Motor traveling elevator

An elevator and electric technology, applied in the direction of lifting frame, lifting device, conveyor objects, etc., can solve the problem that the body cannot be accurately placed on the ground conveyor, but can only be placed on the ground static conveyor, etc., to achieve a high degree of automation and process. Reversible, well-structured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific drawings and embodiments.

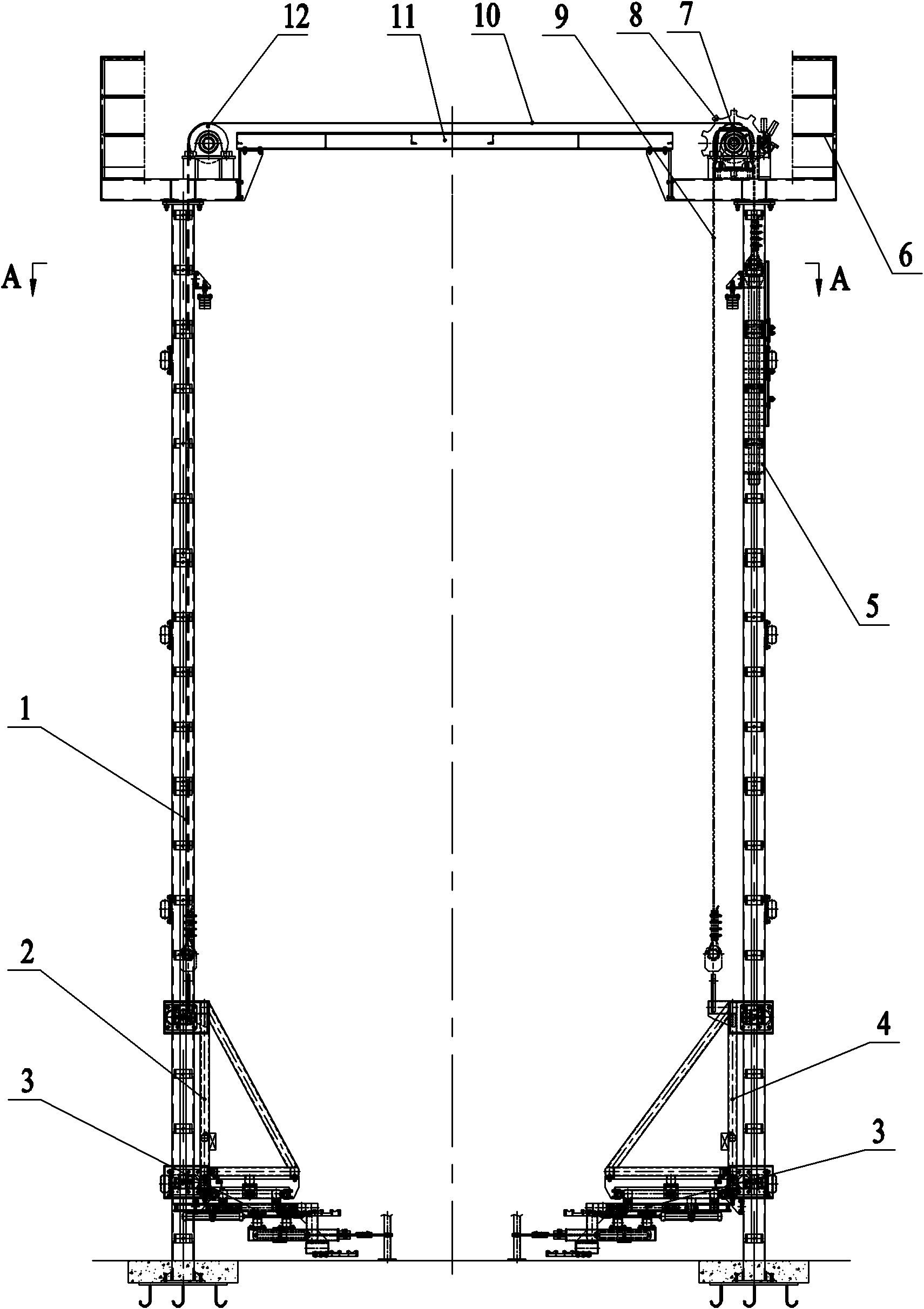

