Automatic on-line balancing system of liquid-injection high-speed main shaft

A high-speed spindle and automatic balancing technology, applied in the field of high-speed dynamic balancing equipment, can solve the problems of limiting machining production efficiency, long balancing time, and complicated operation, and achieve the effect of being beneficial to industrial field application, simple structure and high balancing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is described in further detail below in conjunction with accompanying drawing:

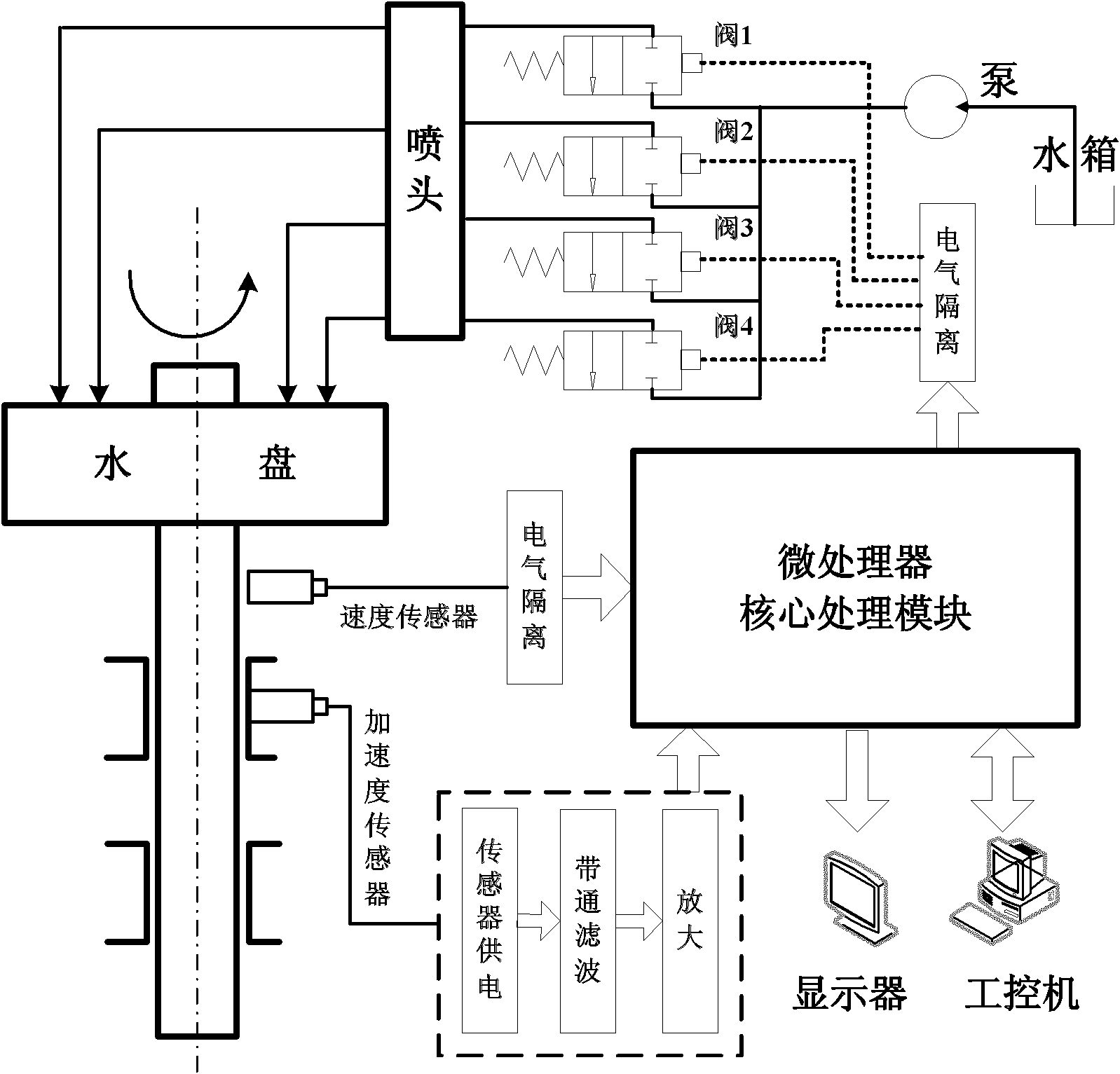

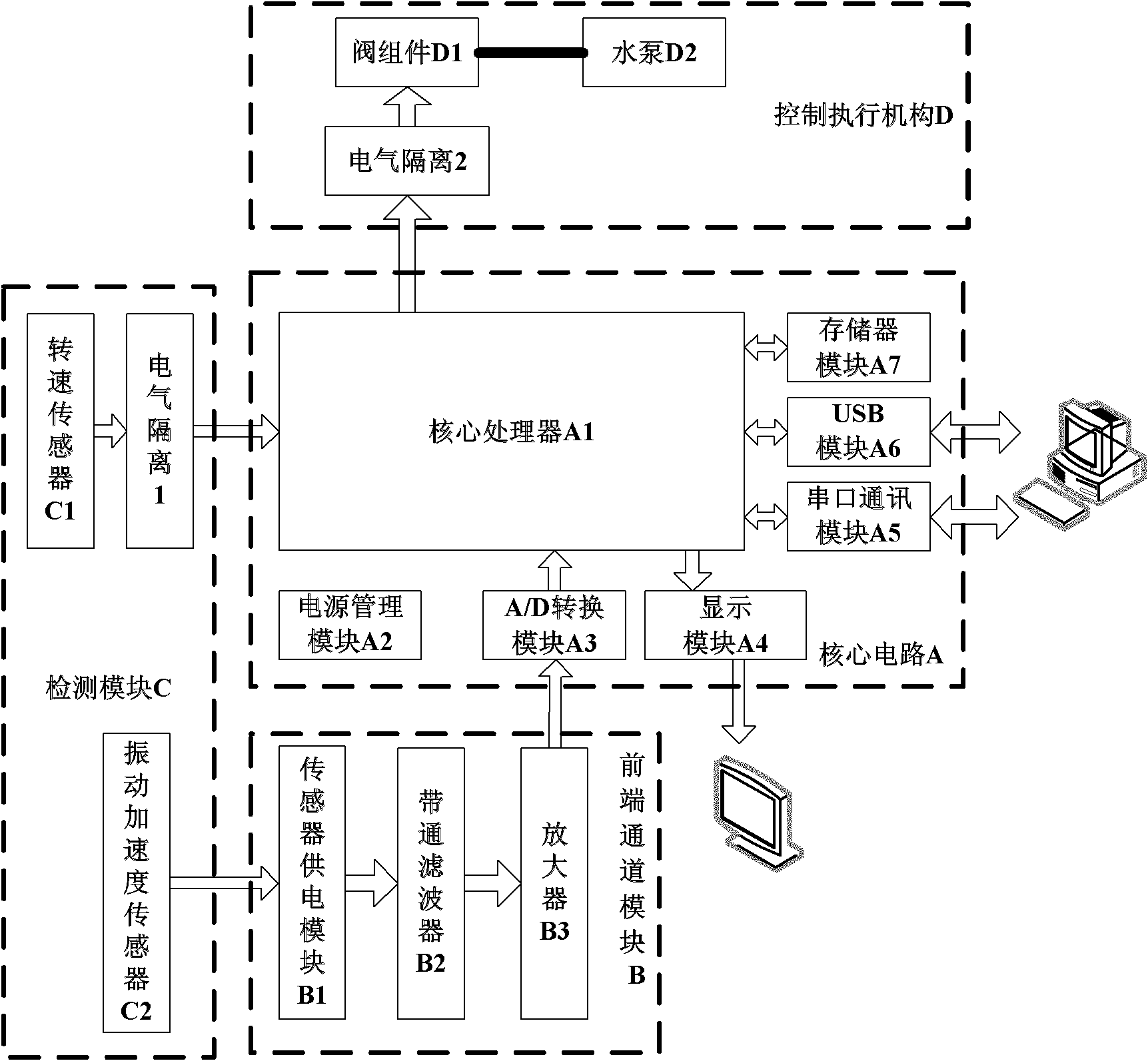

[0036] see figure 1 , the liquid spray type high-speed spindle online automatic balancing system of the present invention is composed of a mechanical structure part and an electrical control part. The following is a detailed description of these two parts:

