Integrated liquefied gas filling opening (valve) capable of being quickly dismounted inside

A liquefied gas, integrated technology, applied in the direction of control valve, valve device, functional valve type, etc., can solve the problem that reliability and safety cannot be effectively controlled, the use of liquid filling port, the increase of maintenance cost, and the reliability of liquid filling. problems such as poor stability and poor stability, to achieve the effect of facilitating daily maintenance, convenient and quick assembly and disassembly, and improving reliability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

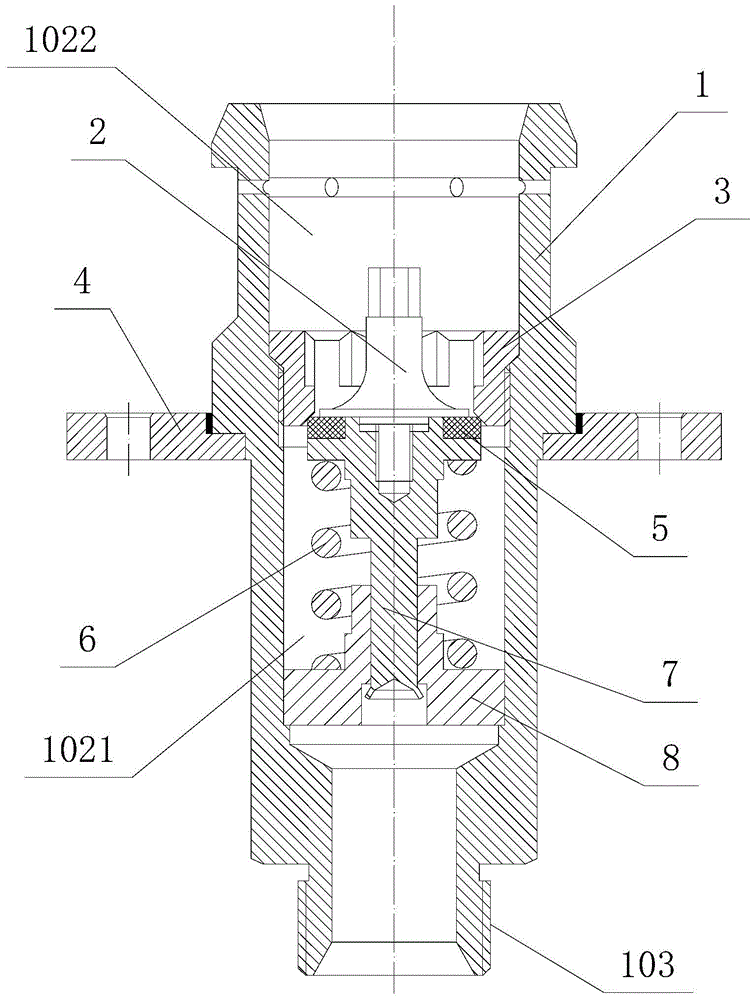

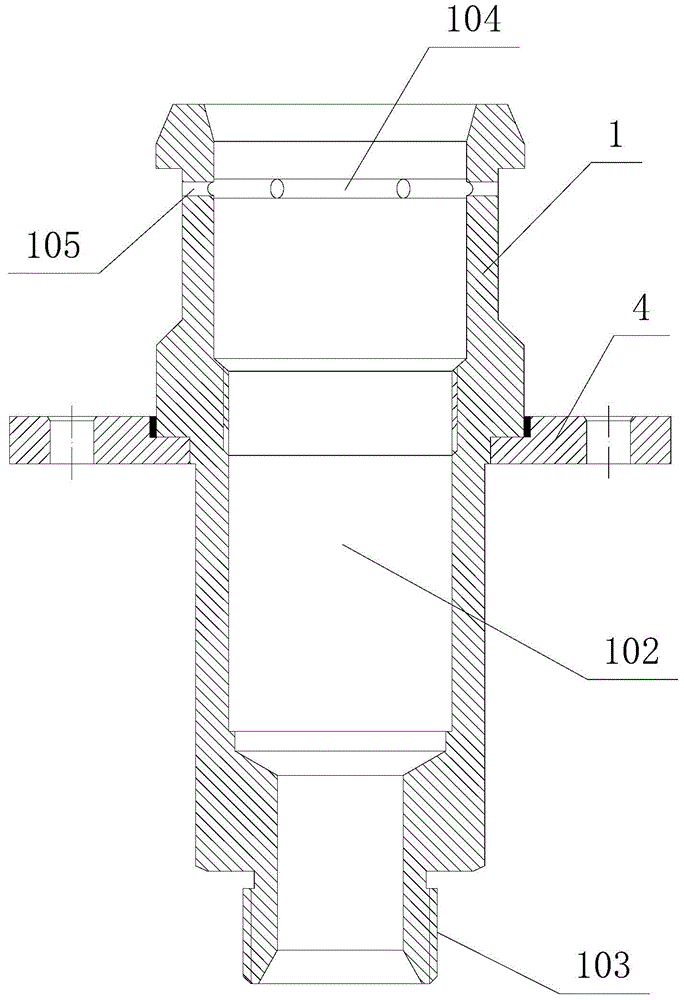

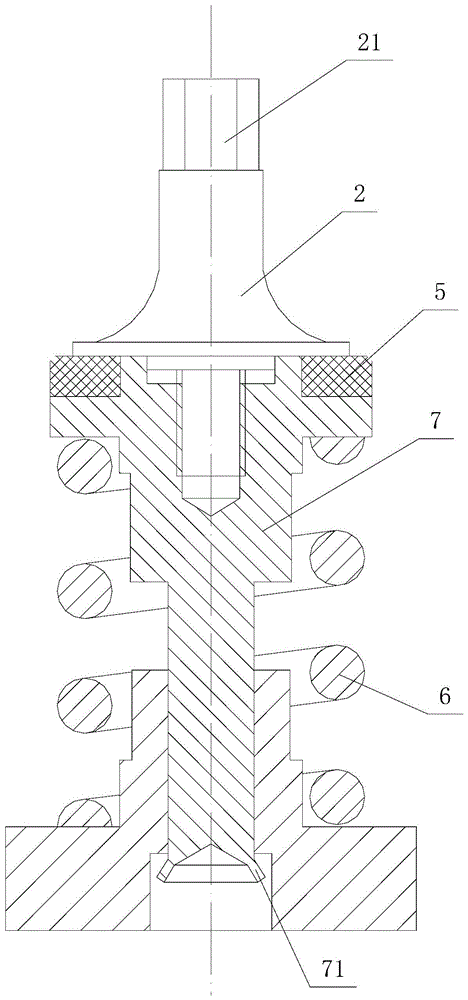

[0027] refer to Figure 1 to Figure 6 , the present invention provides a quick internal disassembly integrated liquefied gas filling port (valve), including a valve body 1, a valve seat 3 and a valve core assembly;

[0028] refer to figure 1 and figure 2 , there is a connecting flange 4 on the outside (side wall) of the valve body 1, which can be welded or integrally formed. There are installation holes and protective cover fixing screw holes evenly distributed on the connecting flange around the circumference, and the gas outlet end of the lower end of the valve body 1 There is an external thread 103 connecting with the outside, and the oblique opening of the inner hole is sealed with the outside. The upper and lower ends of the valve body 1 run through a stepped hole with a large upper end and a small lower end. In this embodiment, the stepped hole consists of three internal diameters. Different hole configurations, the stepped hole forms the valve cavity 102;

[0029] r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com