Porous metallic beryllium deep-hole machining method

A processing method and metal beryllium technology, applied in metal processing equipment, metal processing mechanical parts, boring/drilling and other directions, can solve the problems of tool wear, tool erosion, difficult to ensure machining accuracy, etc., to improve machining accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

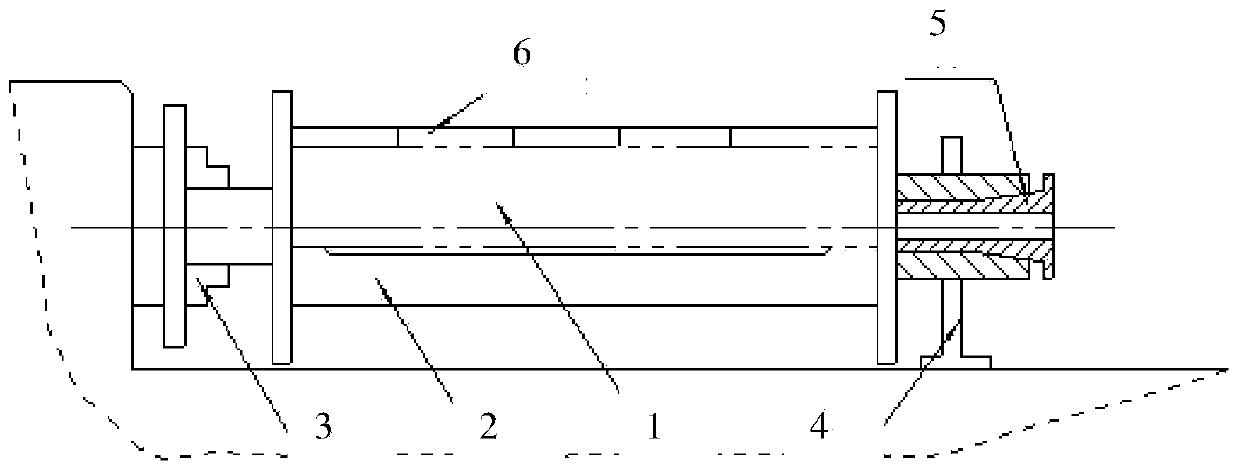

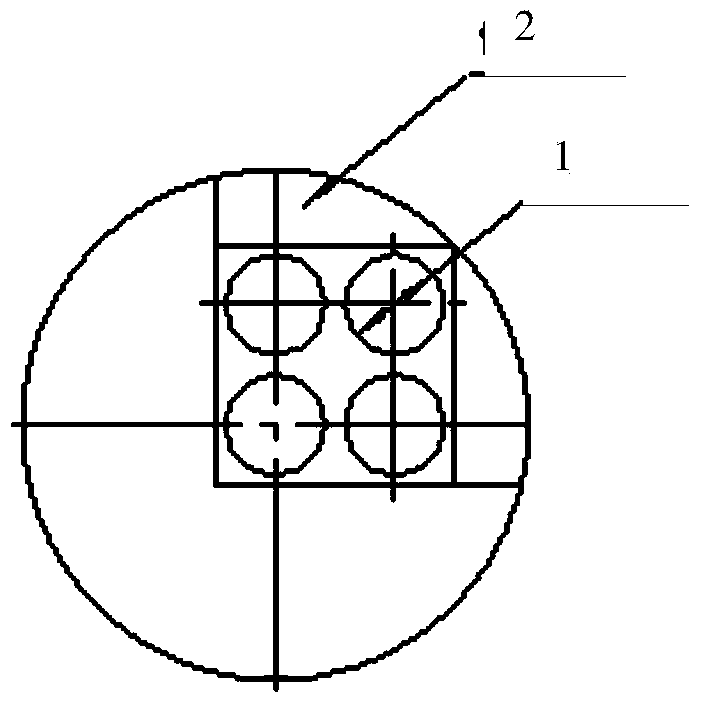

[0025] Considering that beryllium is brittle and easy to crack, the tool guide block will strongly squeeze the hole wall of the workpiece during deep hole drilling. In order to reduce the cutting force and extrusion force, avoid drilling cracks in the workpiece, and the machine tool cannot withstand the chip force generated by one drilling, the invention provides a drilling (φ20mm)-multi-stage reaming (φ24, φ26, φ28, φ30 , φ32mm) - deep hole drilling process of reaming and equipment for operating this process, especially suitable for deep hole processing of metal beryllium with large aperture (≥32mm) and large aspect ratio (50~150). The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0026] 1. According to the size and shape of the beryllium workpiece to be processed, design and manufacture eccentric fixtures, tool guide sleeves, drill bits, drill pipes, and connecting threads between drill bits a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com