High-precision integrated laser de-weight automatic balancing device and method

A laser deweighting and automatic balancing technology, applied in static/dynamic balance testing, measuring devices, instruments, etc., can solve the problems of low balancing accuracy, low balancing efficiency, damage to the surface quality of the rotor, etc., to improve the balancing efficiency, The effect of improving balance accuracy, improving work performance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

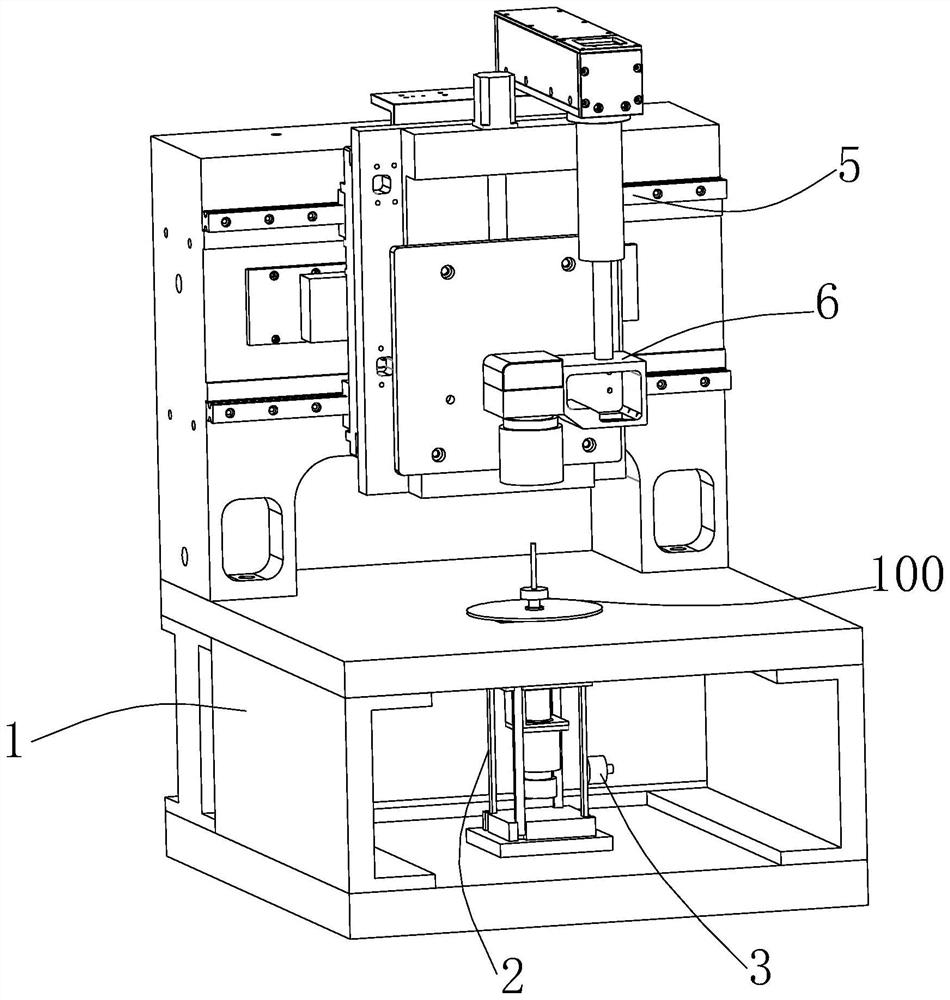

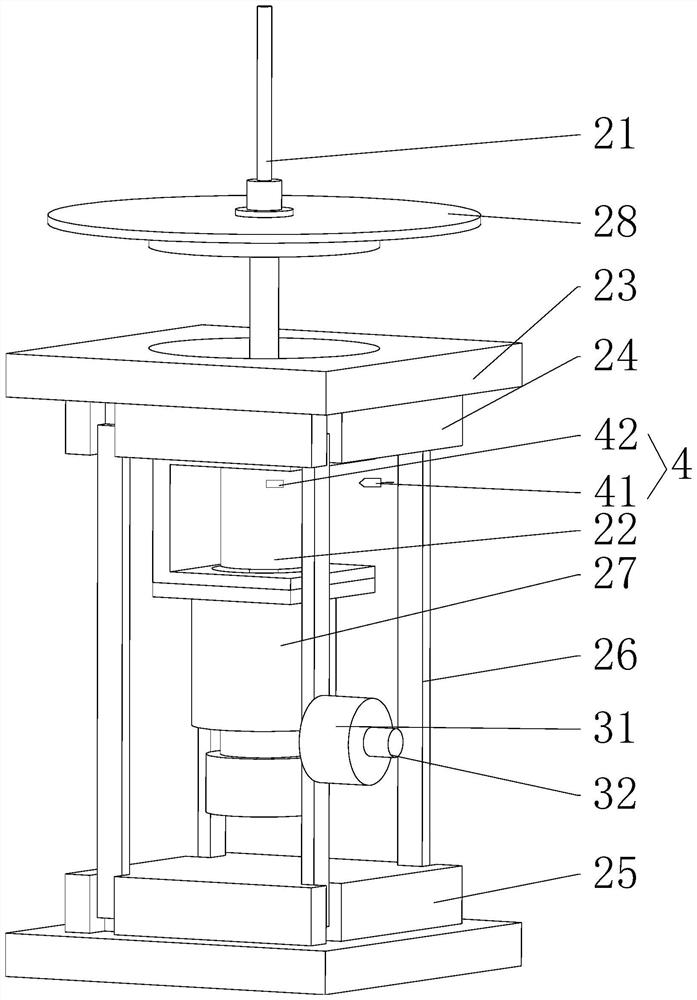

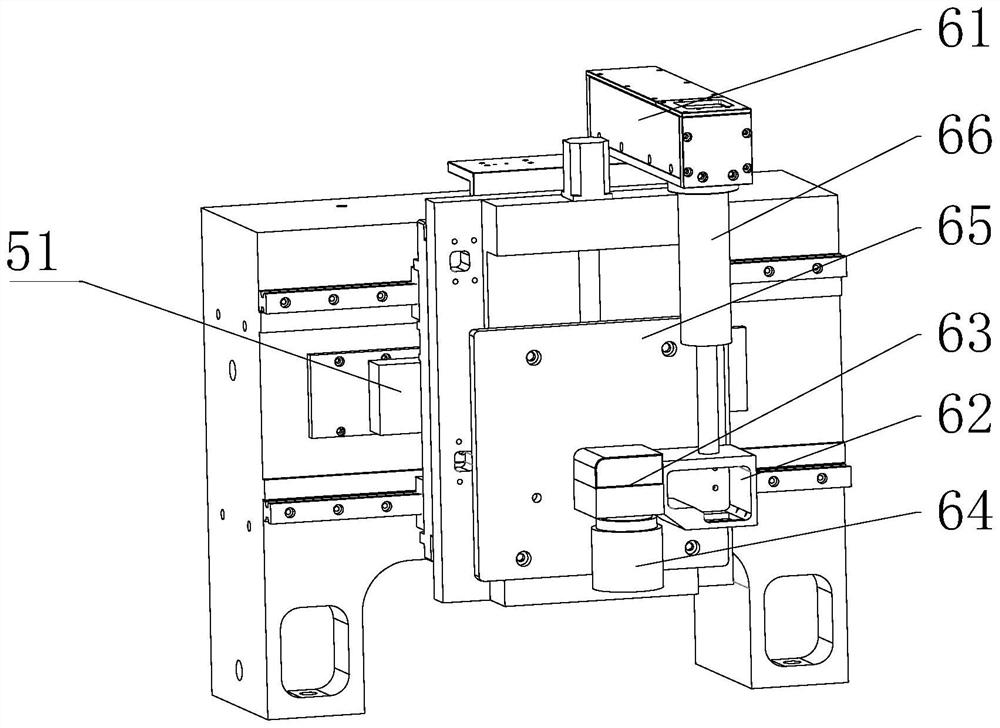

[0041] See figure 1 and figure 2 , the present invention has an equipment support mechanism 1, a vibration transmission mechanism 2, a vibration detection mechanism 3, a reference phase detection mechanism 4, an automatic alignment mechanism 5, and a laser weight removal mechanism 6; the equipment support mechanism 1 is provided with a A vibration transmission mechanism 2 that vibrates at times, a vibration detection mechanism 3 for detecting vibration and a reference phase detection mechanism 4 are fixed on the vibration transmission mechanism 2, and an automatic alignment mechanism for automatic alignment is arranged above the vibration transmission mechanism 2 5. The automatic alignment mechanism 5 is provided with a laser deweighting mechanism 6 .

[0042] The equipment support mechanism 1 includes a base 11 and a column 12 fixed on the base 11; the vibration transmission mechanism 2 includes a rotating shaft 21, a coupling 22, a bearing seat 23, an upper connecting plat...

Embodiment 2

[0047] See Figure 4 , a dynamic balancing method using an integrated laser deweighting automatic balancing device using a disc rotor, comprising the following steps:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com