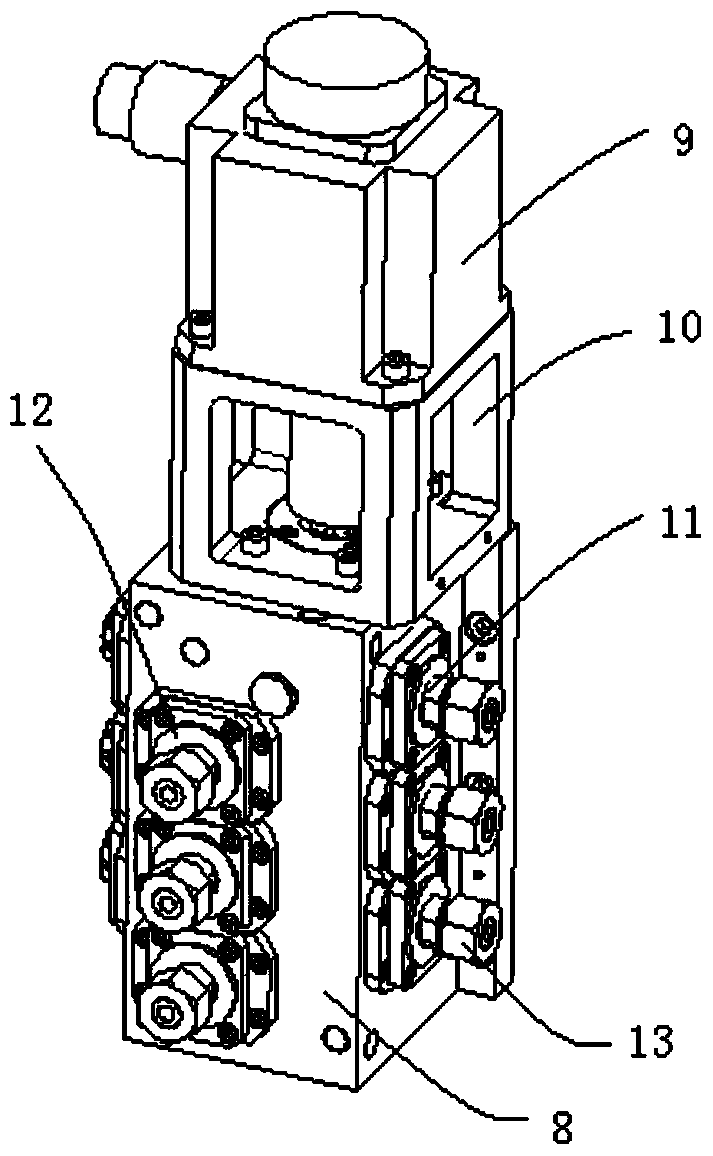

[0041] see figure 1 and image 3 , in order to accurately describe the spatial distribution of each component of the present invention, according to the industry practice of machining machine tools, three axes X, Y, and Z that are orthogonal to each other are defined in space. The positioning and orientation of the various components described in this article are relatively set according to the three defined axes, and do not constitute a specific direction limitation for the actual installation and use of the equipment. The embodiment of the present invention discloses a new type of cutting power device, which includes a multi-axis power assembly 1 and a Y-axis power device 2 for driving the multi-axis power assembly 1 to move on the Y-axis; the multi-axis power assembly 1 and the Y-axis power device 2 sliding connections;

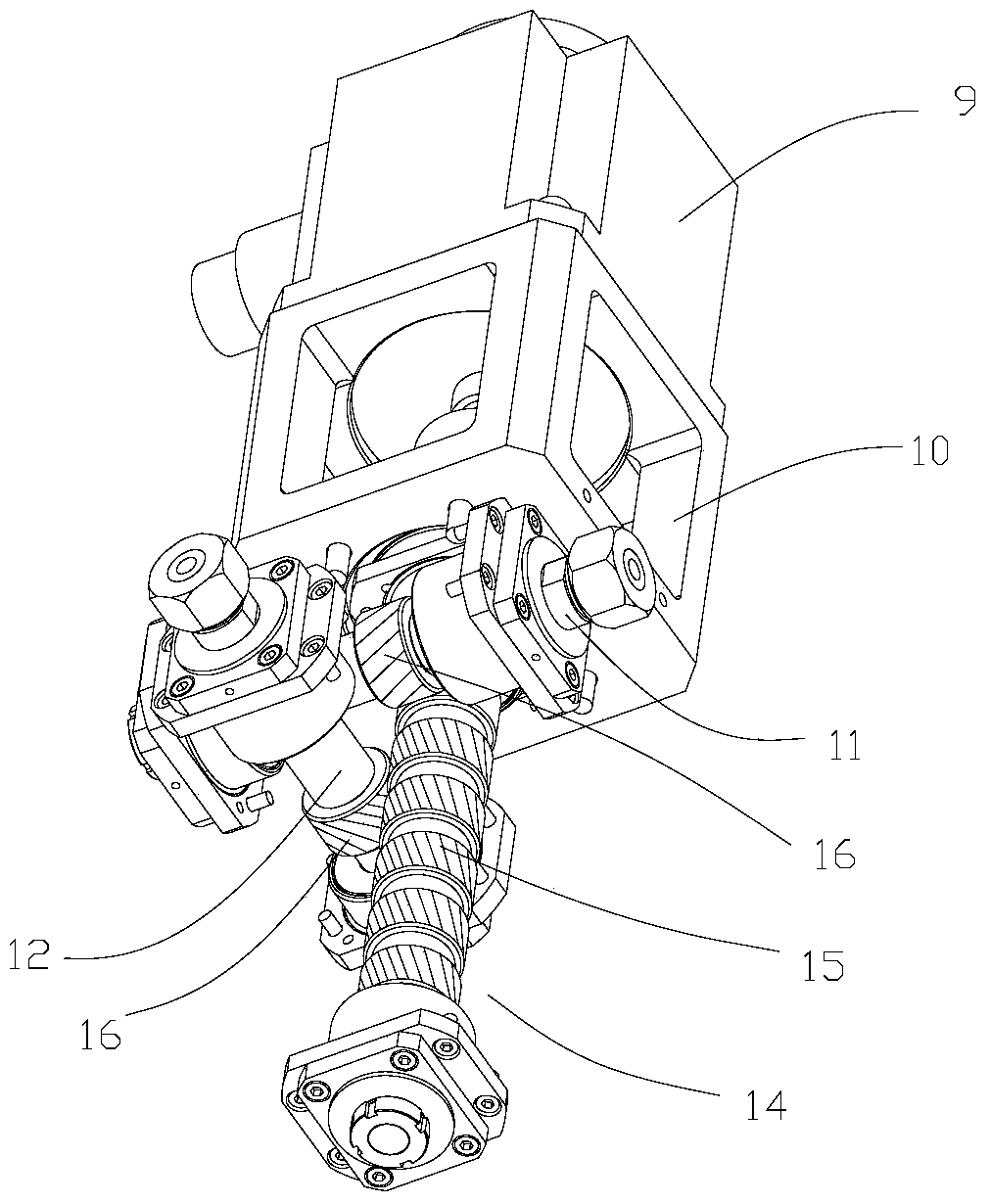

[0042] The multi-axis power assembly 1 includes a main shaft motor 9, a first motor base 10, a multi-axis housing 8, a transmission gear shaft 14, a dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com