Cassava pulling up and holding mechanism

A clamping mechanism and cassava technology, applied in harvesters, digging harvesters, agricultural machinery and implements, etc., can solve the problems of heavy labor, low production efficiency, immature technology, etc., and achieve simple operation, reasonable and ingenious structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

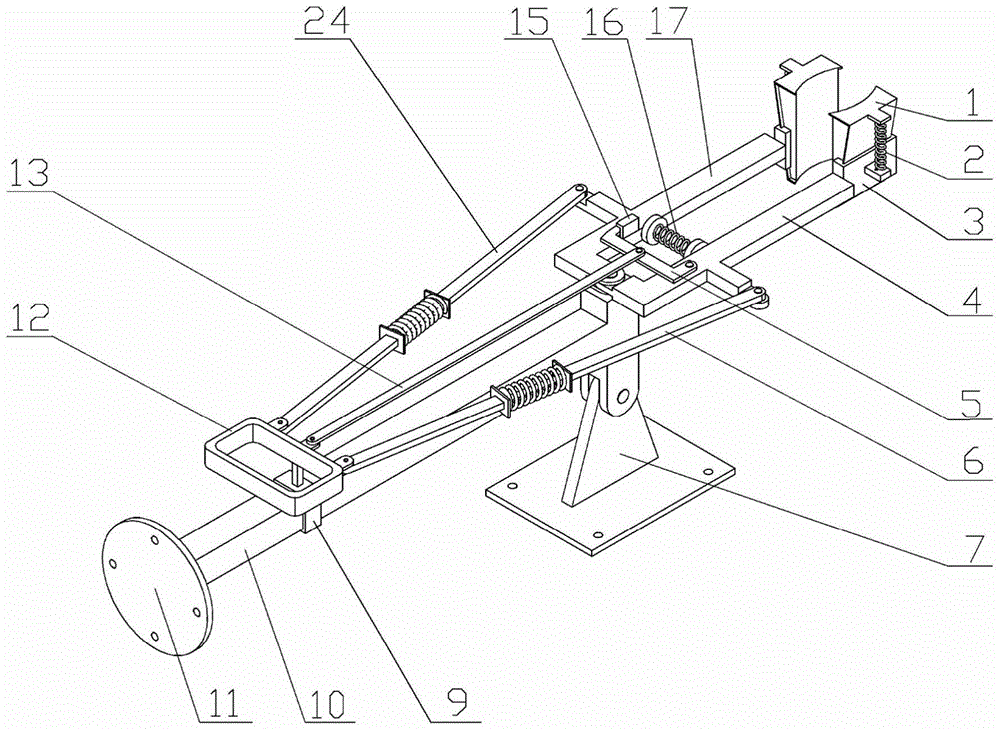

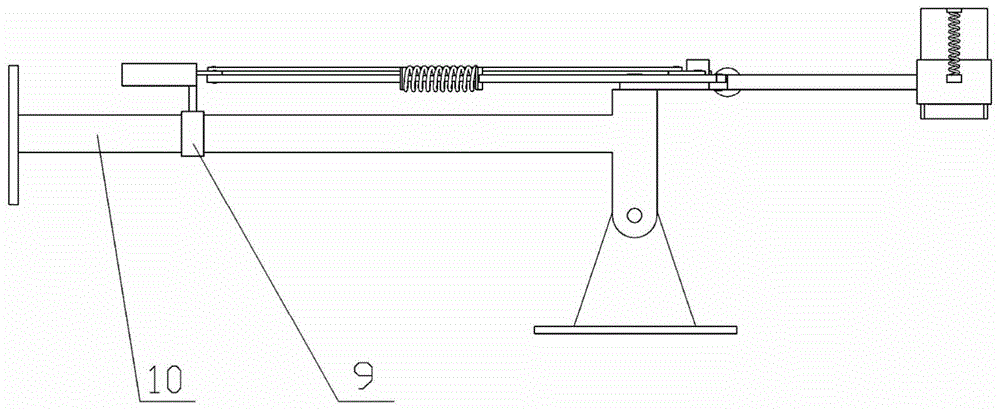

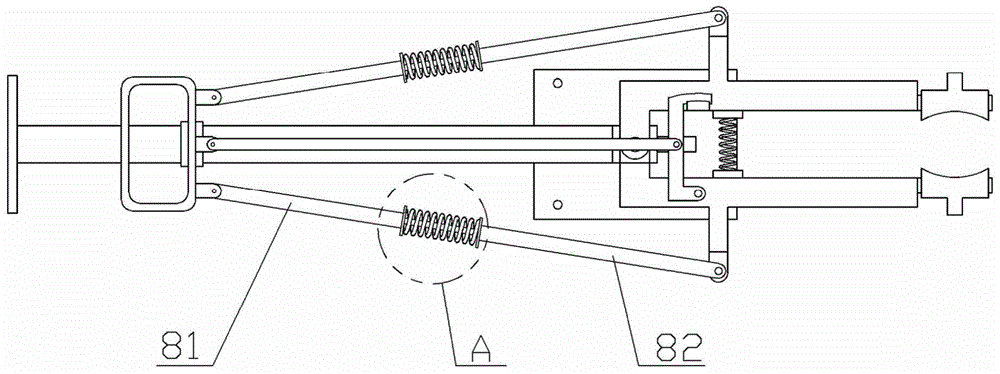

[0024] A cassava pulling and clamping mechanism according to the present invention includes a force applying rod 10, a support seat 7, a left clamping rod 17, a right clamping rod 4, a left guide block 21, a right guide block 3, and a first left return position. Spring 2, the first right return spring 23, the third return spring 16, the fixed buckle 15, the hook 5, the left pull rod 24, the right pull rod 6, the handle 12, the middle pull rod 13, the specific structure and connection method are:

[0025] The lower part of the front end of the applying force rod 10 is installed on the support base 7 through a hinge, and the upper part of the front end of the applying force rod 10 is symmetrically installed with a left clamping rod 17 and a right clamping rod 4 through a hinge; the left clamping rod 17 and the right clamping rod 4 The front end is provided with a left guide block 21 and a right guide block 3; the left clamping block 22 and the right clamping block 1 are respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com