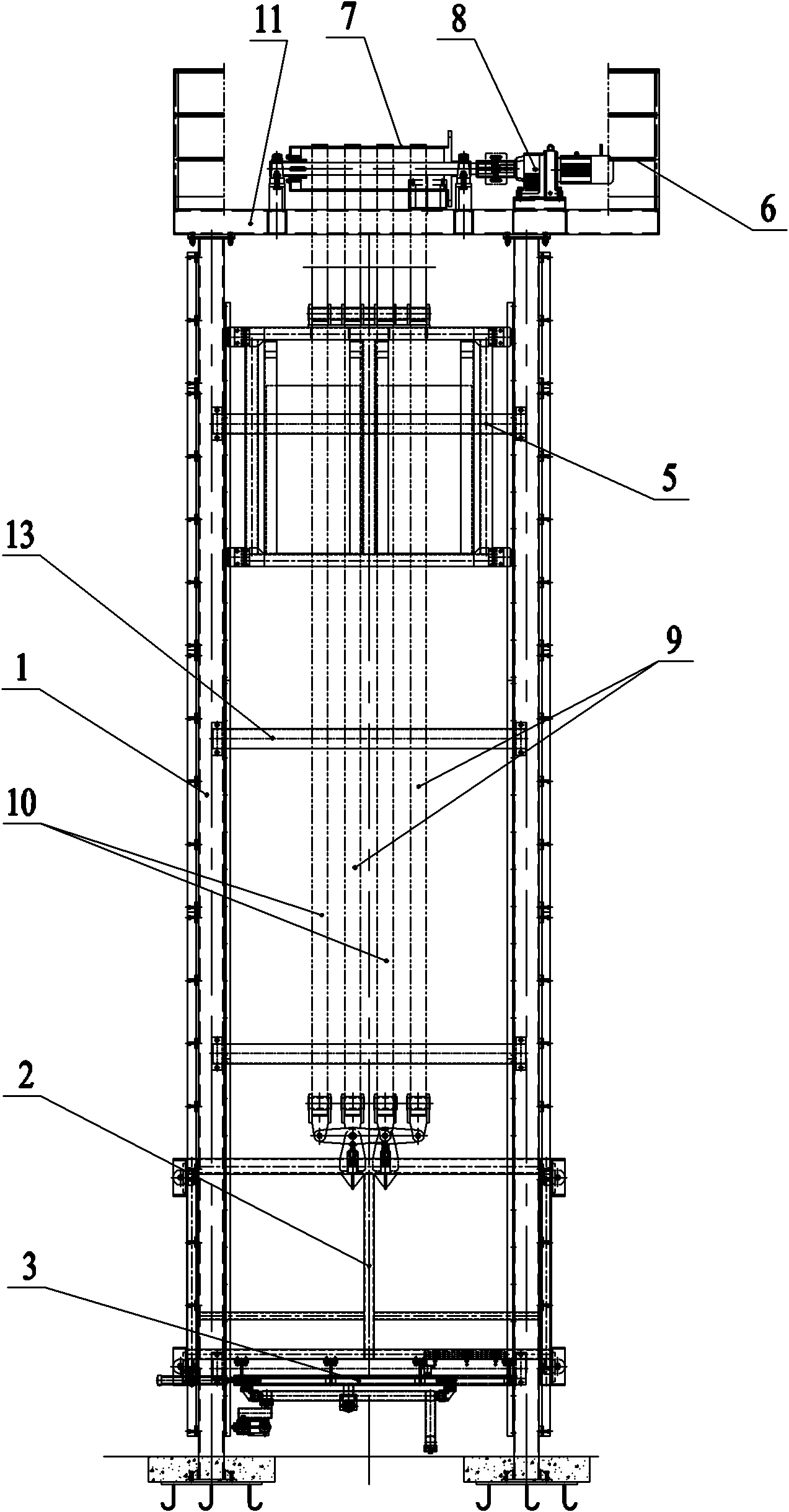

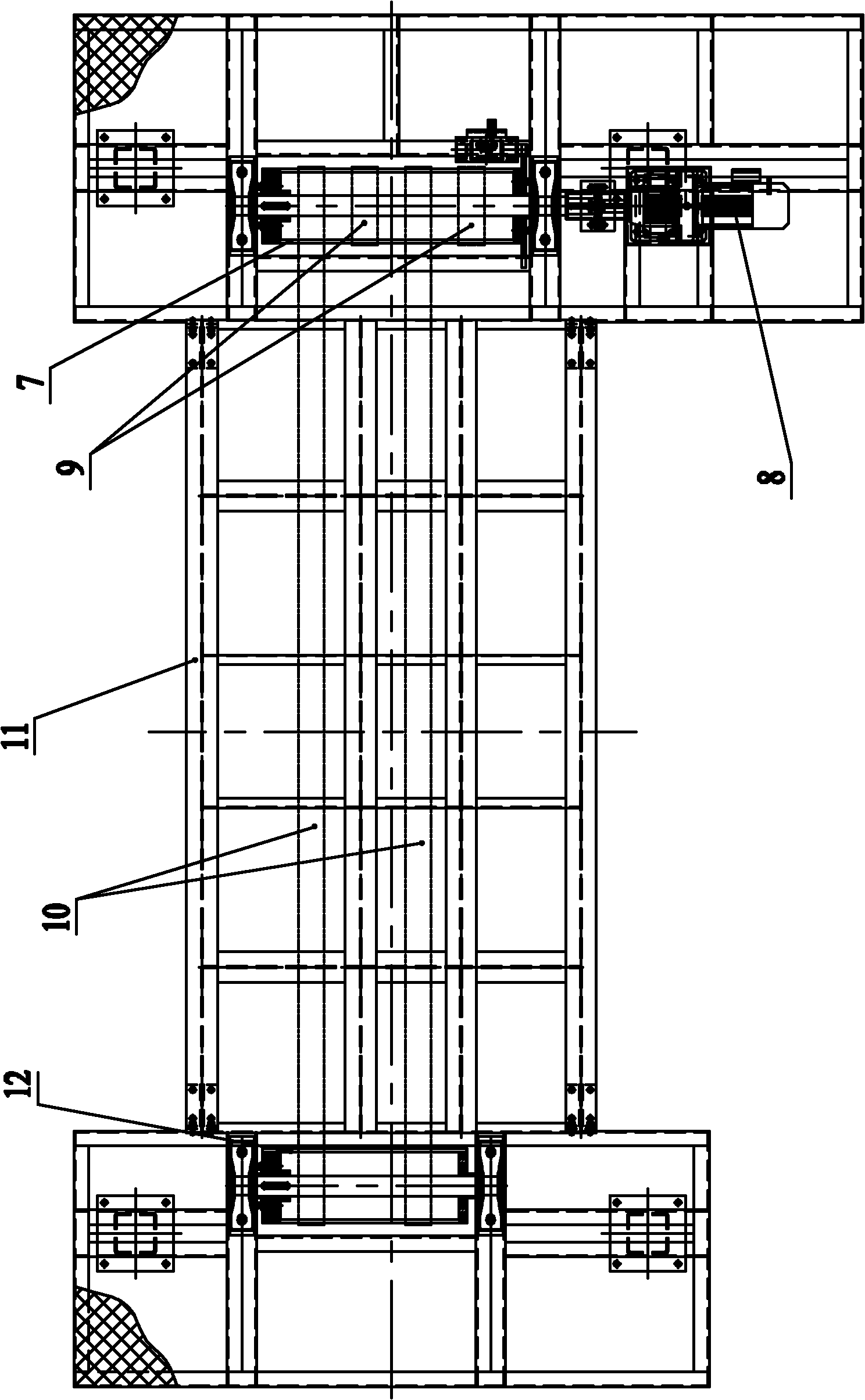

[0018] Such as Figure 1~Figure 3 As shown: the electric accompanying elevator in the embodiment is mainly composed of a column 1, a left support 2, an accompanying mechanism 3, a right support 4, a counterweight assembly 5, a guardrail 6, a driving drum 7, a driving motor 8, a first belt 9, a second Belt 10, top frame 11 and driven roller 12 form. There are four columns 1, and the four columns 1 are welded and fixed to the embedded board on the ground; connecting beams 13 are provided between the two columns 1 on both sides, and the connecting beams 13 are used to strengthen the firmness of the overall frame structure of the elevator. Top frame 11 utilizes screw to be installed on column 1 top, and driving drum 7, driven drum 12 utilizes bolt member to be fixedly installed on top frame 11 both sides respectively, and driving drum 7 is driven by drive motor 8....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com