Crossed column assembling machine

A technology of assembling machine and cross column, applied in resistance welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of complex positioning mechanism, reduce labor intensity, ingenious and reasonable structure, improve production quality and production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with specific drawings and embodiments.

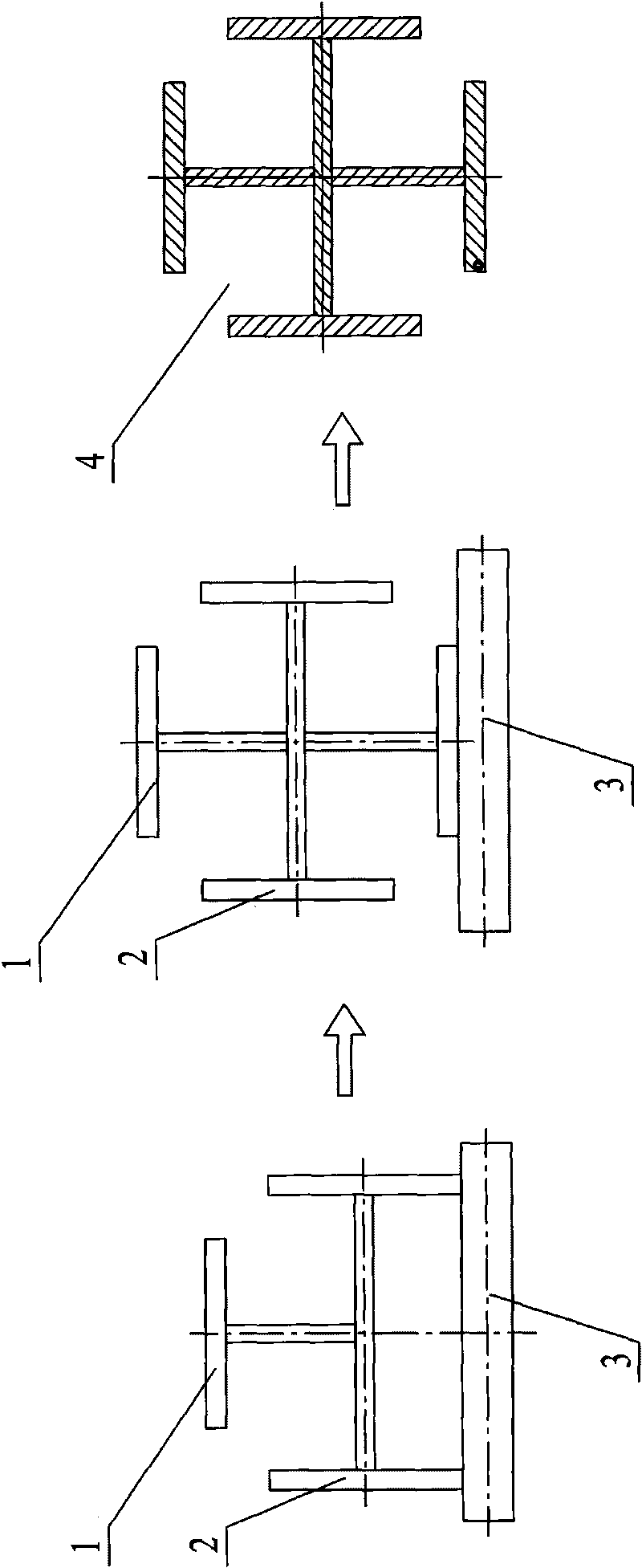

[0028] like figure 1 As shown, the cross column is welded twice by one H-shaped steel 2 and two T-shaped steels 1. First, the web of one T-shaped steel 1 is welded to the middle of the web of H-shaped steel 2, and then the other The web plate of T-shaped steel 1 is welded and fixed to the other side of the middle part of the web plate of H-shaped steel 2 to form a cross column.

