Biomass gas generation system

A biomass gas generation system technology, applied in the manufacture of combustible gas, educts, petroleum industry, etc., can solve the problems of tar easily blocking pipelines and switches, secondary pollution, waste residue, tar water chaos and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention will be further described below in conjunction with specific drawings and embodiments.

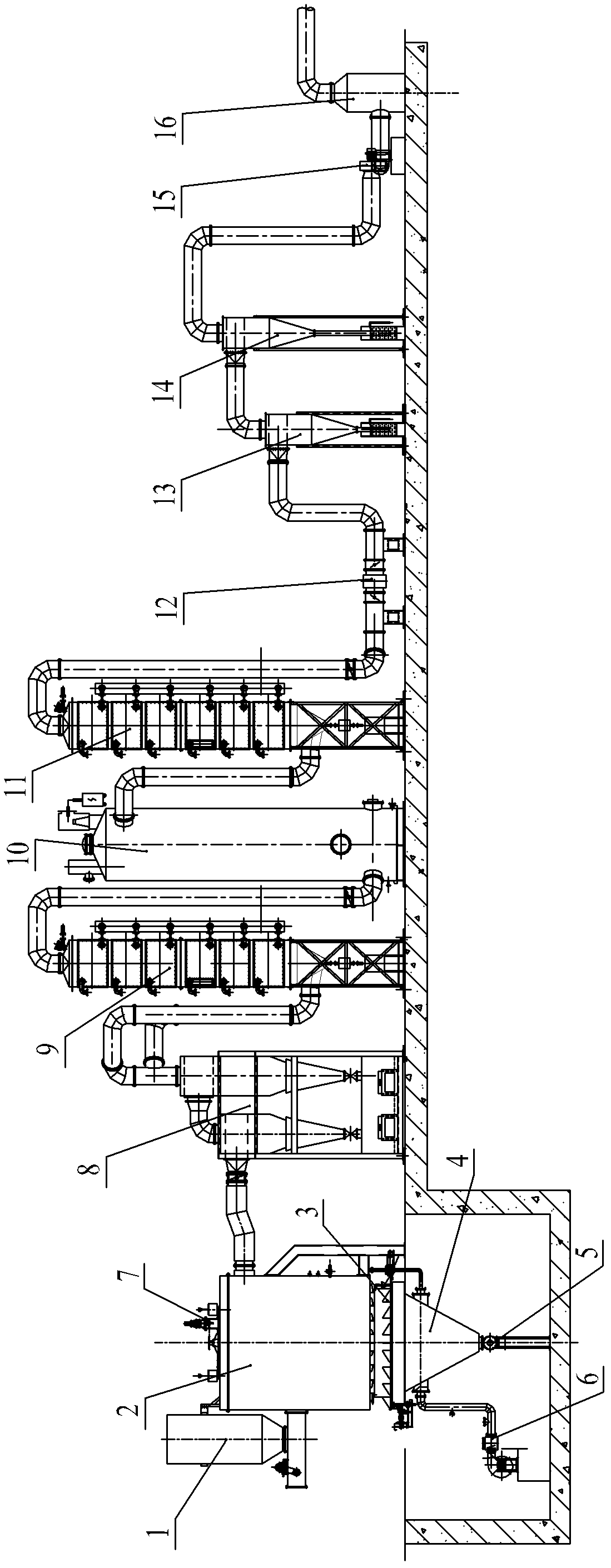

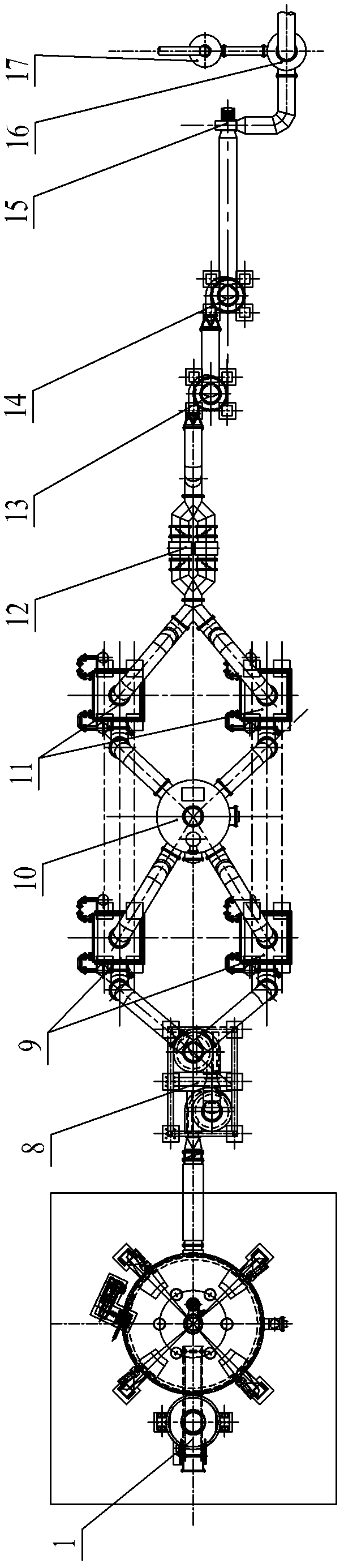

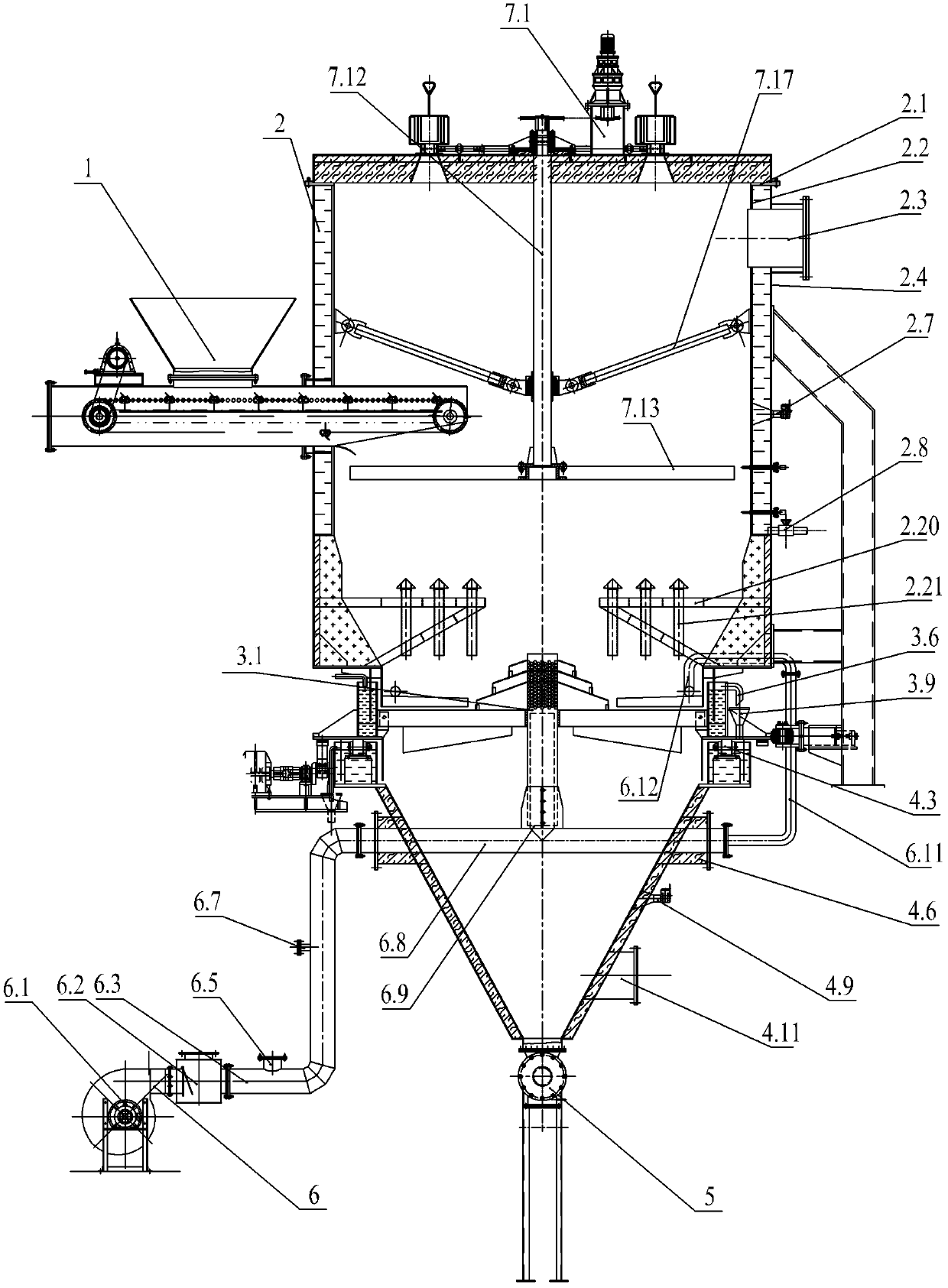

[0071] The biomass gas generation system in the embodiment mainly includes a feed device 1, a biomass gasifier, a post-processing system, and a gas transmission and storage pipeline system, which are connected in sequence according to the sequence of gas generation and treatment. The biomass gasifier It has a fuel inlet and a gas outlet, the combustion inlet is connected to the feed device 1, and the gas outlet is connected to the post-processing system through a connecting pipe; the post-processing system includes a cyclone dust removal device 8, a first-stage tubular intercooler 9, and an electric tar catcher. device 10, secondary tube-type intercooler 11, filtration and purification device 12, primary water-gas separator 13 and secondary water-gas separator 14, and the inlet of cyclone dust removal device 8 passes through connecting pipe fittings and the fuel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com