[0037] (1) Mechanical structure

[0038] Figure 8 The liquid spray type high-speed spindle online automatic balancing system designed for the present invention is applied to the schematic diagram of the mechanical structure assembly in the example. It can be seen from the figure that the mechanical structure part of the present invention includes two parts: the water tray structure and the nozzle structure:

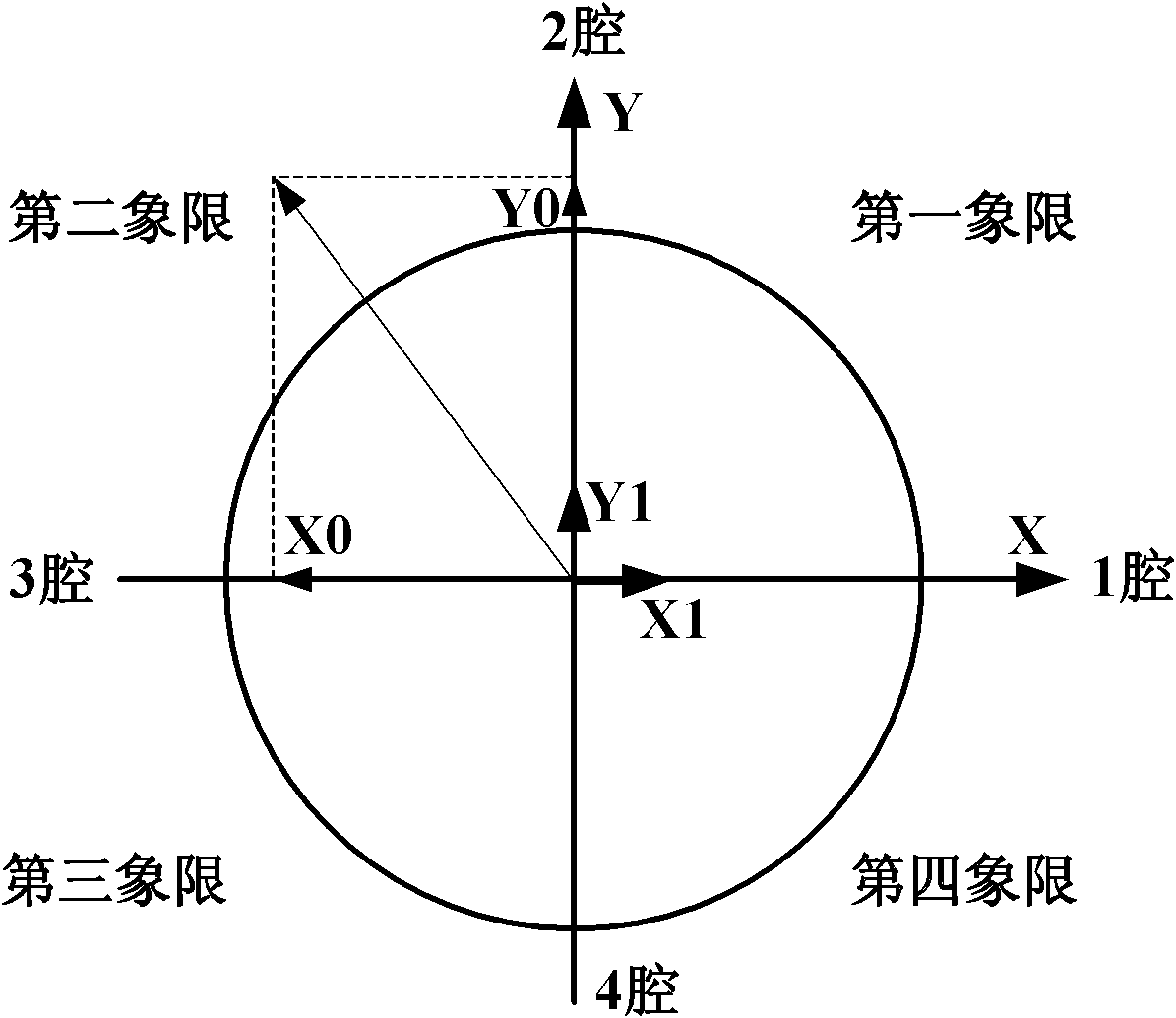

[0039] The assembly effect of the water tray structure is as follows Figure 4 The structure of the water pan is divided into two parts: the outer ring of the water pan 1 and the inner ring of the water pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com