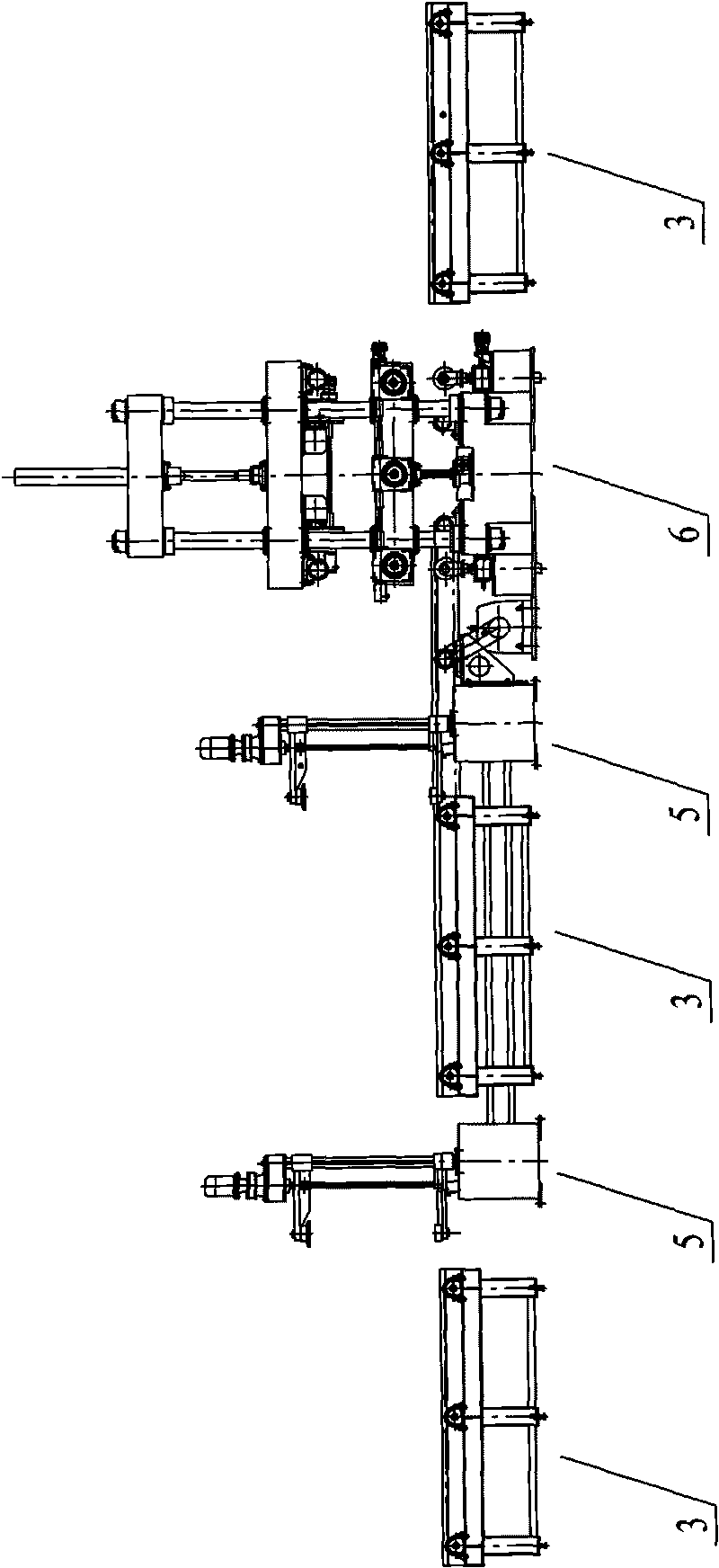

[0029] like figure 2 As shown, the cross column erecting machine of the present invention is a special equipment for splicing H-shaped steel 2 and T-shaped steel 1 into a cross column. control system, the transmission device 3 is used to transfer the H-shaped steel 2 and T-shaped steel 1 to the main machine 5 for assembly and transmit the assembled cross column; the pre-centering device 4 is used to transfer the H-shaped steel 2 and T-shaped steel before splicing The section steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com